Manufacturing method of glass, optical glass, glass material for press molding, optical element, and their manufacturing method

A manufacturing method and optical glass technology, applied in optical components, glass manufacturing equipment, optics, etc., can solve the problems of heat-resistant material erosion, refractive index change, glass coloring, etc., to reduce erosion, suppress refractive index changes, The effect of reducing the amount of volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0515] First, in order to obtain optical glasses with the compositions shown in Tables 1-1 to 1-3, Tables 2-1 to 2-10 and Tables 3-1 to 3-3, boric acid, oxides, carbonates, and sulfates Weigh and mix glass raw materials. As the carbonate, lanthanum carbonate, zinc carbonate, and barium carbonate were used, and as the sulfate, zinc sulfate, barium sulfate, and the like were used. In addition, it is preferable that no glass raw material is introduced into any of Sb, As, and nitrate.

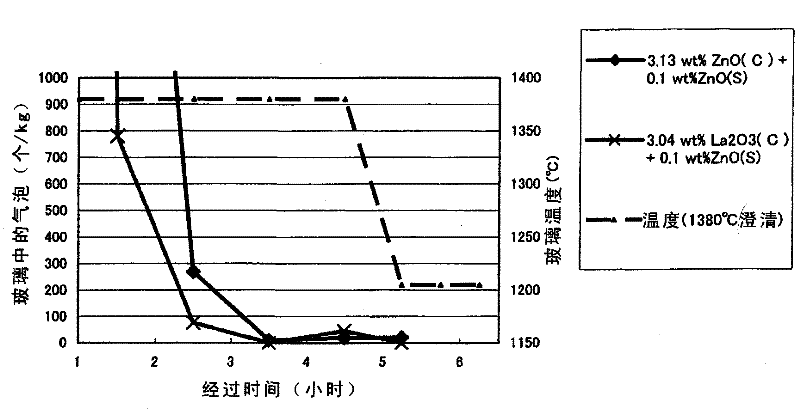

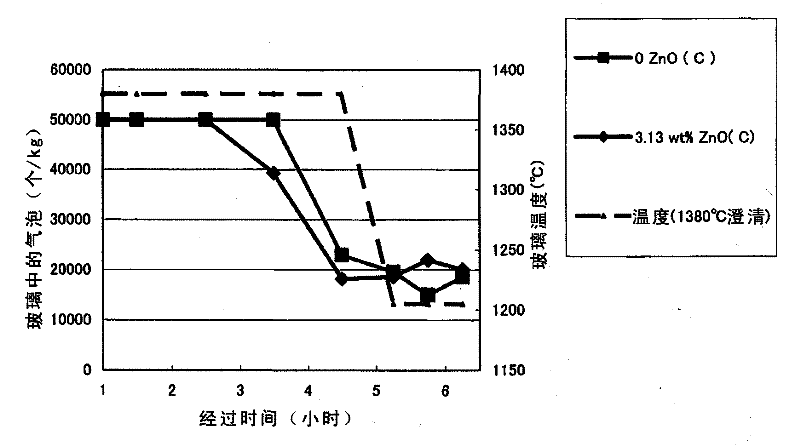

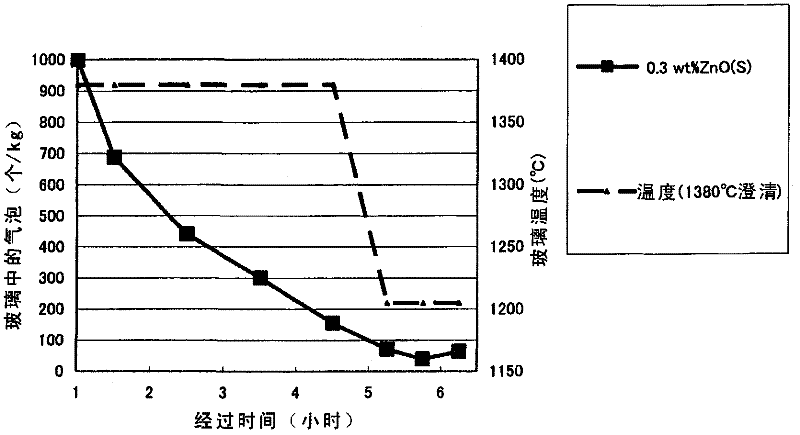

[0516] Suppose the quality of the obtained optical glass is a, and the amount of carbon introduced into the glass raw material in the form of carbonate is converted to CO 2 At 0.2×10 -2 ×a~2×10 -2 ×a (0.2-2% by mass when expressed in other ratios) range, the amount of sulfur introduced into the glass raw material in the form of sulfate is converted into SO 3 At 0.07×10 -2 ×a~0.5×10 -2 ×a (0.07 to 0.5% by mass when expressed in other ratios), the number density of bubbles in the optical glass is contro...

Embodiment 2

[0678] Next, in order to obtain the glass of the composition shown in Table 4 and Tables 5-1 to 5-2, boric acid, oxides, carbonates, and sulfates were weighed, and glass raw materials were prepared. As the carbonate, lanthanum carbonate, zinc carbonate, and barium carbonate were used, and as the sulfate, zinc sulfate, barium sulfate, and the like were used. In addition, neither As nor nitrate was introduced into the glass raw material.

[0679] The amount of carbon contained in the glass material (external ratio) is converted to CO 2 , SO 3 The amount of is shown in Table 4 and Tables 5-1 to 5-2.

[0680] The prepared glass raw material is put into a platinum crucible, heated and stirred at 1100 to 1350°C while being melted, and the molten glass is poured into a casting mold for forming. Next, the formed glass is pulverized into granules to form a glass flake raw material.

[0681] In this way, for each optical glass, a glass flake raw material with a refractive index slightly lowe...

Embodiment 3

[0686] Various optical glasses were obtained by the method described in Example 1. The clarified and homogenized molten glass was prepared, flowed out of the tube at a fixed speed, and poured into a casting mold to form plate glass or round rod glass.

[0687] After annealing the obtained plate-shaped glass or round rod-shaped glass, it is cut and divided into glass pieces called slices, and a plurality of glass blocks are polished by a barrel.

[0688] Next, boron nitride, which is a powdered mold release agent, was uniformly coated on the entire surface of the glass block, heated in a heating furnace to soften it, and a compression molding mold consisting of an upper mold, a lower mold, and a body mold was used to It is formed into various lens blanks. The lens blank taken out from the press molding mold is annealed to reduce internal strain, and the refractive index is fine-tuned to make the refractive index of the glass consistent with the desired value.

[0689] The annealed le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com