Composite Separators for Li-ion Batteries

A technology of lithium-ion batteries and composite diaphragms, which is applied to battery components, circuits, electrical components, etc., can solve problems such as low production performance and usability, low membrane rupture temperature, and poor heat resistance, and prevent rapid rupture and heat shrinkage, increase the rupture temperature, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] refer to figure 1 1. The polytetrafluoroethylene composite diaphragm for lithium ion battery of the invention comprises a diaphragm, and the diaphragm is formed by an upper polypropylene microporous membrane 1 and a lower polypropylene microporous membrane 2, and the upper polypropylene microporous membrane is A polytetrafluoroethylene microporous membrane 5 is also arranged between 1 and the lower polypropylene microporous membrane 2, and the polytetrafluoroethylene composite separator for lithium ion batteries is formed by layer-by-layer stacking.

Embodiment 2

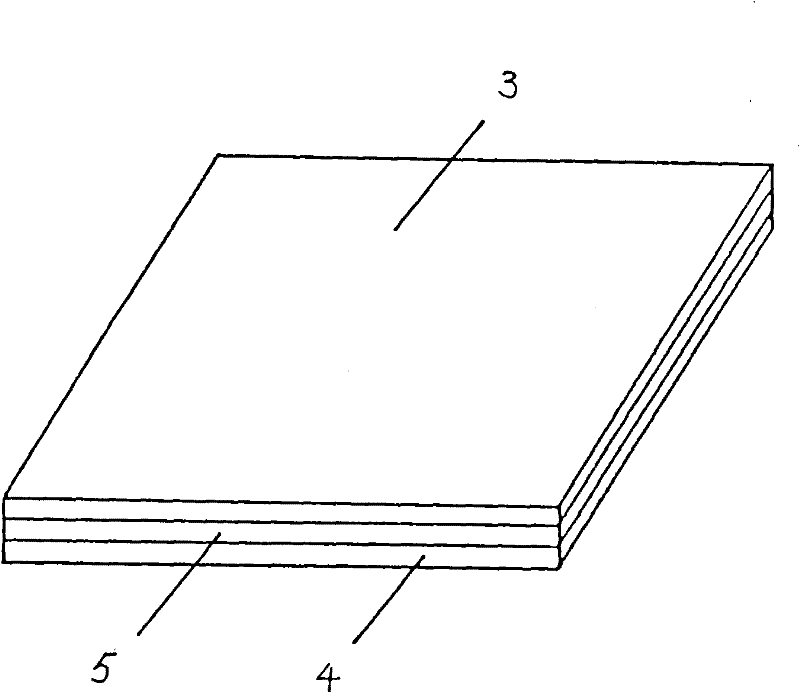

[0024] refer to figure 2 1. The polytetrafluoroethylene composite diaphragm for lithium ion battery of the invention comprises a diaphragm, and the diaphragm is formed by an upper polyethylene microporous membrane 3 and a lower polyethylene microporous membrane 4, and the upper polyethylene microporous membrane is There is also a polytetrafluoroethylene microporous membrane 5 between 3 and the lower polyethylene microporous membrane 4, and the polytetrafluoroethylene composite separator for lithium ion batteries is formed by layer-by-layer stacking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com