Arrangement device for double-layer swirl burn-off air of garbage incinerator

A technology of waste incinerator and burnout air, which is applied in incinerators, combustion methods, combustion types, etc., can solve problems such as affecting the flow structure of flue gas, and achieve simple and easy technical means, improve burnout rate, and increase residence time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

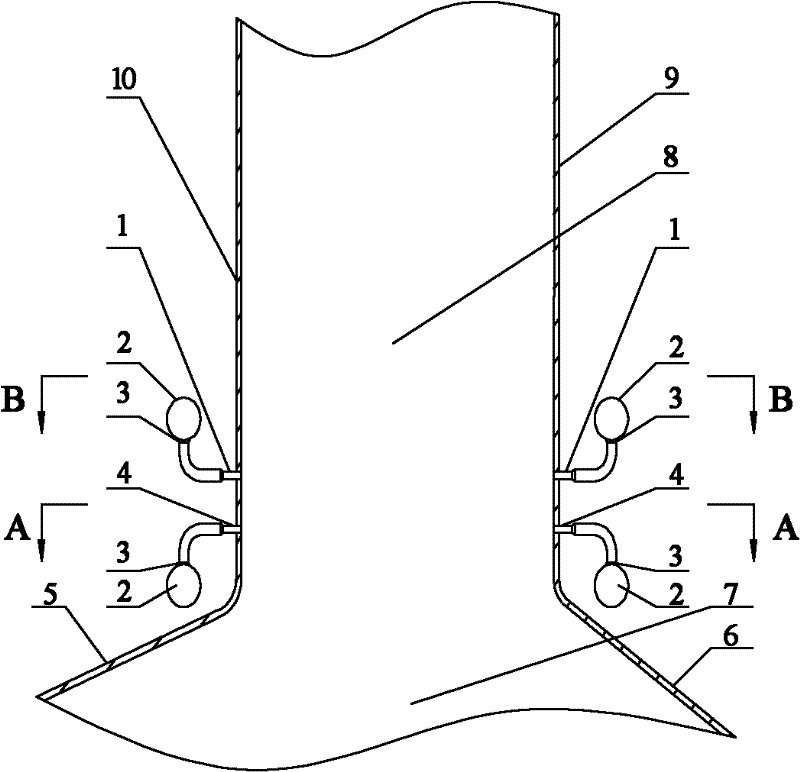

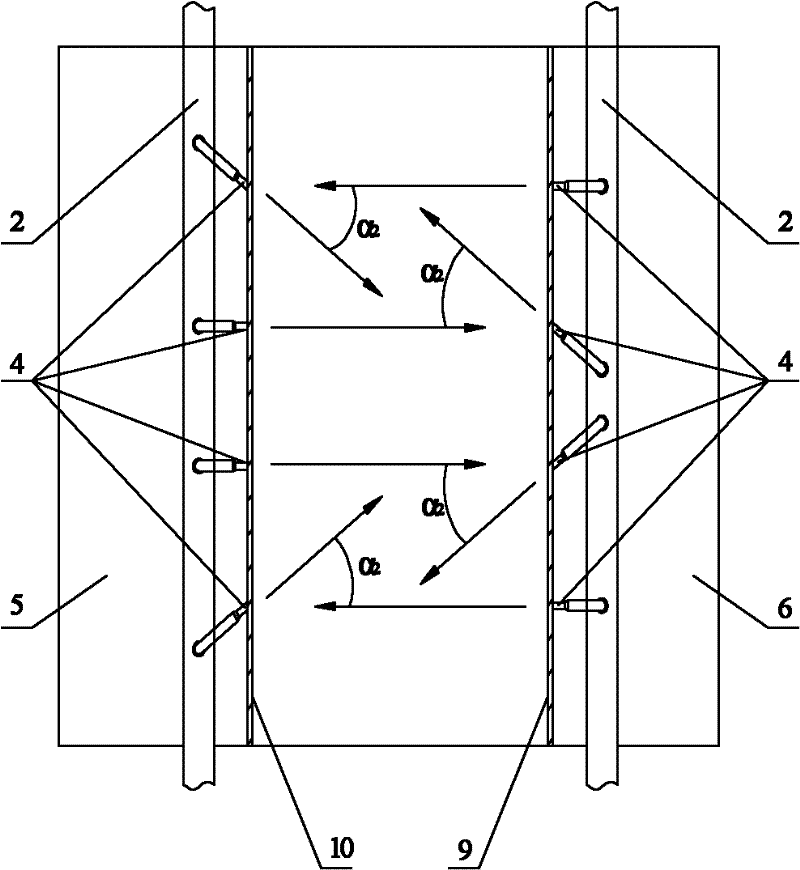

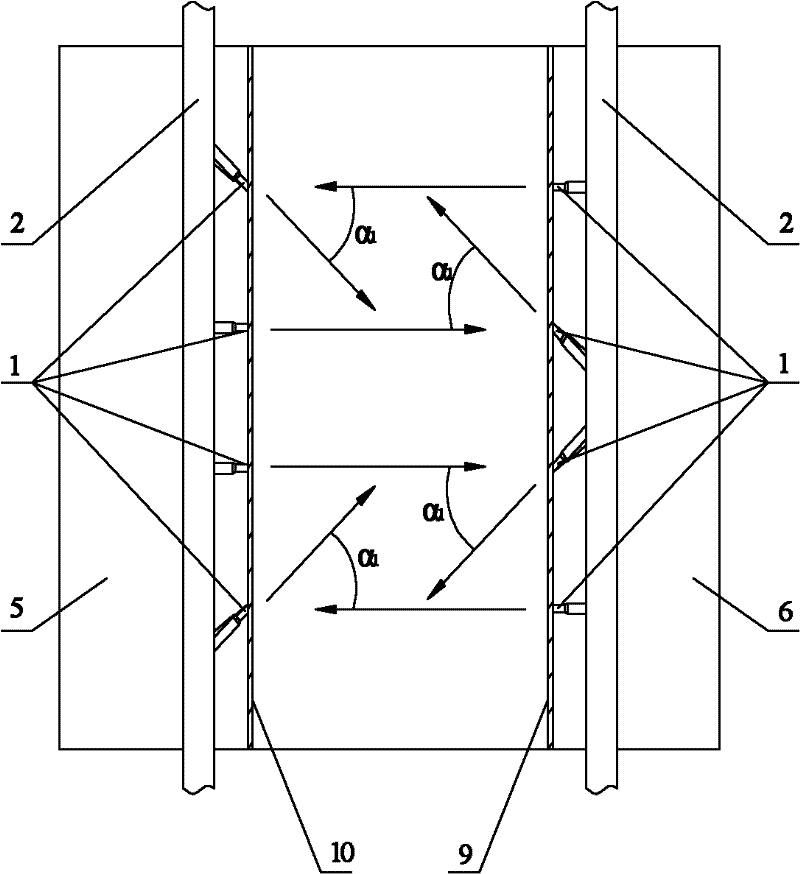

[0024] like figure 1 As shown, the waste incinerator double-layer swirl burnout wind arrangement device of the present invention includes a combustion chamber 7 and a furnace chamber 8 of the garbage incinerator, and the furnace chamber 8 includes a front wall 10 and a rear wall 9. 7 and the junction of the furnace 8, that is, the bottom positions of the front wall 10 and the rear wall 9 are arranged with two layers of exhausted air nozzles 1, 4, that is, the front arch 5 and the rear arch 6 of the combustion chamber 7 and the furnace 8 are arranged. junction transition zone.

[0025] The inlets of the above-mentioned exhausted air nozzles of each layer are correspondingly communicated with respective exhausted air ducts 2, and the exhausted air nozzles are communicated with the furnace chamber 8. damper 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com