Method and device for controlling an internal combustion engine

A technology for internal combustion engines and equipment, applied to mechanical equipment, internal combustion piston engines, electrical control, etc., can solve the problems of wasting gas potential energy, etc., and achieve the effects of low emissions, short and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

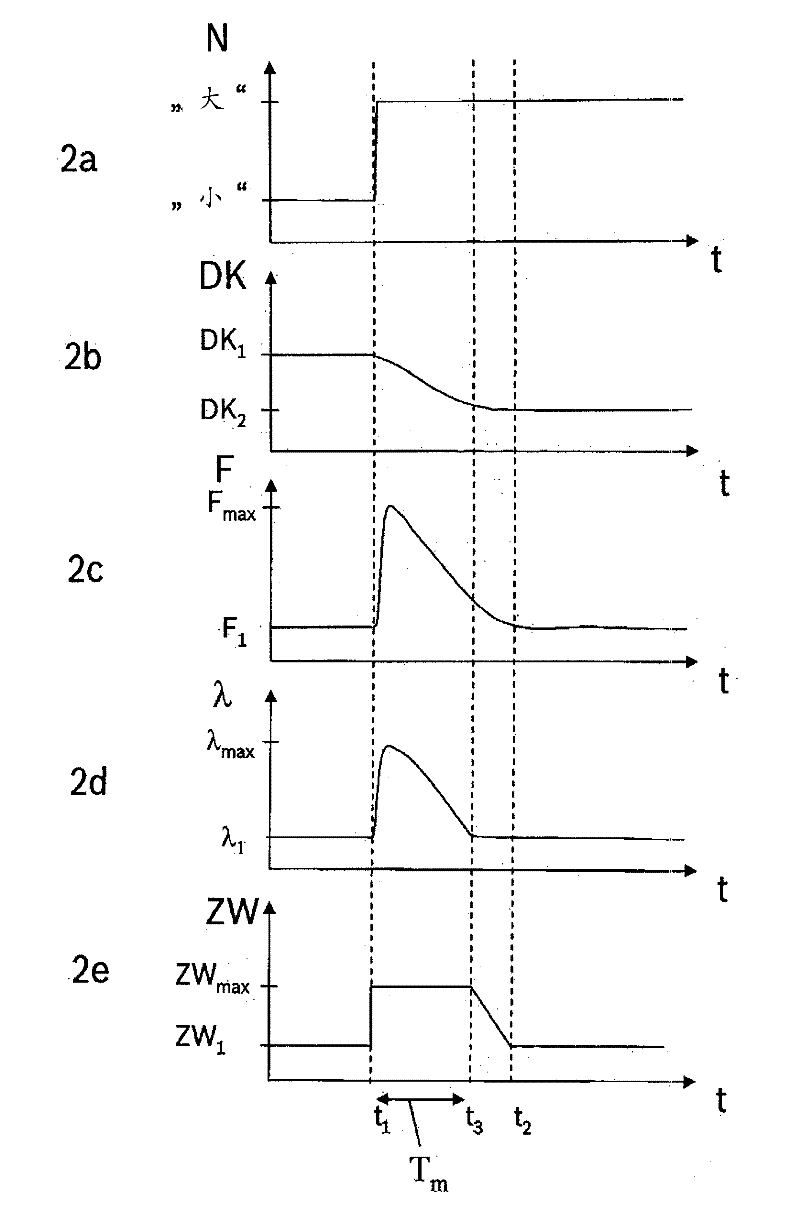

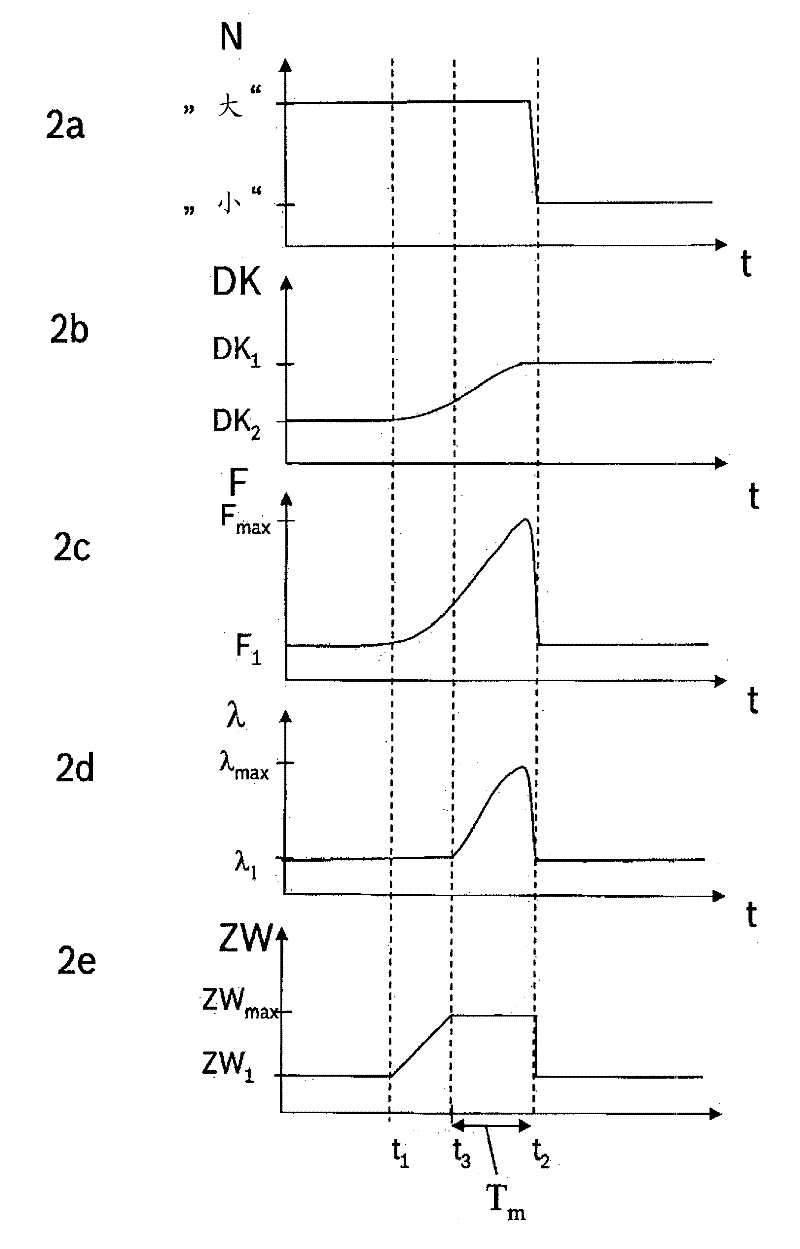

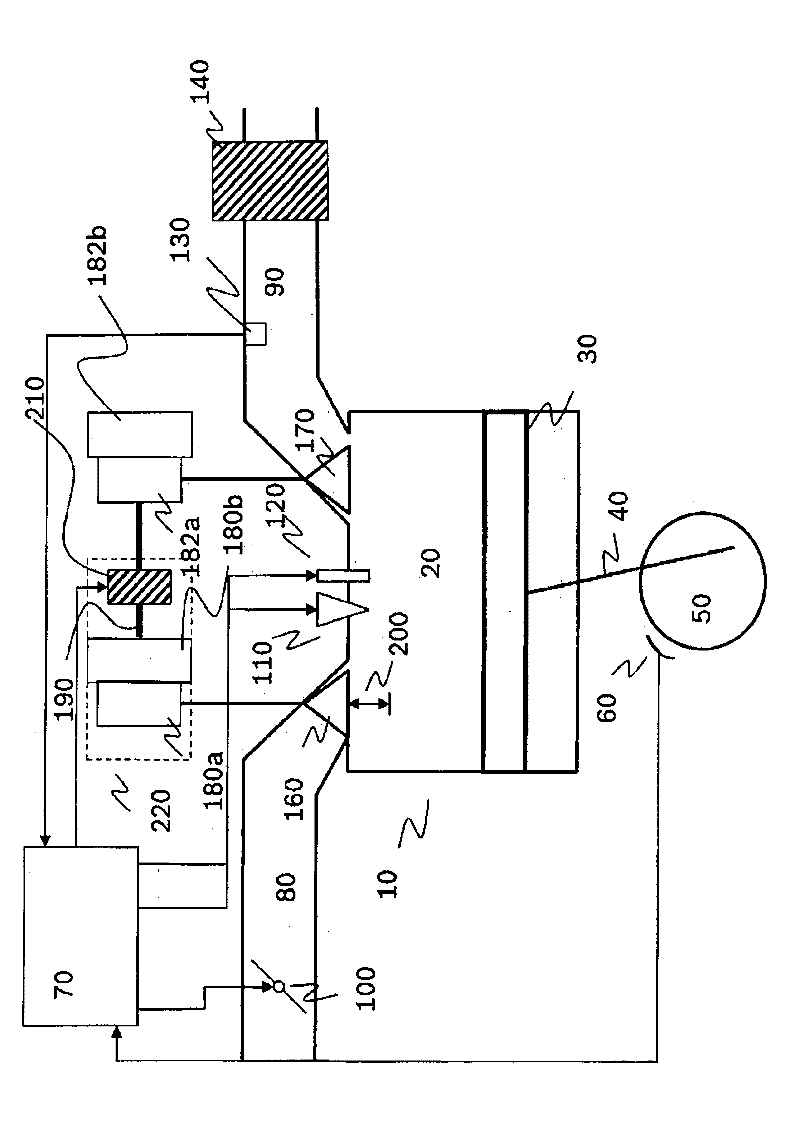

[0019] figure 1 A cylinder 10 of an internal combustion engine is shown with a combustion chamber 20 and a piston 30 connected to a crankshaft 50 by means of a connecting rod 40 . Crankshaft angle sensor 60 senses the angular position of rotating crankshaft 50 . Information about the angular position of crankshaft 50 is relayed to controller 70 .

[0020] During the downward movement of the piston 30 , air to be combusted is drawn into the combustion chamber 20 via an intake duct 80 in a known manner. As the piston 30 moves upward, the combusted air is forced out of the combustion chamber 20 through the exhaust pipe 90 . The amount of air inhaled through the intake pipe 80 is adjusted through the air charge changing device, which is a throttle valve 100 in this embodiment, and the position of the throttle valve is determined by the controller 70 .

[0021] Fuel is injected into the air sucked in from the intake pipe 80 via the injection valve 110 provided directly in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com