Auxiliary composition and application thereof for low-temperature one-bath scouring and bleaching process of cotton textiles

A technology of cotton textiles and compositions, applied in the field of textile printing and dyeing, which can solve problems such as low solubility, high use cost, and fiber strength damage, and achieve the effects of reducing heating and cooling time, saving processing time, and reducing strength loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0065]1. Preparation of low-temperature activated catalyst sustained-release capsules: in order to meet the needs of the bleaching process, the present invention selects a mixture of iron disodium edetate and ammonium metavanadate with a weight ratio of 2:1 as the catalyst, and uses sodium alginate, chitosan Sugar acts as a microcapsule membrane. The specific preparation process is to put the mixed catalyst weighing 25% of the total solids through an 80-mesh sieve into a reaction vessel, add 1.5% sodium alginate aqueous solution, oscillate and mix on a vortex suspender, and dissolve the obtained suspension Add it dropwise to a 2% acetic acid solution containing 0.5% chitosan (containing 1.5% calcium chloride) that is stirred at a slow speed. After the addition is completed, continue to stir for 5 minutes, and then use a pump to send it into a spray-dried atomizer. , the dispersion liquid is atomized into small droplets, and when the water in the droplets evaporates rapidly, a ...

Embodiment

[0070] Embodiment: the application of adjuvant composition

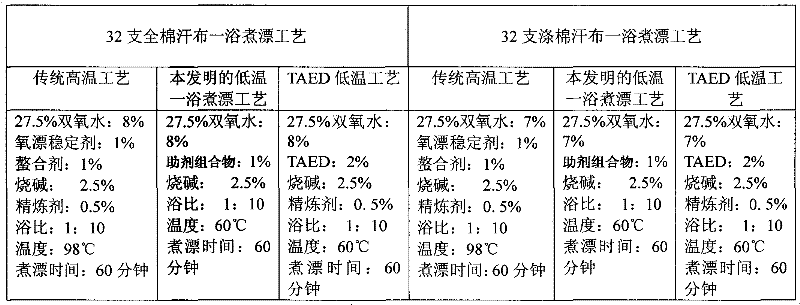

[0071] (1) The comparison between the traditional high-temperature cooking and bleaching process and the low-temperature one-bath boiling and bleaching process of the present invention, see Table 2 for details.

[0072] Table 2

[0073]

[0074] The above traditional high-temperature process and the low-temperature process of TAED activator all adopt reagents commonly used in this field, wherein the oxygen bleaching stabilizer is HK, the chelating agent is HK-101, and the refining agent is HK-1031 (Ningbo Yinzhou Huake Textile Auxiliary Co., Ltd. Auxiliary products produced by the company). The adjuvant composition is the adjuvant composition provided by the present invention.

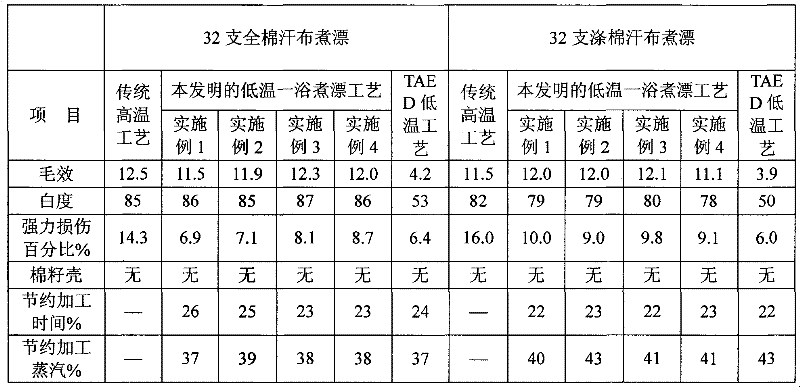

[0075] (2) Application effect comparison

[0076] In this embodiment, the auxiliary agent composition prepared in Examples 1-4 is selected and applied to the low-temperature one-bath decoction and bleaching process provided by the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com