A kind of grape vinegar brewed with yeast and preparation method thereof

The technology of grape vinegar and yeast is applied in the food field to achieve the effects of high product quality, good sanitary conditions and low production labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Specific steps are as follows:

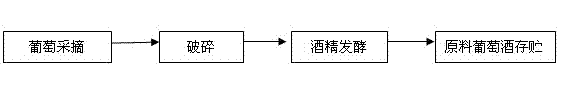

[0029] 1) Preparation of raw wine: grape harvesting, crushing, alcoholic fermentation, winemaking storage (grape harvesting, alcoholic fermentation, etc. are carried out according to the production process of dry red wine. Long, stored first wine can be used for year-round processing);

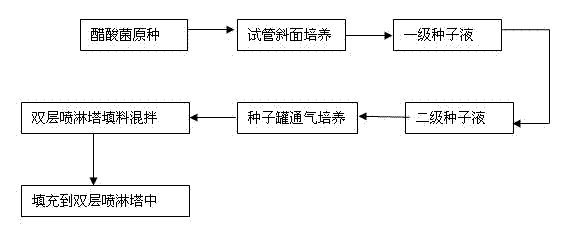

[0030] 2) Preparation of acetic acid bacteria seed solution: transfer Pichia pastoris to sterile water and dilute to 10ˉ 4 ~10ˉ 5 Times, preparation plate separation medium composition (percentage by weight): glucose 10%, peptone 2%, yeast extract 1%, agar 1.5%, add the wine to be brewed to 100%; add 4% alcohol to the medium under sterile conditions , will be diluted to 10ˉ 4 ~10ˉ 5 Divide 1 mL of double concentration of acetic acid bacteria into 0.1 mL and drop it on the culture medium, send it to a 30°C incubator for cultivation, after 5 days of cultivation, acetic acid bacteria colonies appear, select the single colony with the largest diameter, ...

Embodiment 2

[0037] The difference with embodiment 1 is:

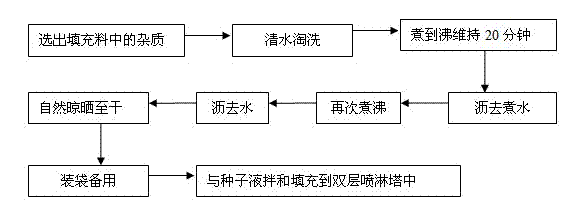

[0038] 3) Preparation of double-layer spray tower packing: the packing can be used: crushed grape branches, rough wood tips, wood shavings, bagasse, etc., after washing and boiling for 20 minutes, filter off the boiling water, boil again, filter off and boil Water, after drying, add 10% volume percentage 2) The seed liquid obtained in step 2 is mixed with the filler (the base of the percentage of seed liquid is the total capacity of the filler), and then filled into the double-layer spray tower;

[0039] In the present invention, the inner wall of the cement pool structure can also be used for anti-acid treatment, and the double-layer spray tower 12 is moved to the top of the fermentation tank 18, so that the pump 17 can be omitted, and the wine mash can flow into the fermentation tank 18. In practice The 30 air compressor can not be used, but it will prolong the fermentation time. It can be determined whether to use the 30 air com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com