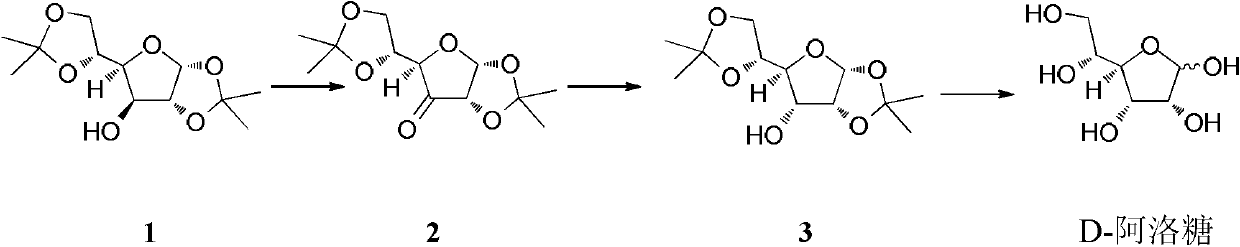

A method for preparing d-allose by reducing ketose by catalytic hydrogenation

A kind of technology of allose and catalyst, applied in the field of preparing D-allose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, preparation D-allose

[0035] A mixed system containing 10g Raney Ni (Raney nickel), 200mL methanol and 10g 1,2:5,6-O-dipropylidene-3-deoxy-3-oxo-α-D-glucose 2 was dissolved in 30atm hydrogen React under pressure for 72 hours at a reaction temperature of 28-35°C. The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection found that it contained 1,2:5,6-O-dipropylidene-α-D-glucose 1 (content 18%) and 1,2:5,6-O-dipropylidene-α-D-A Lulose 3 (content 82%). The conversion efficiency was 82%. The "transformation efficiency" in the present invention refers to the 1,2:5,6-O-dipropylidene-α-D-allose 3 produced relative to the 1,2:5,6-O- Ratio of bispropylidene-3-deoxy-3-oxo-α-D-glucose 2.

[0036] The NMR characterization of 1,2:5,6-O-dipropylidene-α-D-allose 3 is as follows: 1 H-NMR (300MHz, CDCl 3 ), δ (ppm), 5.82 (1H, d, J = 3.8Hz), 4.62 (1H, dd, J = 5.0Hz, 4.1Hz), 4.30 (1H, ...

Embodiment 2

[0038] Embodiment 2, preparation D-allose

[0039] A mixed system containing 10mg Pd / C (10%), 20mL ethanol and 100mg 1,2:5,6-O-dipropylidene-3-deoxy-3-oxo-α-D-glucose 2 was dissolved in 50atm hydrogen React under pressure for 72 hours, and the reaction temperature is 28-35°C. The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection revealed that it contained unreacted ketose 2 (content 86%) and 1,2:5,6-O-dipropylidene-α-D-allose 3 (content 14%). The conversion efficiency was 100%. The product was recrystallized in a mixed solvent of ethyl acetate / petroleum ether, and then separated by column chromatography (mobile phase: ethyl acetate / petroleum ether=1 / 3) to obtain 1,2:5,6-O-bispropylidene -α-D-Allose 3.

[0040] The resulting reduction product 1,2: 5,6-O-dipropylidene-α-D-allose 3 was reacted at 90°C for 12 hours in the presence of an acidic resin in the presence of a macroporous strongly a...

Embodiment 3

[0041] Embodiment 3, preparation D-allose

[0042] 10mg contains Pd(OH) 2 , 10mL of methanol and 20mg of 1,2:5,6-O-dipropylidene-3-deoxy-3-oxo-α-D-glucose 2 was reacted under 50atm hydrogen pressure for 48 hours, and the reaction temperature was 30- 40°C. The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection found that it contained 1,2:5,6-O-dipropylidene-α-D-glucose 1 (content 6%), unreacted ketose 2 (content 66%) and 1,2:5,6 -O-dipropylidene-α-D-allose 3 (content 28%). The conversion efficiency was 81%. The product was recrystallized in ethyl acetate / petroleum ether mixed solvent, and then separated by column chromatography (mobile phase: ethyl acetate / petroleum ether=1 / 3, v / v) to obtain 1,2:5,6-O - Dipropylidene-α-D-allose 3.

[0043] The resulting reduction product 1,2: 5,6-O-dipropylidene-α-D-allose 3 was reacted at 90°C for 12 hours in the presence of an acidic resin in the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com