Color-coating line wringing roller unpowered deviation correction device

A technology of deviation correction device and water squeezing roller, which is applied in the field of deviation correction device, can solve problems such as quality problems, affecting the normal operation of the production line, and the inability to guide the steel plate to run vertically and straightly, so as to achieve the effect of improving the pass rate and good water squeezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

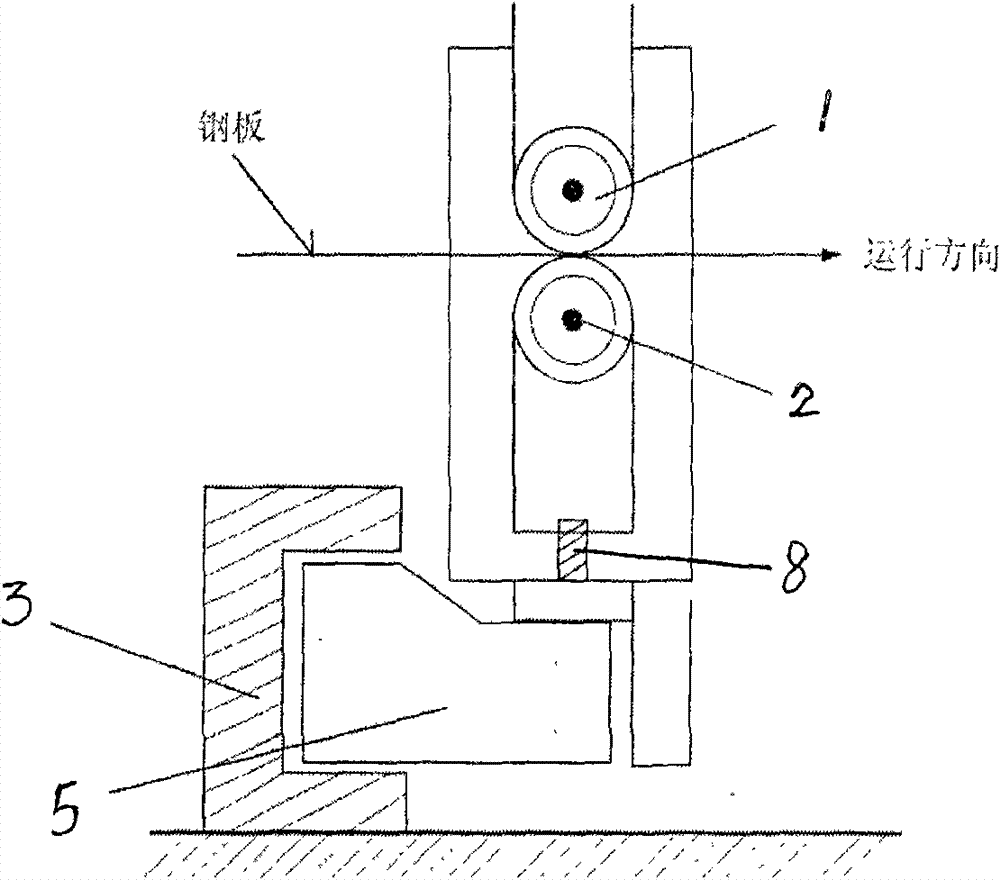

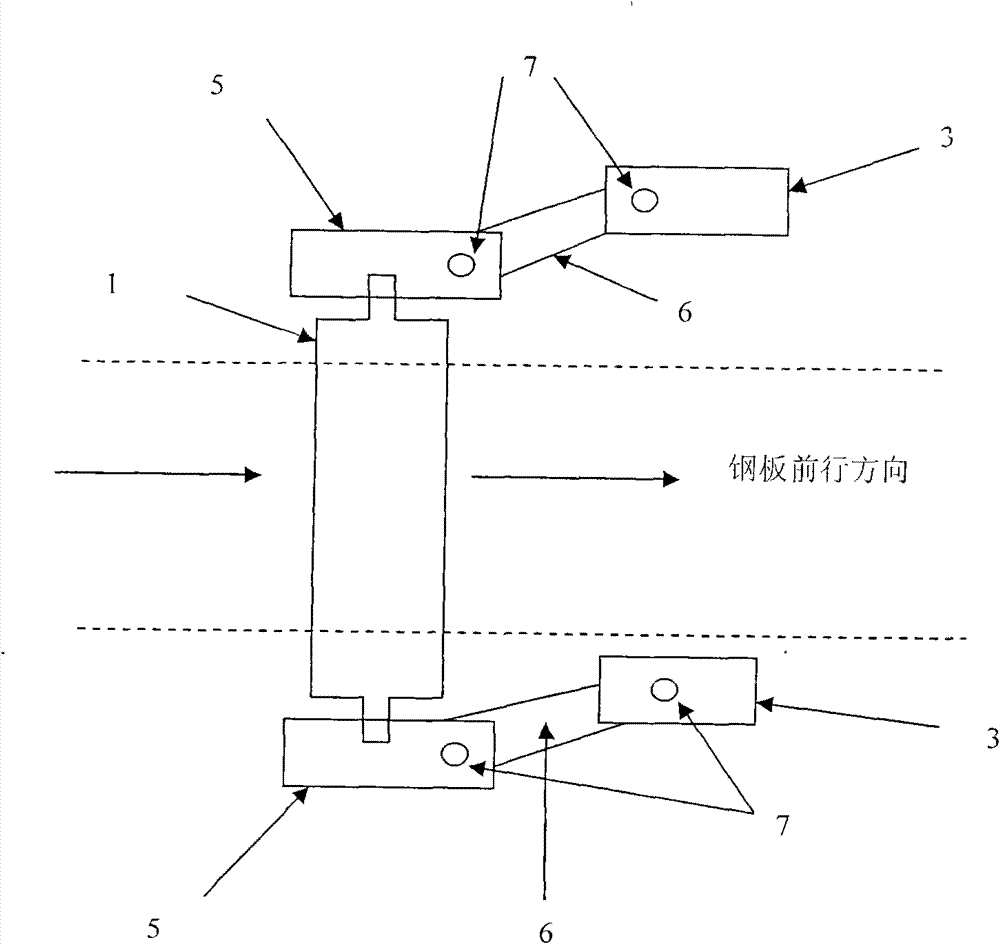

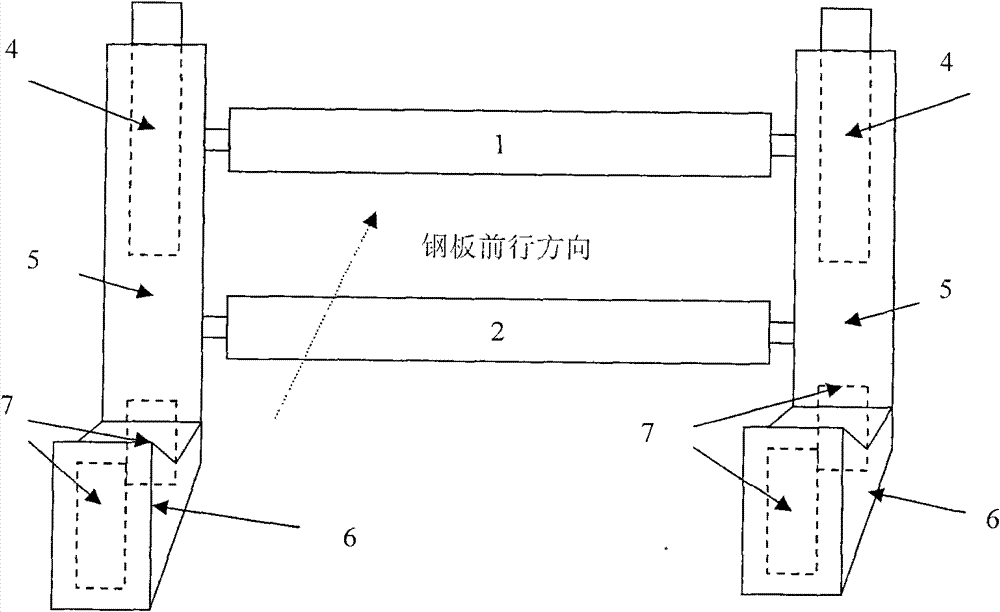

[0011] Example 1, the non-powered correction device for the squeeze roller of the color coating line, including the upper squeeze roller 1, the lower squeeze roller 2, and the fixed bracket 3, the upper squeeze roller 1 is connected to the cylinder 4, and the lower squeeze roller 2 is a fixed roller, The upper and lower squeeze rollers are fixed by the squeeze roller support arms 5 at both ends, and the two squeeze roller support arms 5 are connected to the fixed bracket 3 by the movable swing arm 6 and the movable shaft 7 respectively.

Embodiment 2

[0012] Embodiment 2, with reference to Embodiment 1, a threaded rod 8 is provided at the joint between the lower squeezing roller 2 and the supporting arm 5 of the squeezing roller, and the swing of the movable swing arm 6 connected with the supporting arm 5 of the squeezing roller and the fixed bracket 3 The amplitude is designed to be ±30°.

[0013] After the anti-rust treatment on the surface of the steel plate is removed, it enters the working link of the water squeezing roller. Due to the installation of the deviation correction device of the present invention, the working pressure of the water squeezing upper roller can be designed at 0.4Mpa-0.6Mpa, and it can be adjusted according to the amount of water on the steel plate. The pressure of the squeeze roller on the steel plate, under this working pressure, can achieve the purpose of completely squeezing the water stains on the surface of the steel plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com