Current-limiting circuit breaker high-speed contact drive mechanism

A driving mechanism and circuit breaker technology, applied in the protection switch operation/release mechanism, etc., can solve the problems of low efficiency of electromagnetic repulsion mechanism, short mechanical life of the mechanism, large initial energy, etc., to ensure the current limiting breaking effect and prolong the mechanical life. , the effect of improving acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

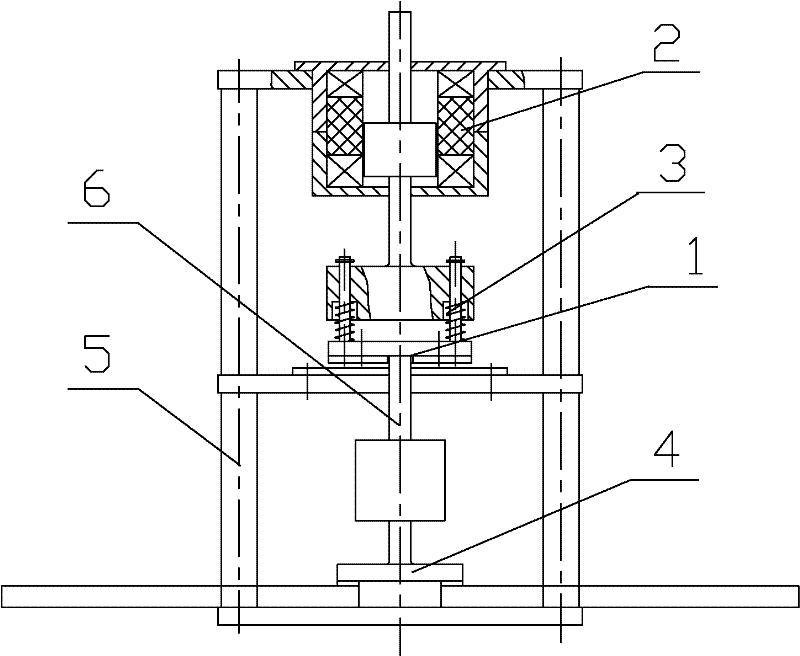

[0021] Such as figure 1 As shown, the high-speed contact drive mechanism of the current-limiting circuit breaker of the present invention includes a frame 5, and the electromagnetic repulsion mechanism 1, the spring connection mechanism 3, and the permanent magnet mechanism 2 are arranged in the frame 5 sequentially, wherein the frame 5 includes four The vertical column, the top, middle and bottom of the column are fixed with bolts to install the horizontal frame respectively, the permanent magnet mechanism 2 is fixed and suspended under the horizontal frame at the top of the column by bolts, and the electromagnetic repulsion mechanism 1 is fixed and installed above the horizontal frame in the middle of the column with bolts , the spring connection mechanism 3 is fixedly installed above the electromagnetic repulsion mechanism 1 .

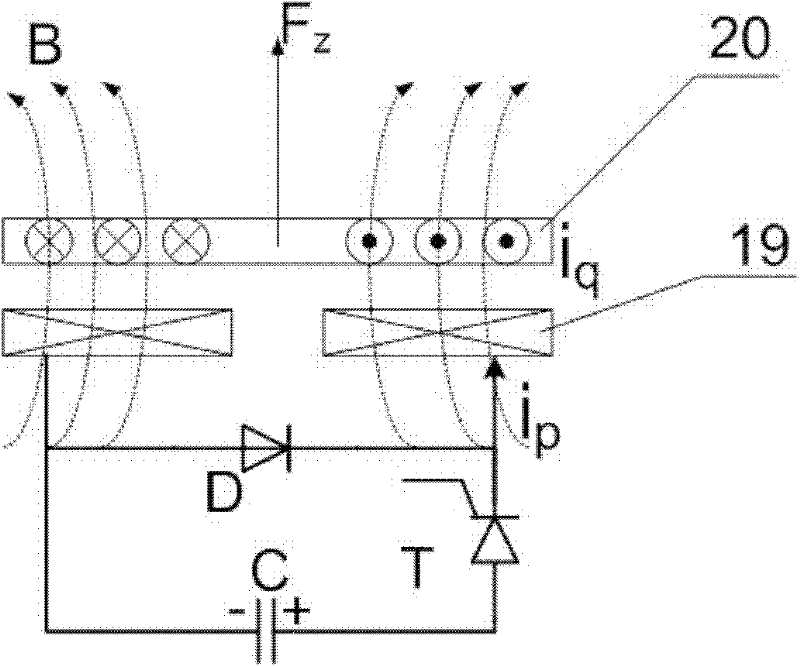

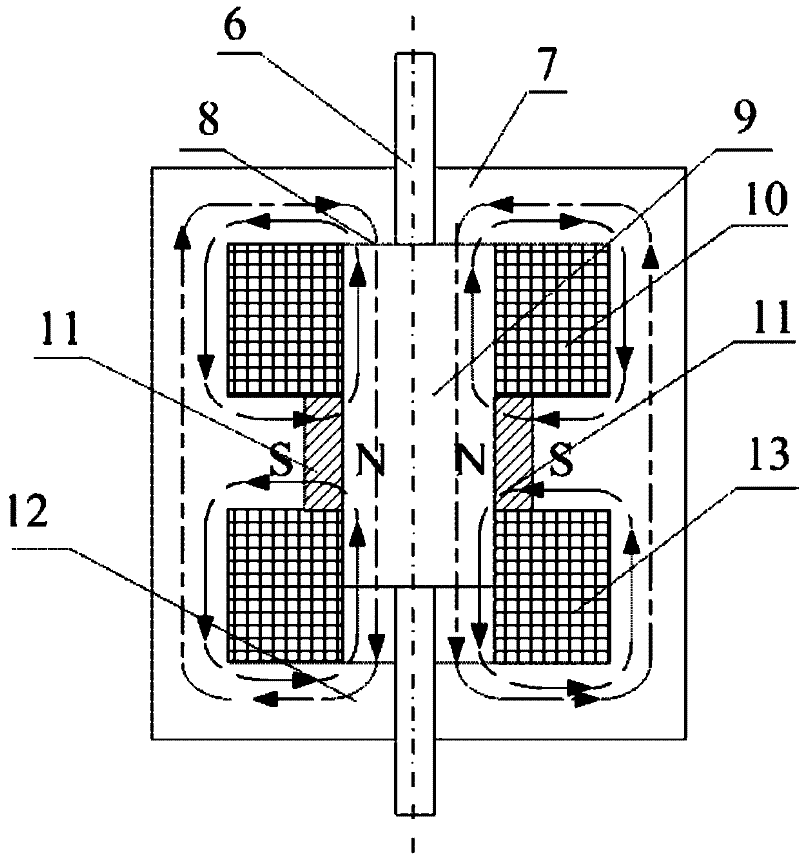

[0022] The electromagnetic re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com