An Alloy Electrode Electrochemical Sensor for Detecting Trace Heavy Metals

A technology of trace heavy metals and alloy electrodes, applied in the direction of material electrochemical variables, etc., can solve the problems of easy oxidation in the detection process, complex manufacturing process of bismuth rod electrodes and bismuth film electrode sensors, limited applications, etc., to achieve good electrochemical performance , Easy to make, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Sensors using tin-bismuth alloy disc electrode as working electrode:

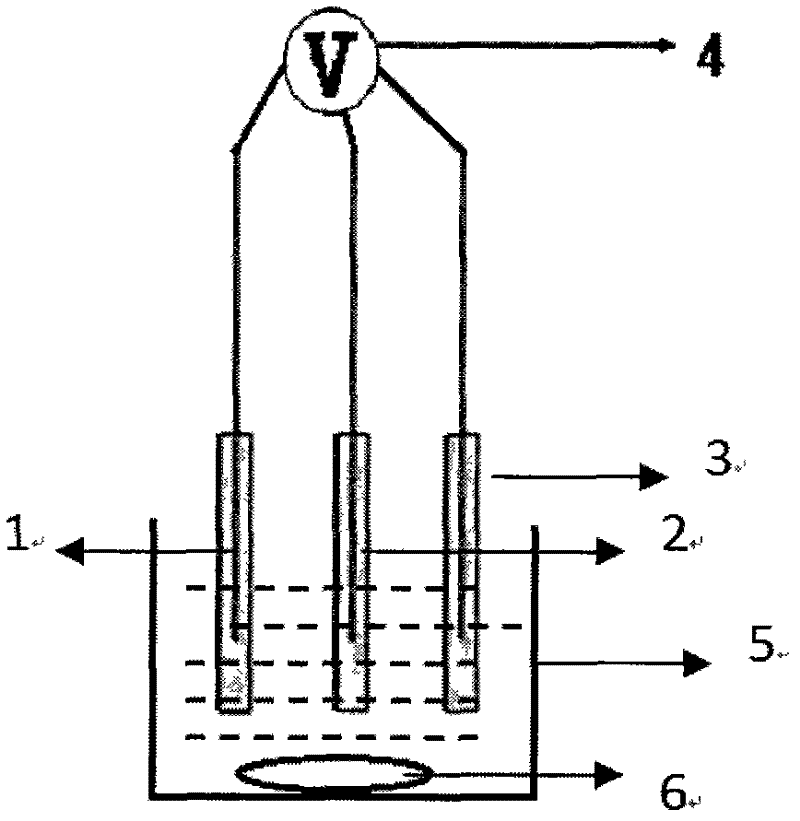

[0026] Such as figure 1 with 2 The sensor shown: the working electrode 1, the reference electrode 2 and the auxiliary electrode 3 are connected to the control potentiometer 4 by wires respectively; the working electrode 1, the reference electrode 2 and the auxiliary electrode 3 are inserted into the detection cell 5 containing the detection liquid, The detection cell 5 is provided with a magnetic stirrer 6 with a stirring effect, and the bottom of the detection cell is equipped with a magnetic stirrer to rotate the magnetic stirrer. The platinum electrode is used as the auxiliary electrode, the saturated calomel electrode is the reference electrode, and the potentiometer is controlled to measure the current response value.

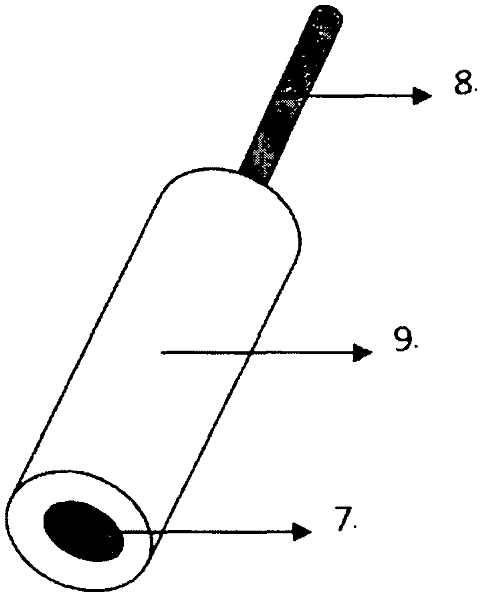

[0027] The tin-bismuth alloy disc electrode has a structure of a tin-bismuth alloy wire 7 that is sealed with an inert insulating sealing material 9 on the outer surface, wherein the ...

Embodiment 2

[0029] The difference from Example 1 is that the working electrode is:

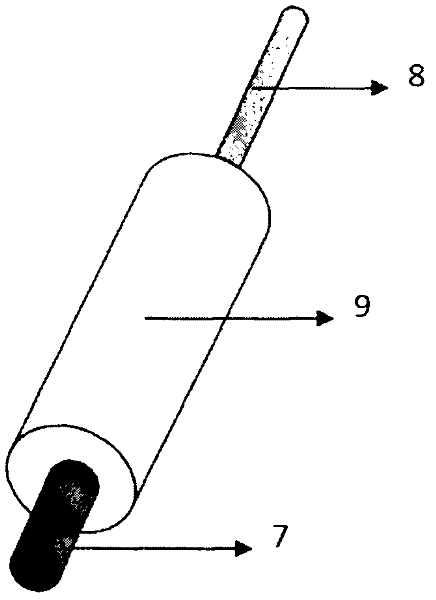

[0030] The tin-bismuth alloy column electrode is a structure of a tin-bismuth alloy wire 7 sealed with a PTFE sleeve 9 on the outer surface. One end of the tin-bismuth alloy wire 7 passes through one end of the PTFE sleeve 9, and the other end is inert to the insert. The lead 8 connection in the insulating sealing material (see image 3 ).

[0031] PTFE sleeve can be replaced by Ke1-F, AB rubber sleeve or glass sleeve. The reference electrode is a silver / silver chloride electrode, and the auxiliary electrode is a glassy carbon electrode.

Embodiment 3

[0033] The difference from Example 1 is that the working electrode is:

[0034] The working electrode 1 is a tin-bismuth alloy printed electrode. The manufacturing method is specifically to use a 6mm×5cm polyvinyl chloride material as the electrode substrate 10, clean and dry it, and then use a screen printer to print a 3mm×4cm conductive silver glue layer 11 and The electrode lead 14 is dried under an infrared lamp for 24 hours; then the 4mm×4cm tin-bismuth alloy working electrode layer 12 is printed with tin-bismuth alloy paste and dried; finally, the electrode insulating layer 13 is printed with a light-solid insulating paste, and Set aside 4mm×4mm as the effective working area of the working electrode (see Figure 4 ), and finally cured with UV light.

[0035] The reference electrode is a printed silver / silver chloride electrode, and the auxiliary electrode is a printed silver electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com