Machine for testing tensile stress under high temperature & high pressure environments

A high-temperature, high-pressure, stress test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of inability to measure the corrosion resistance of materials, reduce economic losses, facilitate the test, and test The effect of reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

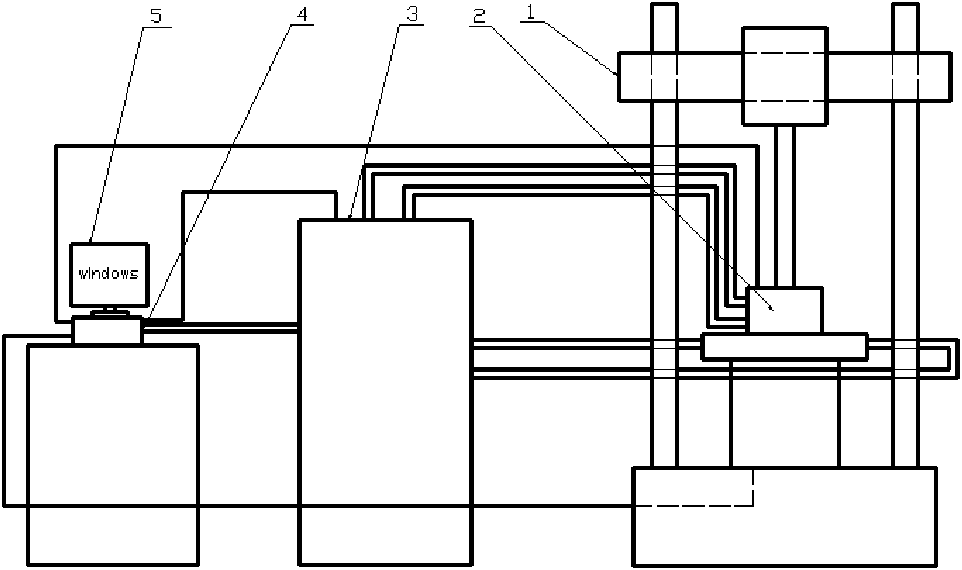

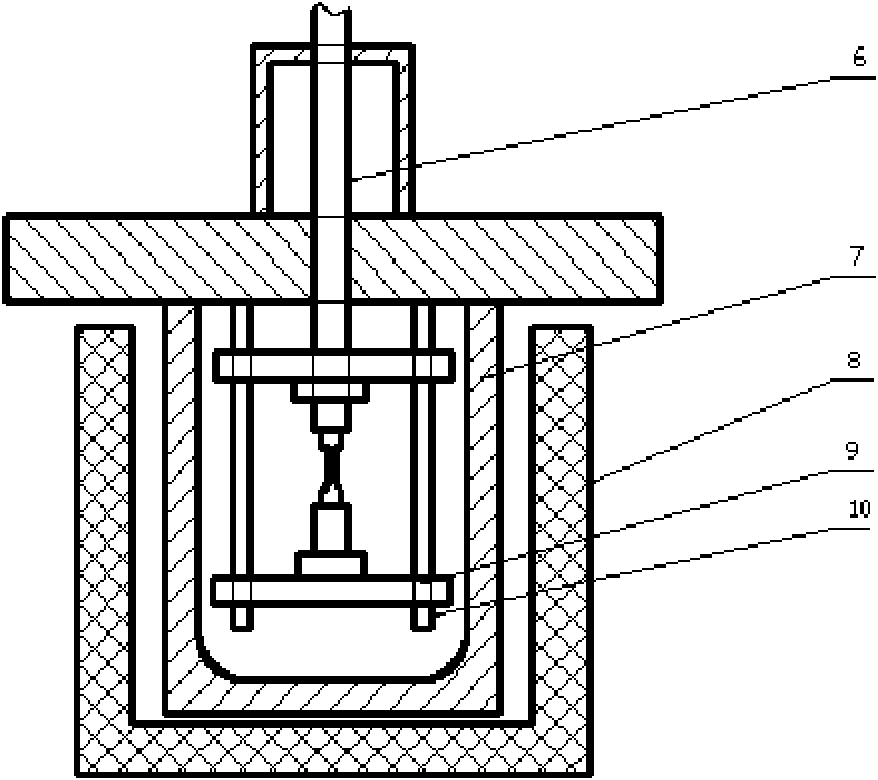

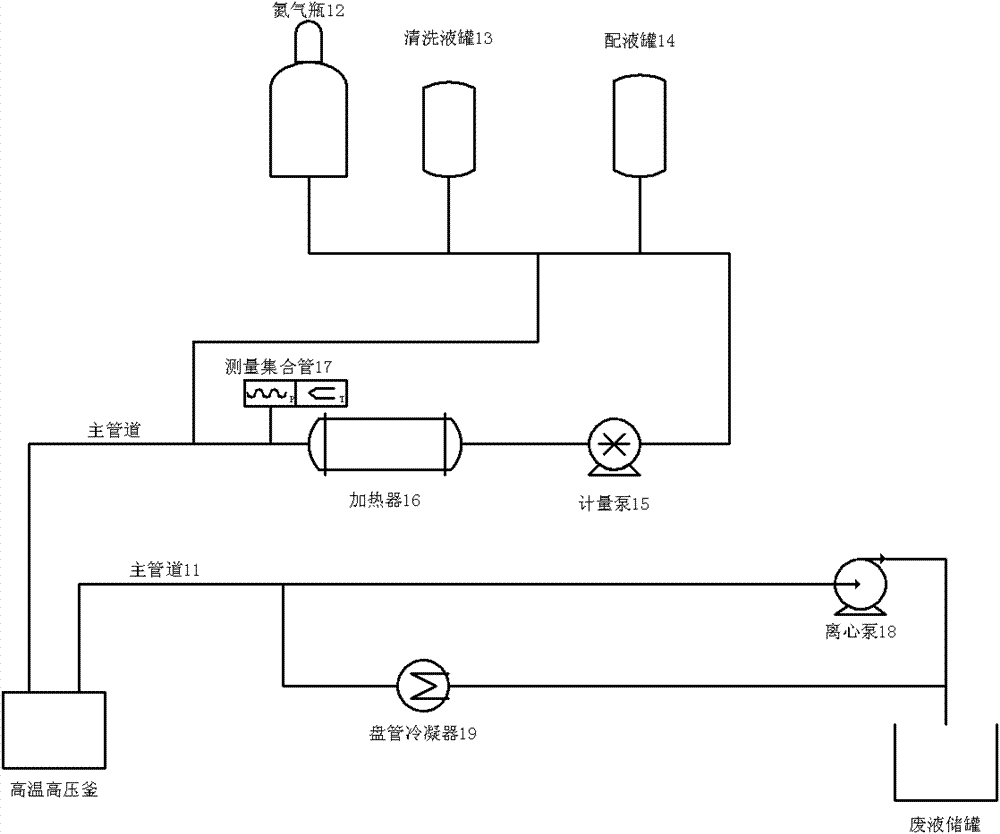

[0013] refer to figure 1 , 2 3. When it is necessary to measure the corrosion resistance of a material in a certain environment, start the auxiliary system 3 to clean and purge the entire device. After cleaning and purging, fix the test piece in the high-temperature autoclave 7 with a clamp 9, and cover the lid of the autoclave. Inject a certain amount of liquid with a corrosive medium into the high-temperature autoclave 7, raise the temperature and pressure of the high-temperature autoclave 7 through the heating furnace 8 in the high-temperature autoclave system 2, and control the temperature and pressure in the high-temperature autoclave 7 by the control system monitor. When the pressure and temperature required by the environment are reached, the control system 4 issues an instruction, and the heating furnace 8 stops heating and enters a heat preservation state. At this time, the stretching machine system starts to perform pulse stretching on the specimen. When the expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com