Power chamber sealing structure of dual-fuel locomotive

A dual-fuel locomotive, closed structure technology, applied in the direction of locomotives, railway transportation, climate sustainability, etc., to achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

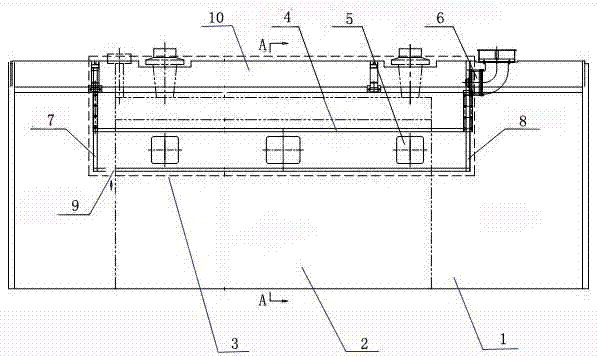

[0016] Such as figure 1 As shown, a closed structure of a dual-fuel locomotive power room includes a power room 1 and an engine 2 inside, the power room 1 seals the space above the engine 2 to form a closed room 3, and the top cover of the power room 1 is provided with a car body The ventilator 6 communicates with the interior of the closed chamber 3 , and the bottom of the closed chamber 3 is provided with an air inlet gap 10 , and the vehicle body ventilator 6 is arranged on the top cover of the front end of the power chamber 1 .

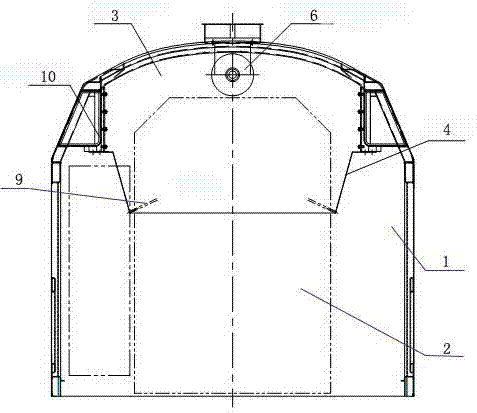

[0017] Such as image 3 As shown, the top of the power chamber 1 is provided with a fixed top cover 10, and the closed chamber 3 includes a rear end wall 7, a front end wall 8 and non-woven fabrics 4 on both sides, and the rear end wall 7, front end wall 8 and Non-woven fabric 4 is all detachable design, and the lower end is connected on the engine 2 with bolt, and the upper end is connected on the fixed top cover 10 with bolt.

[0018] An obser...

Embodiment 2

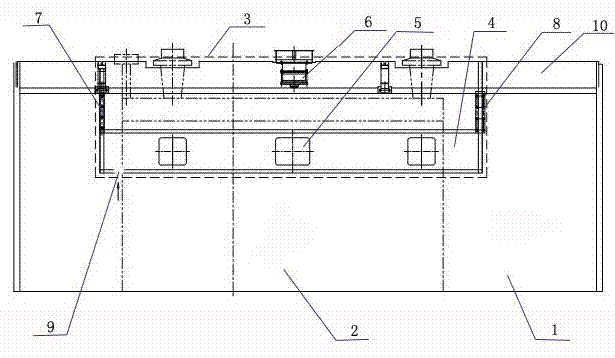

[0020] Such as figure 2 As shown, a closed structure of a dual-fuel locomotive power room includes a power room 1 and an engine 2 inside, the power room 1 seals the space above the engine 2 to form a closed room 3, and the top cover of the power room 1 is provided with a car body The ventilator 6 communicates with the interior of the closed chamber 3 , and the bottom of the closed chamber 3 is provided with an air inlet gap 9 , and the vehicle body ventilator 6 is arranged on the top cover of the middle part of the power chamber 1 .

[0021] Such as image 3 As shown, the top of the power chamber 1 is provided with a fixed top cover 10, and the closed chamber 3 includes a rear end wall 7, a front end wall 8 and non-woven fabrics 4 on both sides, and the rear end wall 7, front end wall 8 and Non-woven fabric 4 is all detachable design, and the lower end is connected on the engine 2 with bolt, and the upper end is connected on the fixed top cover 10 with bolt.

[0022] An obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com