Concrete conveying device and concrete processing technology adopting same

A conveying device and concrete technology, which is applied in the field of concrete processing technology and concrete conveying devices, can solve the problems of concrete initial setting and long concrete conveying time, and achieve the effects of saving resources, inhibiting shrinkage, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

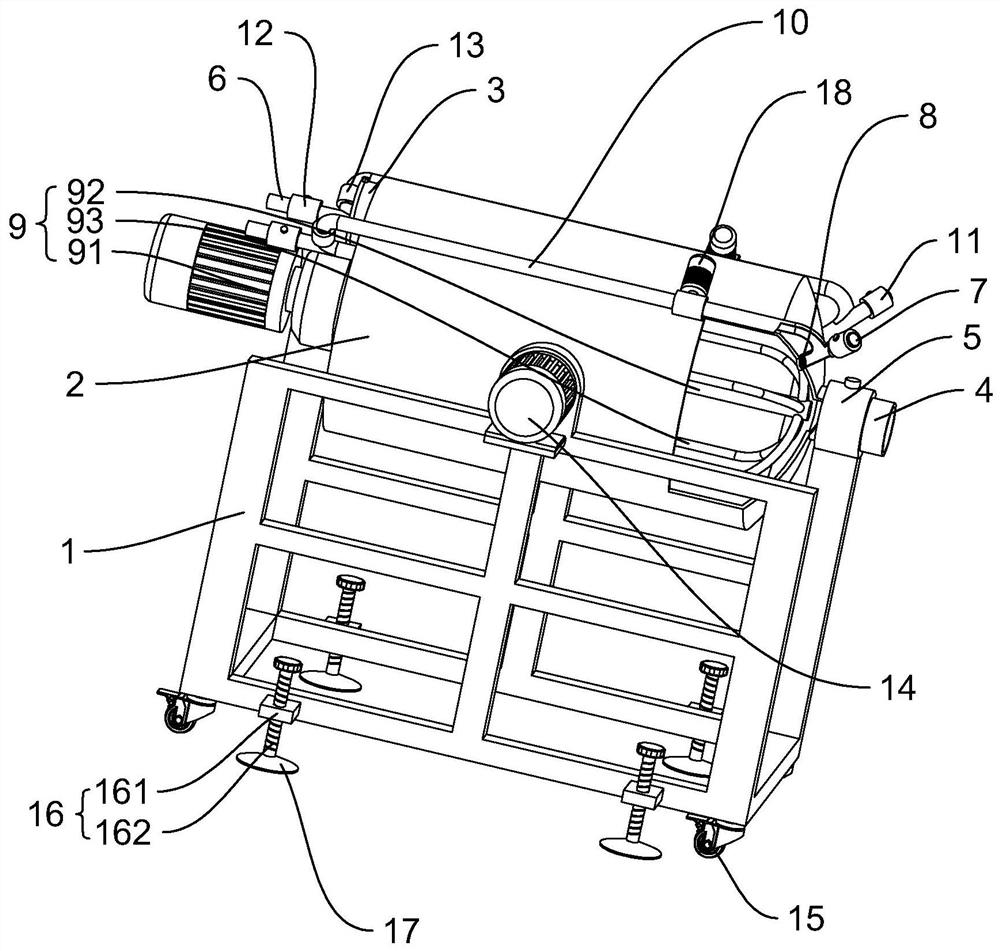

[0040] The following is attached figure 1 The application is described in further detail.

[0041] The embodiment of the present application discloses a concrete conveying device, referring to figure 1 , including a mounting frame 1 and a tank body 2 arranged on the mounting frame 1. One end of the tank body 2 is provided with a feed port 3, and a baffle plate is arranged at the feed port 3. One end of the baffle plate is hinged and the other end is fixed to the feed port by bolts. On 3, the baffle and the material inlet 3 are sealed. Loosen the bolt baffle to turn and open the material inlet 3. Tighten the bolt and the baffle is fixed to cover the material inlet 3, and the other end of the tank body 2 is fixed with a discharge pipe 4. A discharge valve 5 is provided on the discharge pipe 4, and the control of the discharge of the tank body 2 is realized by opening and closing the discharge valve 5. The tank body 2 is fixed with two water inlet pipes 6 at the end close to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com