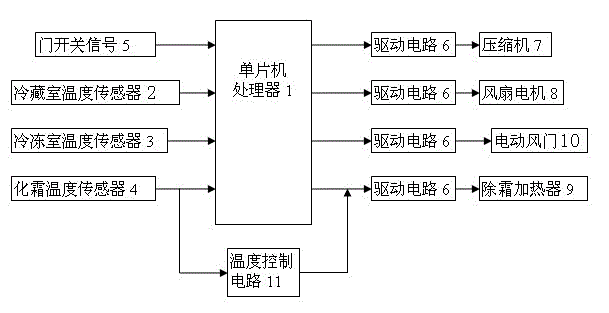

Control system and control method for frostless refrigerator heater

A control system and defrosting heater technology, applied in lighting and heating equipment, household refrigeration equipment, household appliances, etc., can solve the problems of high cost, difficult verification of single-chip software, long time, etc., and achieve the effect of avoiding high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

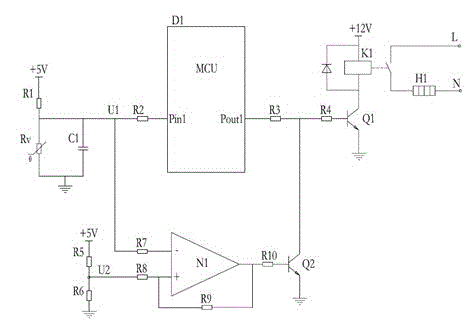

[0027] See attached figure 1 , in the input sampling circuit, the defrost temperature sensor RV is connected to the ground terminal. At this time, if the temperature rises, the resistance of RV becomes smaller, and the voltage at U1 decreases at this time. When the temperature of RV is higher than a certain limit temperature value T1 At this time, the voltage of U1 is lower than the U2 voltage value generated by the voltage division of R5 and R6, the operational amplifier N1 outputs a high level, and the transistor Q2 is turned on. At this time, even if the Pout1 port of the microcontroller outputs a high level, the transistor Q1 will also maintain cut off, the contact of relay K1 is disconnected, and the defrosting heater H1 is de-energized.

[0028] The range of T1 can be set to 10~50℃, and the voltage value of U2 can be changed by changing the resistance value of R5 or R6, so as to achieve the purpose of changing the limited temperature value T1.

Embodiment 2

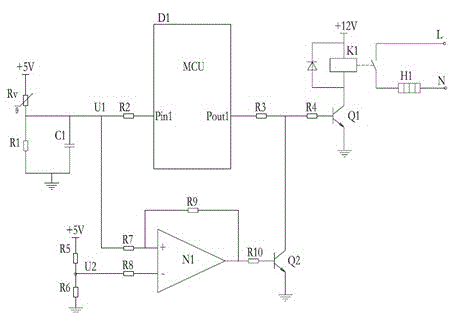

[0030] See attached figure 2 , In the input sampling circuit, the defrosting temperature sensor RV is connected to the +5V terminal. At this time, if the temperature rises, the resistance of RV becomes smaller, and the voltage at U1 increases at this time. When the temperature of RV is higher than a certain limit temperature value At T1, the voltage of U1 is higher than the U2 voltage value generated by the voltage division of R5 and R6, the operational amplifier N1 outputs a high level, and makes the transistor Q2 conduct. At this time, even if the Pout1 port of the microcontroller outputs a high level, the transistor Q1 will also be Keep off, the contact of relay K1 is disconnected, and the defrosting heater H1 is de-energized.

[0031] The range of T1 can be set to 10~50℃, and the voltage value of U2 can be changed by changing the resistance value of R5 or R6, so as to achieve the purpose of changing the limited temperature value T1.

[0032] The present invention realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com