Micro-perforated sound-absorbing aluminum hollow composite panel

A micro-perforated, composite board technology, used in building components, sound insulation, construction, etc., can solve problems such as poor comprehensive effects, and achieve the effects of good decoration, high sound absorption coefficient, and high sound absorption performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

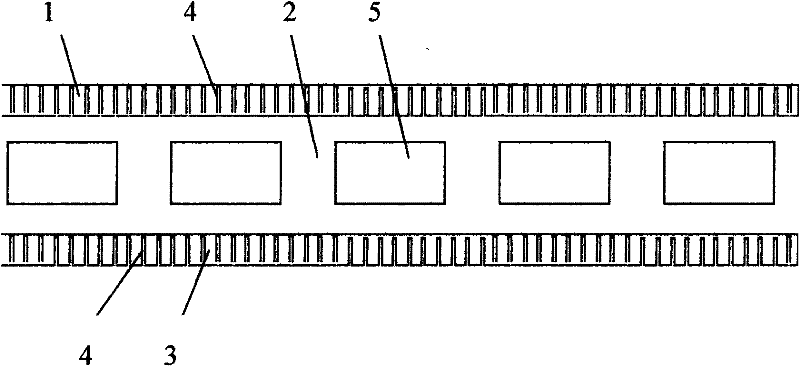

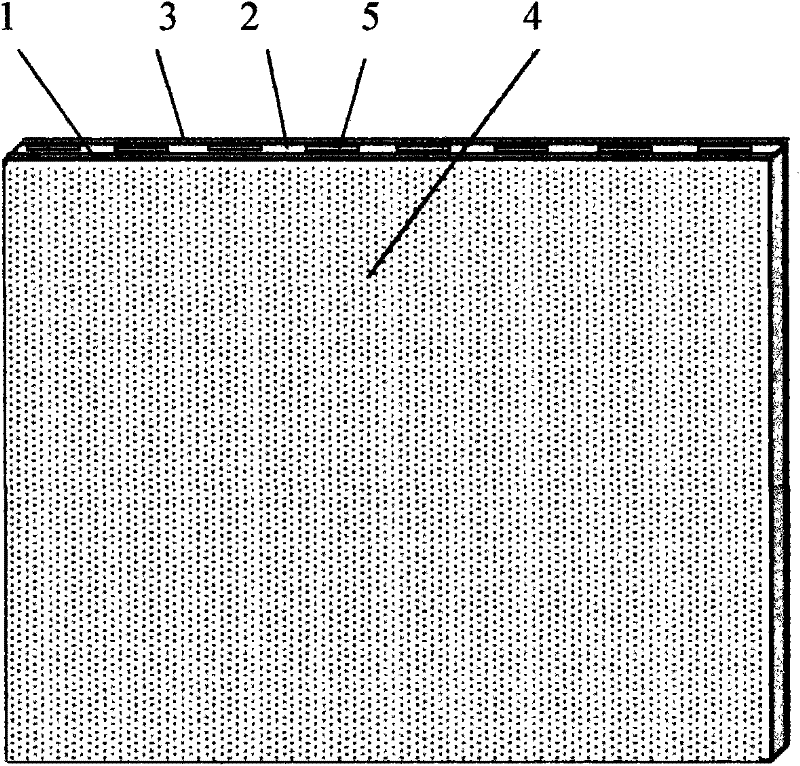

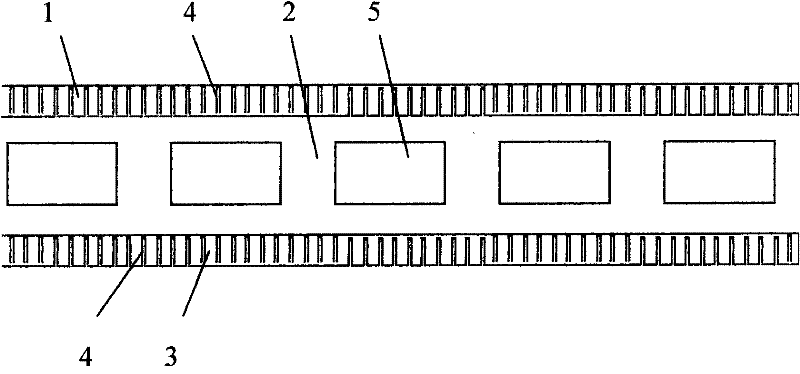

[0013] Such as figure 1 figure 2 As shown, the micro-perforated sound-absorbing aluminum hollow composite panel is a composite panel with a three-layer structure, including a surface layer 1, an intermediate layer 2 and a base layer 3, characterized in that: the surface layer 1 and the base layer 3 are The surface of the aluminum plate is provided with many misplaced micro-perforations 4; the middle layer 2 is a modified polyphenylene ether (MPPO) plastic plate, and a plurality of hollow holes 5 are arranged in the plastic plate.

[0014] The thickness of the aluminum plate of the surface layer 1 and the base layer 3 is 0.5mm-1.0mm; the thickness of the modified polyphenylene ether plate of the middle layer 2 is 6.0mm-10mm.

[0015] The pore diameter of the micro-perforation 4 is not greater than 1.0mm, the hole distance is 4mm-6mm, and the perforation rate is 1-5%.

[0016] The hollow holes 5 in the modified polyphenylene ether plastic plate of the middle layer 2 are compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com