Heat radiation apparatus and manufacture method thereof

A technology of heat dissipation device and manufacturing method, which is applied in the direction of cooling/ventilation/heating transformation, etc., which can solve the problems of low heat transfer and heat dissipation efficiency, long working hours, small heat dissipation space, etc., and achieve the effect of rapid and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

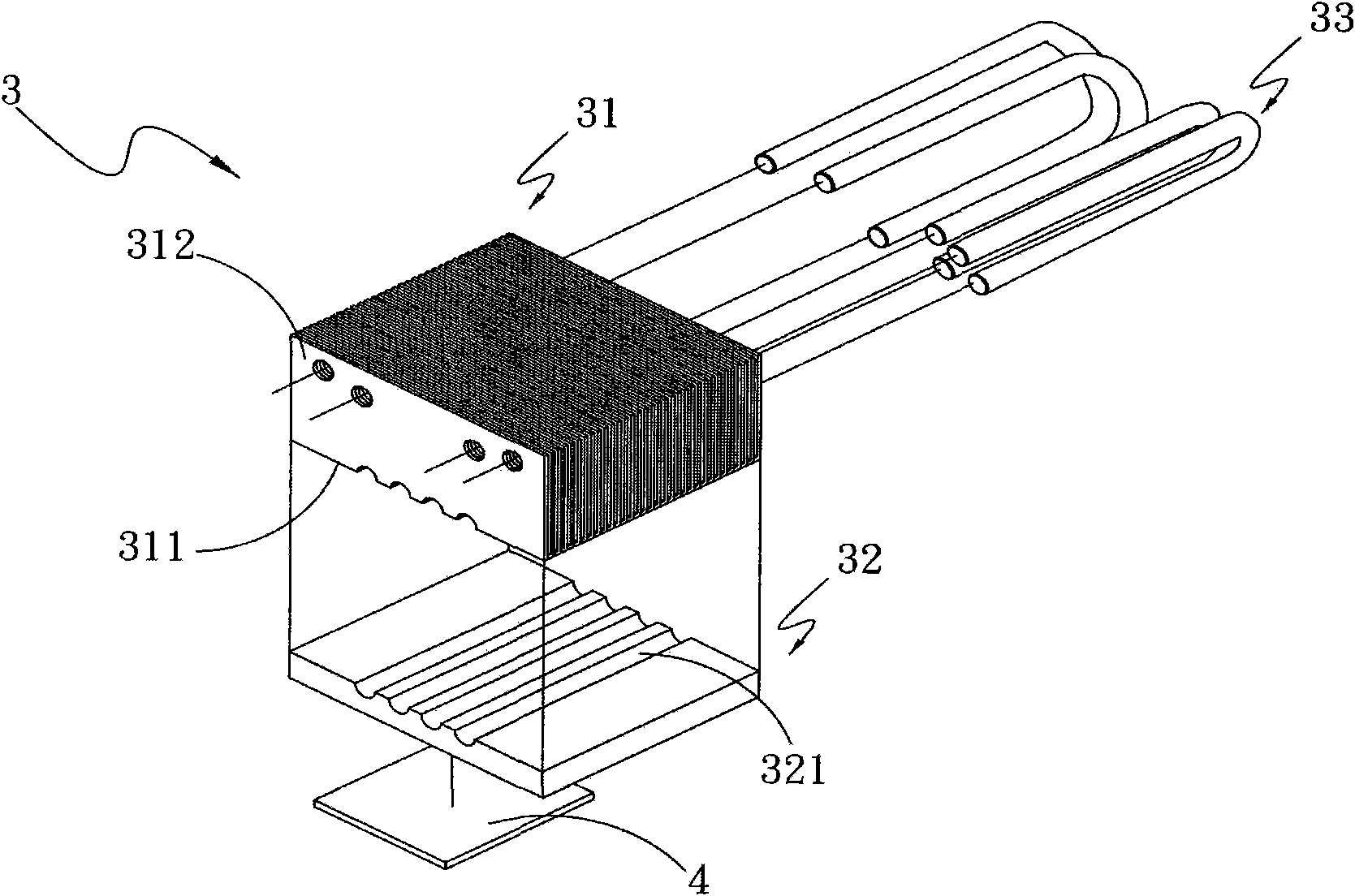

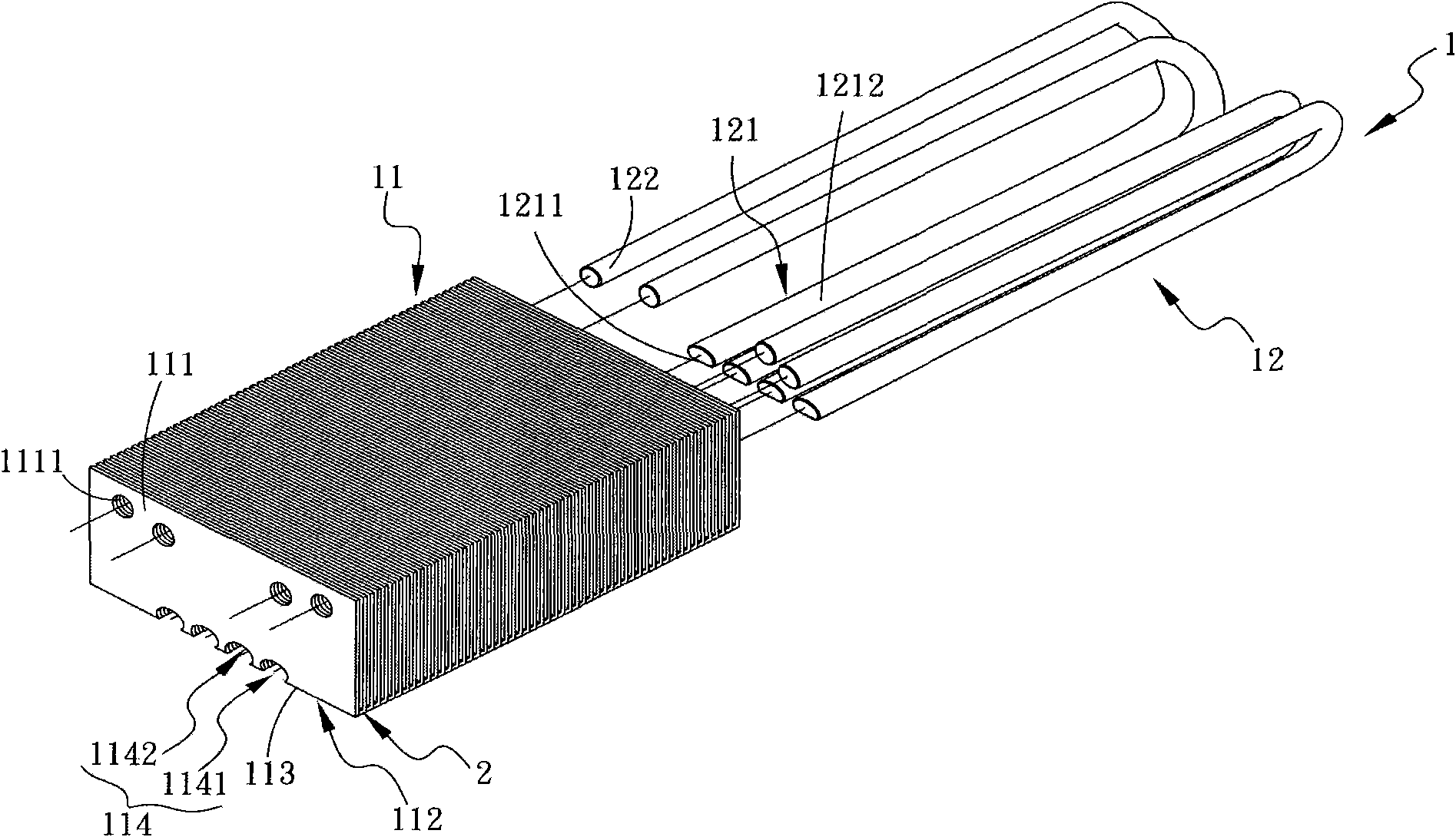

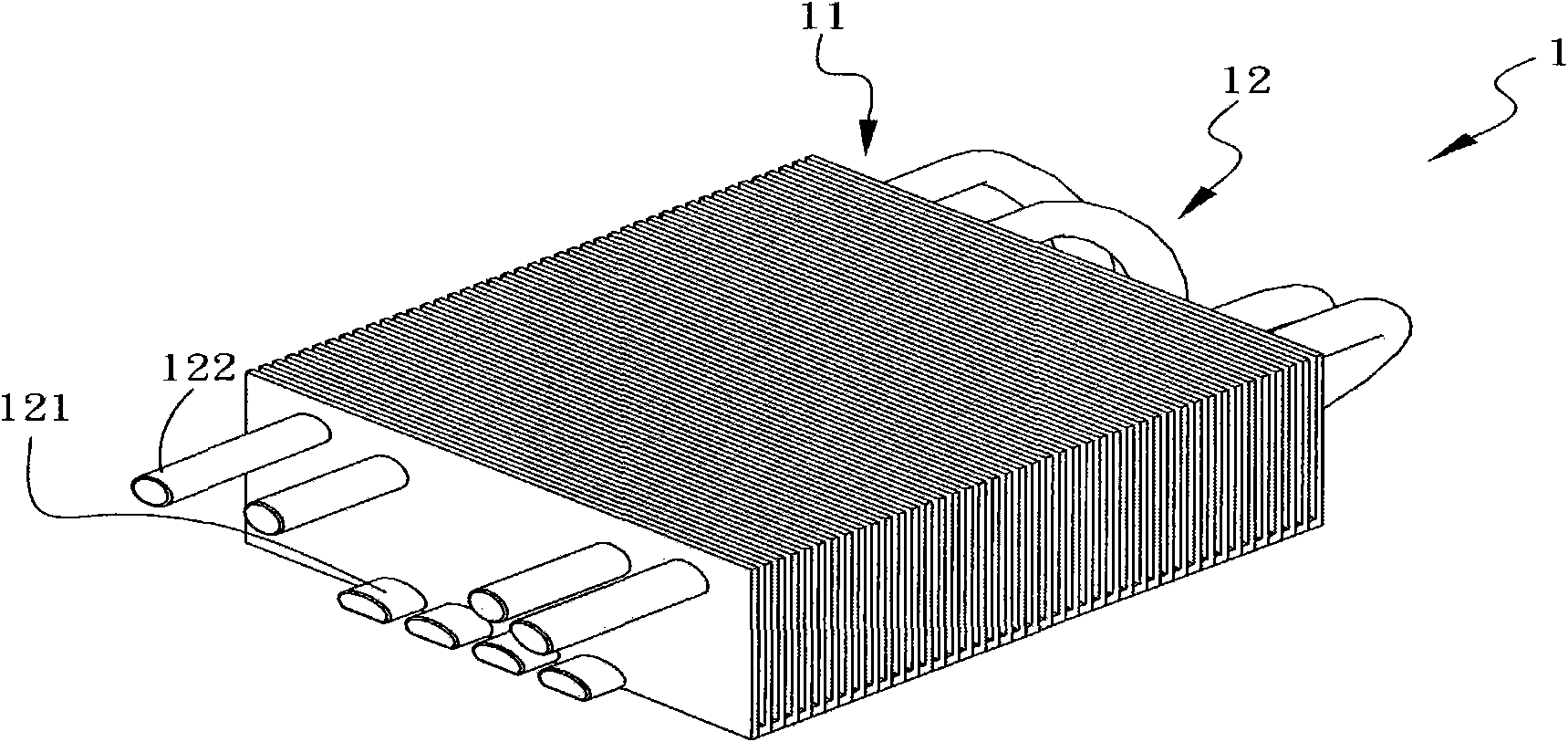

[0045] Please refer to Figures 2, 3, and 4, which are three-dimensional exploded and assembled views and front views of the first embodiment of the heat sink of the present invention. As shown in the figure, the heat sink 1 includes: a radiator 11, at least one heat pipe 12;

[0046] The heat sink 11 has a heat dissipation portion 111 and a heat absorption portion 112, the heat absorption portion 112 has an end surface 113, and the end surface 113 is concavely provided with at least one groove 114, and the groove 114 has an opening 1141 and a closed side 1142, the heat dissipation portion 111 is connected to the heat absorption portion 112, and is configured by extending one side of the heat absorption portion 112 to the opposite direction of the heat absorption portion 112, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com