Polyaniline (PAn) modified ordered mesoporous carbon (EOMC) immobilized laccase biosensor and preparation method

A technology of biosensor and immobilized laccase, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult electron transfer, inactivation, and deformation between enzymes and electrodes, and achieve good sensing performance, good repeatability and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

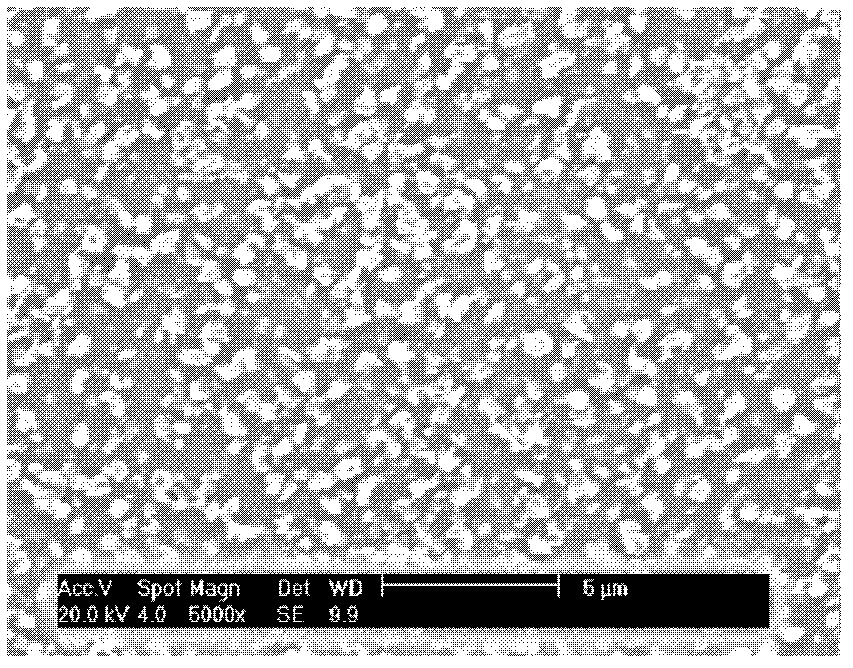

[0041] Dissolve 2.5g epoxy resin in 10ml absolute ethanol, add 0.5g curing agent 2-ethyl-4-methylimidazole, stir for 2h, then add 2g SBA-15, stir well for 12h to make the polymer solution full Disperse in mesoporous silicon SBA-15, then place it in a vacuum drying oven at 100°C for 4 hours to remove the solvent; the mixture prepared above is protected by a N2 atmosphere with a flow rate of 100mL / min, and the temperature rise rate is 5°C / min. Carbonize at 950°C for 6h; finally, soak the resulting product with 40wt% hydrofluoric acid overnight to remove the template, then filter, wash with ethanol and deionized water, and dry at 100°C to constant weight to obtain EOMC. Do transmission electron microscope (TEM) analysis of the prepared EOMC, such as figure 1 As shown, perpendicular to the direction of the EOMC hole axis, it can be clearly seen that the channels are arranged in an orderly linear manner. It can be seen that the structure of EOMC has good long-range order, and it also...

Embodiment 2

[0054] Dissolve 2.5g epoxy resin in 8ml absolute ethanol, add 0.4g curing agent 2-ethyl-4-methylimidazole, stir for 2h, then add 2g SBA-15, stir well for 10h to make the polymer solution full Disperse in mesoporous silicon SBA-15, and then place it in a vacuum drying oven at 80°C for 3 hours to remove the solvent; the mixture prepared above is protected by a N2 atmosphere with a flow rate of 80mL / min, and the temperature rises at a rate of 4°C / min. Carbonize at 800°C for 5h; finally, soak the resulting product with 40wt% hydrofluoric acid overnight to remove the template, then filter, wash with ethanol and deionized water, and dry at 80°C to constant weight to obtain EOMC. Do transmission electron microscope (TEM) analysis of the prepared EOMC, such as figure 1 As shown, perpendicular to the direction of the EOMC hole axis, it can be clearly seen that the channels are arranged in an orderly linear manner. It can be seen that the structure of EOMC has good long-range order, and i...

Embodiment 3

[0067] Dissolve 2.5g epoxy resin in 12ml absolute ethanol, add 0.6g curing agent 2-ethyl-4-methylimidazole, stir for 3h, then add 2g SBA-15, stir well for 15h to make the polymer solution full Disperse in mesoporous silicon SBA-15, then place it in a vacuum drying oven at 100°C for 5 hours to remove the solvent; the mixture prepared above is protected by a N2 atmosphere with a flow rate of 100mL / min, and the temperature rises at a rate of 6°C / min. Carbonize at 1000°C for 8h; finally, soak the obtained product with 40wt% hydrofluoric acid overnight to remove the template, then filter, wash with ethanol and deionized water, and dry at 100°C to constant weight to obtain EOMC. Do transmission electron microscope (TEM) analysis of the prepared EOMC, such as figure 1 As shown, perpendicular to the direction of the EOMC hole axis, it can be clearly seen that the channels are arranged in an orderly linear manner. It can be seen that the structure of EOMC has good long-range order, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com