Preparation method and application of graphene-modified conductive polymer gel-coated metal nanoparticles

A technology of metal nanoparticles and conductive polymers, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as low electrical conductivity and mechanical properties, affect electron transmission in electrode materials, and affect battery cycle performance, etc., to achieve good repeatability The effects of stability, good electron ion transport ability, and fast charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

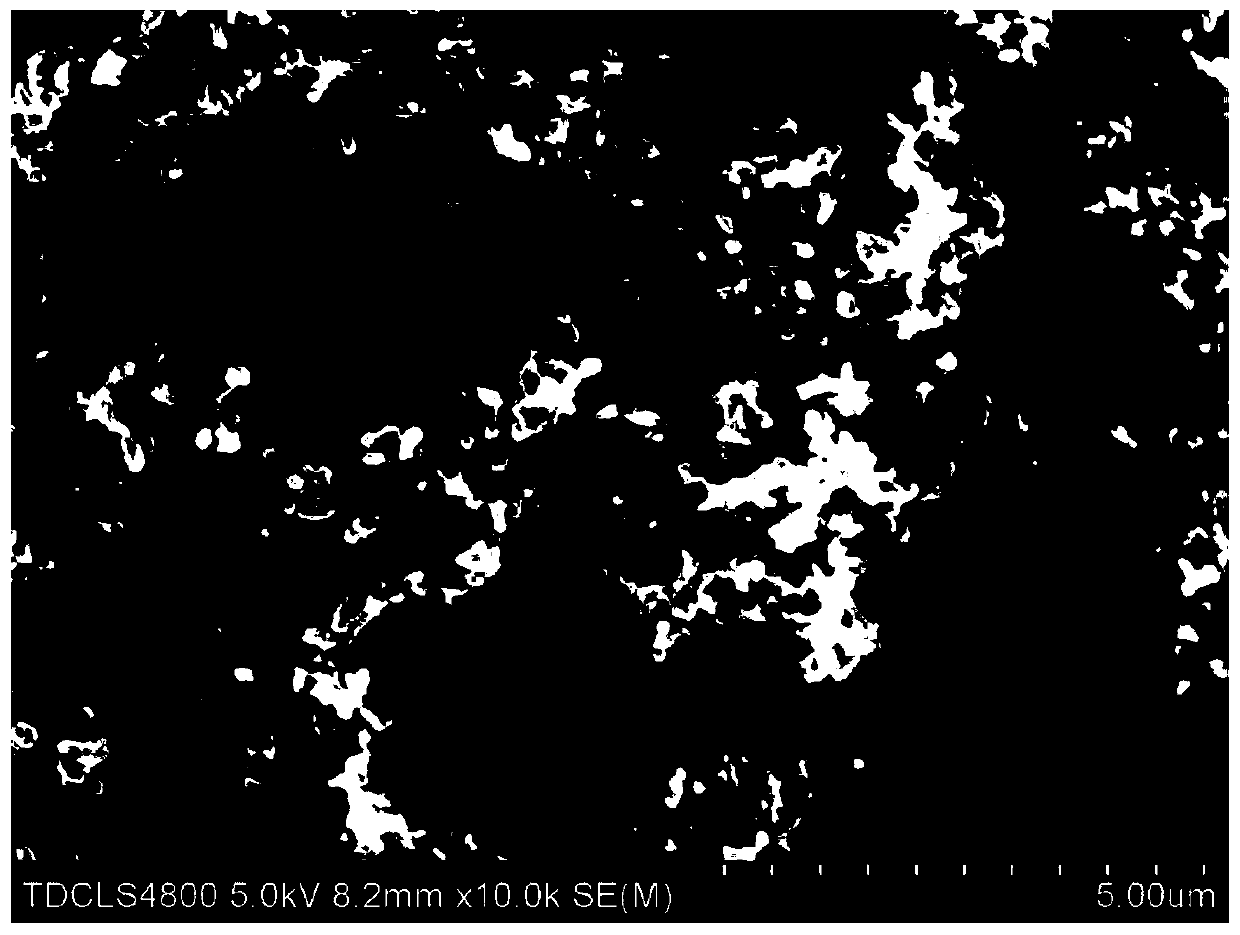

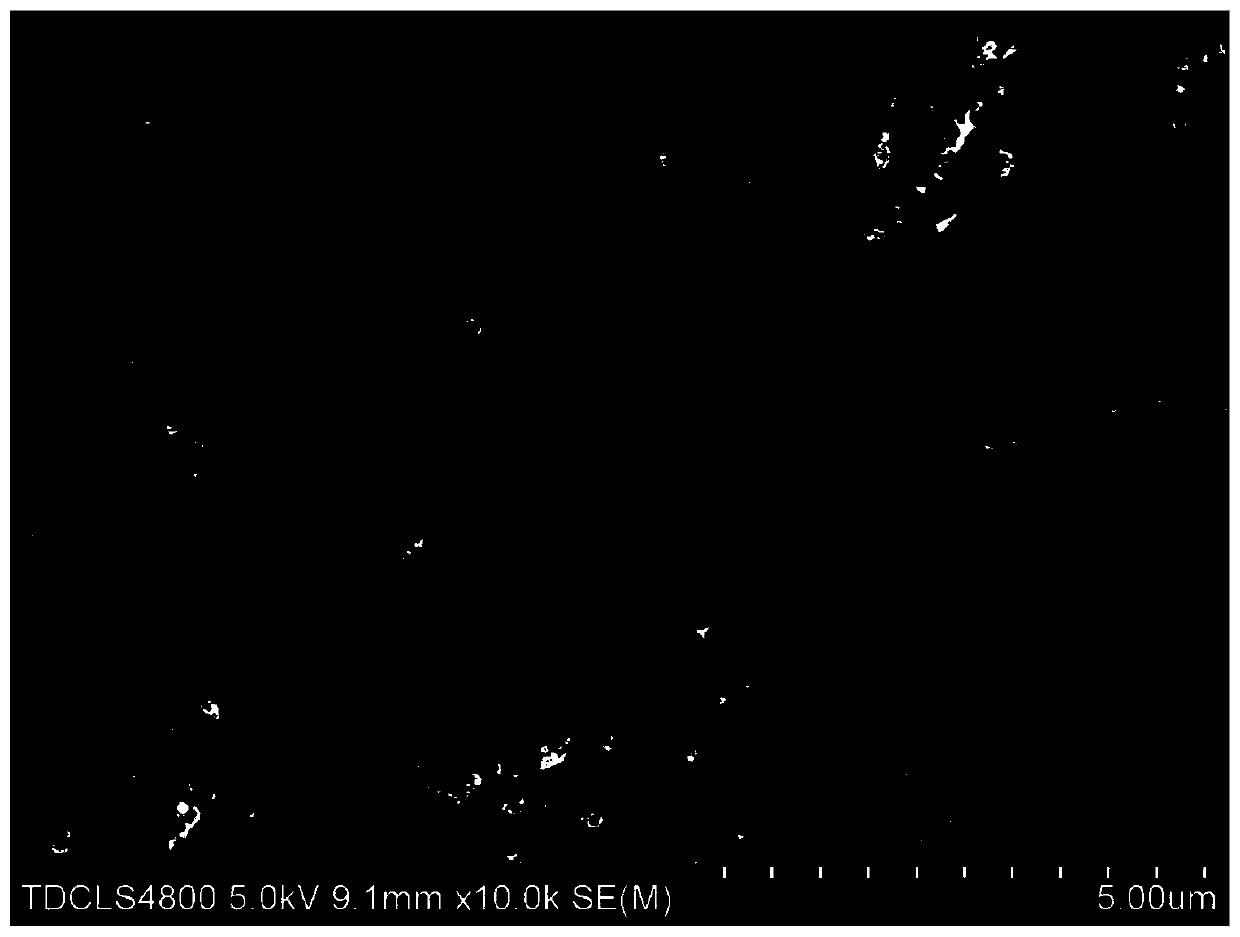

[0027] Add 58mg of tin-nickel nanoparticles into 2mL of 1mg / mL graphene oxide aqueous solution, and ultrasonically disperse them evenly. Then, add 60 μL of phytic acid and 50 μL of pyrrole solution, stir and sonicate to disperse evenly. Finally, add 0.12g of ammonium persulfate to 1mL of distilled water, then add it to the solution prepared in the previous step, ultrasonicate for 30s and let it stand for 8min to make pyrrole polymerize completely, then wash with distilled water for 2-3 times, and then freeze Dry to prepare graphene-modified conductive polymer gel-coated tin-nickel nanoparticles.

[0028] The graphene-modified conductive polymer gel coated tin-nickel nanoparticles prepared in this example has a three-dimensional porous structure, the particles are scattered in the graphene sheet and the gel, and the polypyrrole gel is closely connected with the graphene sheet. The cycle stability of the material is poor, and the capacity drops to 300mAh / g after 100 cycles.

Embodiment 2

[0030] Add 70mg of tin-nickel nanoparticles into 1mL of 2mg / mL graphene oxide aqueous solution, and ultrasonically disperse them evenly. Then, add 70 μL of phytic acid and 60 μL of pyrrole solution, stir and sonicate to disperse evenly. Finally, add 0.13g of ammonium persulfate to 1mL of distilled water, then add it to the solution prepared in the previous step, and let it stand for 8 minutes after ultrasonication for 30s to complete the polymerization of pyrrole, then wash with distilled water for 2-3 times, and then freeze Dry to prepare graphene-modified conductive polymer gel-coated tin-nickel nanoparticles.

[0031] The graphene-modified conductive polymer gel coated tin-nickel nanoparticles prepared in this example has a three-dimensional porous structure, the particles are scattered in the graphene sheet and the gel, and the polypyrrole gel is closely connected with the graphene sheet. The cycle stability of the material is poor, and the capacity drops to 352mAh / g afte...

Embodiment 3

[0033] Add 65mg of tin-nickel nanoparticles into 2mL of 1mg / mL graphene oxide aqueous solution, and ultrasonically disperse them evenly. Then, add 50 μL of phytic acid and 50 μL of pyrrole solution, stir and sonicate to disperse evenly. Finally, add 0.12g of ammonium persulfate to 1mL of distilled water, then add it to the solution prepared in the previous step, ultrasonicate for 30s and let it stand for 15min to make pyrrole polymerize completely, then wash with distilled water for 2-3 times, and then freeze Dry to prepare the graphene-modified conductive polymer gel-coated tin-nickel nanoparticles.

[0034] The graphene-modified conductive polymer gel coated tin-nickel nanoparticles prepared in this example has a three-dimensional porous structure, the particles are scattered in the graphene sheet and the gel, and the polypyrrole gel is closely connected with the graphene sheet. The cycle stability of the material is poor, and the capacity drops to 269mAh / g after 100 cycles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com