Novel tar-free stove integral gasifier

A gasifier and tar-free technology, applied in the field of gasifiers, can solve the problems of clogging pipes and stoves, restricting popularization and application, and discharging condensate water, and achieves the effects of improving gas quality, reducing energy consumption, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

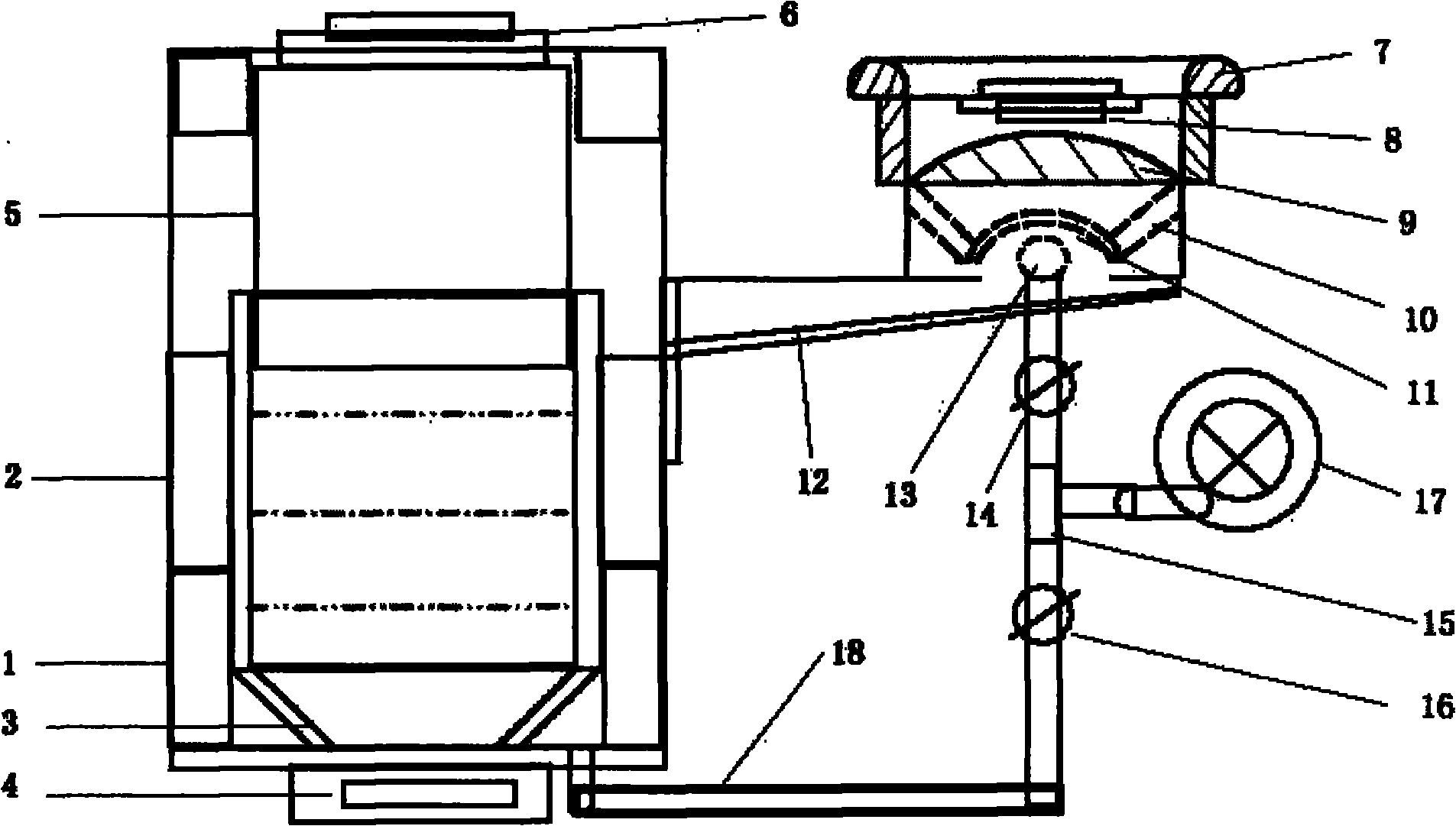

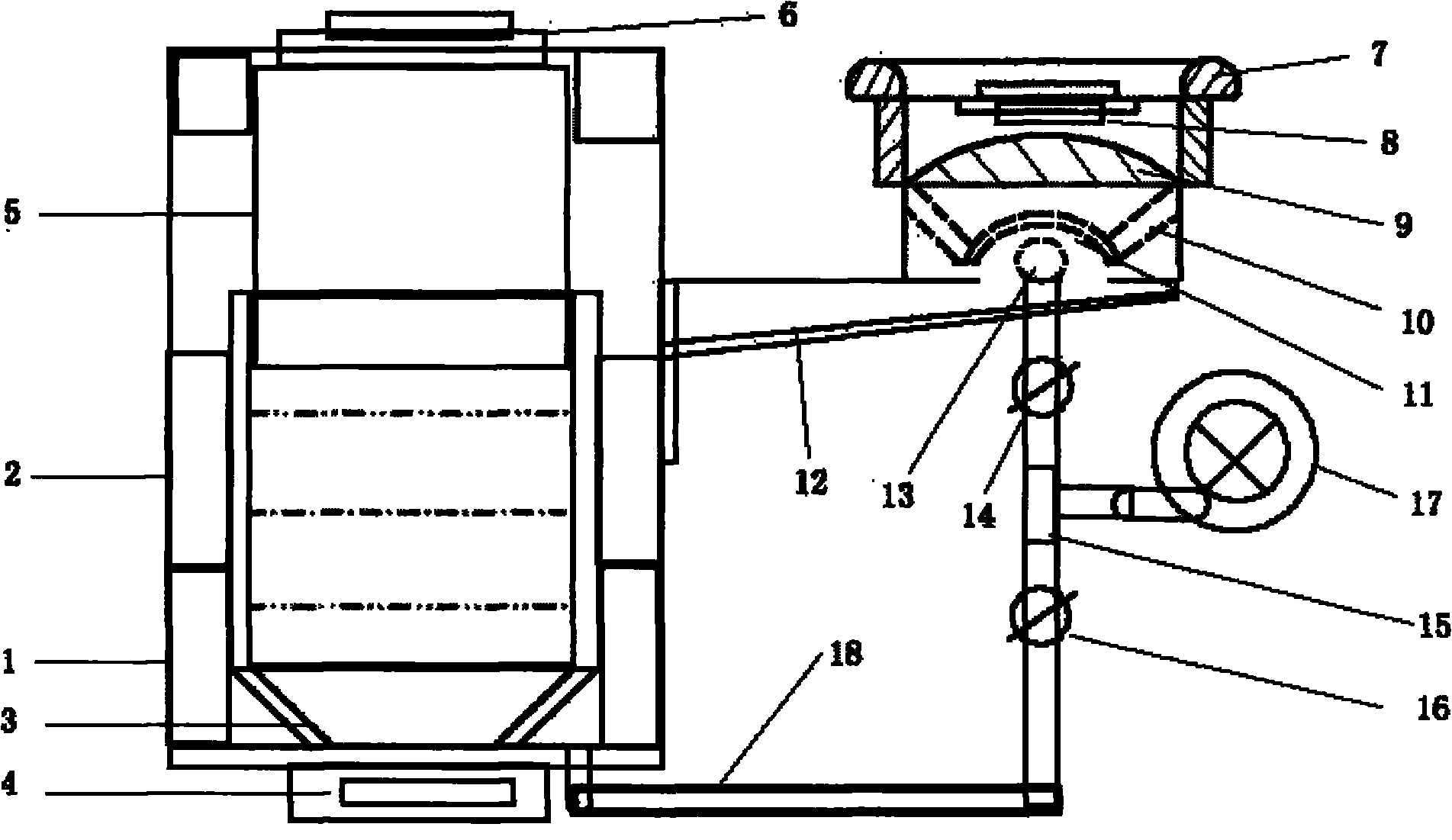

[0015] Such as figure 1 As shown, a new type of tar-free stove integrated gasifier includes an updraft gasifier body with a high-temperature cracking furnace head and an annular tar cracking device.

[0016] The furnace body of the updraft gasifier is equipped with a furnace cover 6 on the top, a feeder 5 in the middle, an annular tar cracking device, a combustion zone 3 and an air supply pipe II 18 at the bottom, and an air inlet pipe 12 on one side .

[0017] The annular tar cracking device communicates with the intake pipe 12, and is provided with a drying layer, a dolomite catalytic cracking layer 2, and a charcoal catalytic cracking layer 1 sequentially from top to bottom; an ash outlet 4 is provided below the combustion zone.

[0018] The high-temperature cracking furnace head is cylindrical, with a gas stove inner wall 7 on the outside, a conical refractory air distribution ring 10 on the bottom, and a horn-type air supply pipe with a return pipe or a return groove on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com