Hydro-cylinder ear ring capable of achieving self-correction and buffer of mounting angle

An oil cylinder earring and installation angle technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of lack of installation angle buffer, self-correction, high manufacturing cost, long production time, etc., and achieve high material utilization and production efficiency. , Avoid excessive material waste, reduce the effect of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0026] As the first technical scheme of the basic design of the present invention:

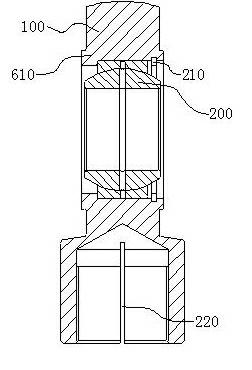

[0027] see figure 1 , figure 2 , image 3 An oil cylinder earring capable of self-correction and buffering of installation angles, including a base body 100, on which an ear hole 600 is opened, and one end of the base body 100 is provided with a centripetal joint bearing 200 to realize installation angle deviation The cushioning and self-correction of the cylinder prevent premature failure of the oil cylinder caused by installation offset and improper processing. The other end is provided with an adjustment device 900. The seat body 100 is forged or cast with a material with good mechanical properties, so it has high material utilization and production effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com