Split type cylinder seat for refrigerator compressor

A technology of compressors and refrigerators, applied in the field of cylinder blocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] refer to figure 1 , The cylinder block used by the traditional refrigerator compressor, its position for the movement of the piston 6 and the rotating shaft 7, is all directly processed from the cylinder block, and is an integrated cylinder block. Normally, the operating speed of the compressor is about 3000~3600r / min. Under such a speed, the frictional heat between the piston 6, the rotating shaft 7 and the moving cavity wall is very serious, so it is necessary to use high temperature resistant , Wear-resistant materials are used to make the cavity wall. For convenience, the traditional manufacturing process is to cast the cylinder block with iron as a whole. But the weight of the cylinder block has just increased like this, and processing is very troublesome.

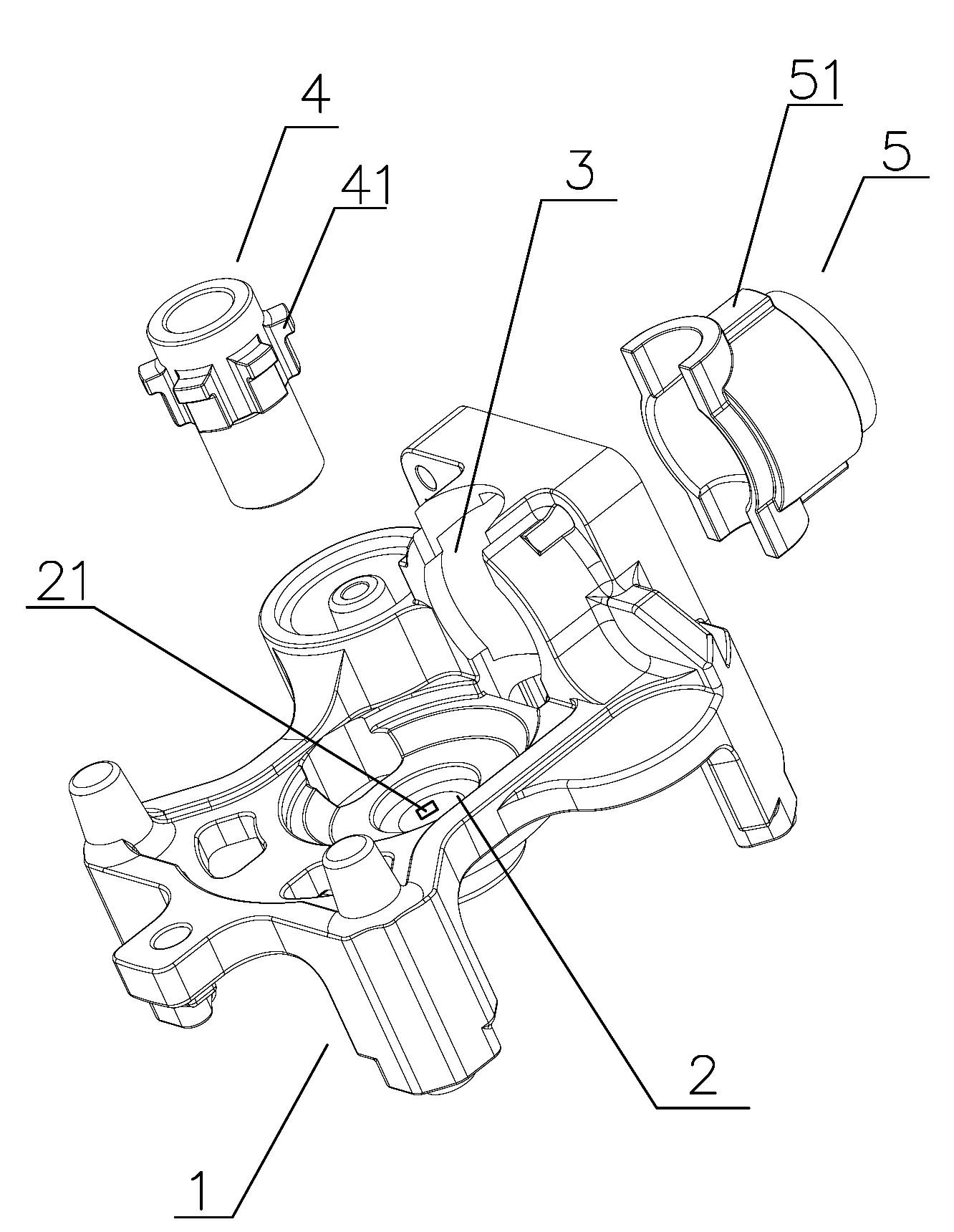

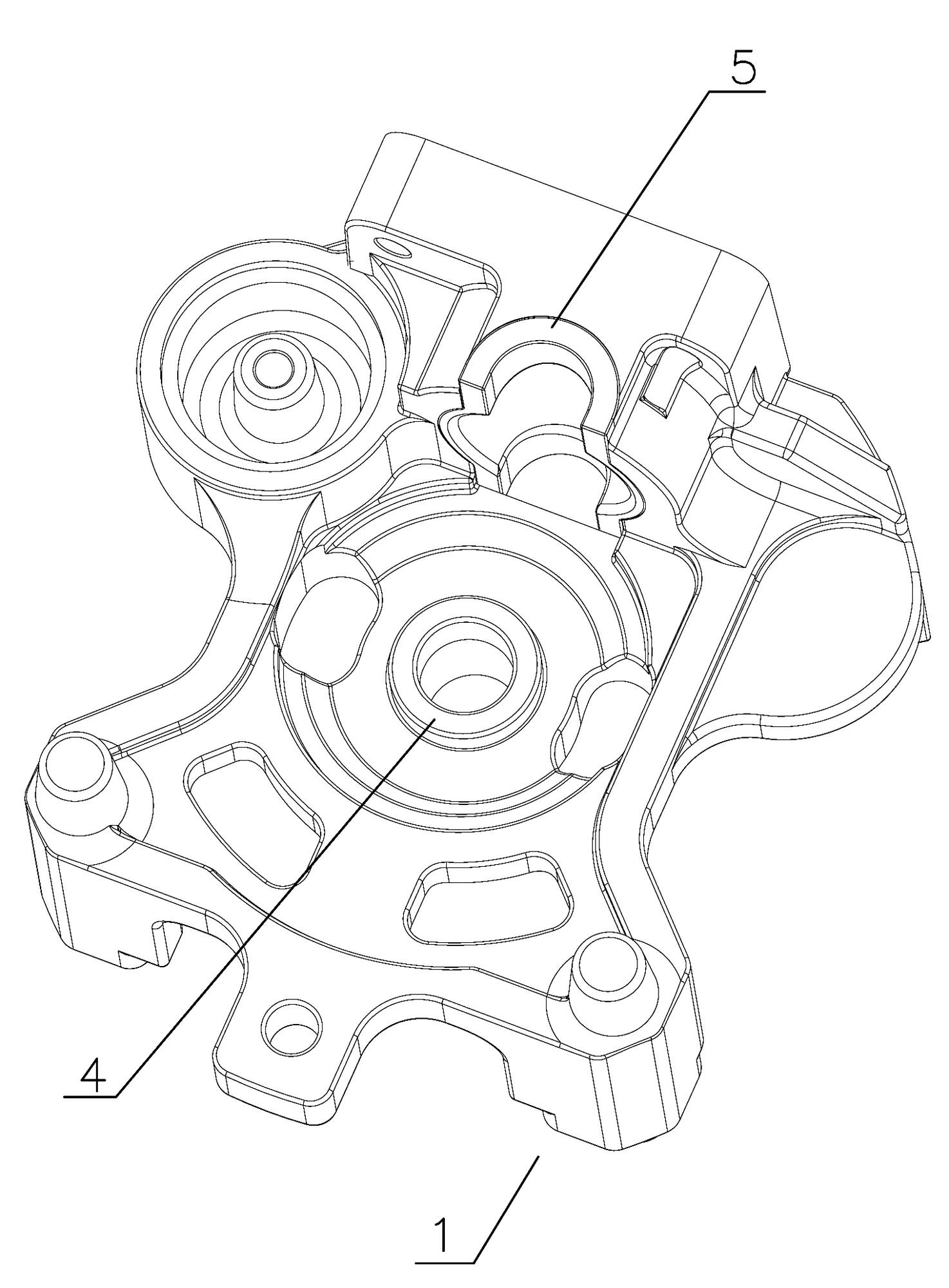

[0024] refer to Figure 2 ~ Figure 3 , a split-type cylinder block for refrigerator compressors, which has a body 1, and the body 1 is provided with a shaft mounting hole 2 and a cylinder mounting hole 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com