Positive pressure type rigid granule high-pressure injection device

A rigid particle, high-pressure injection technology, applied in the direction of drilling with liquid/gas jets, etc., can solve problems such as unsatisfactory effects, and achieve the effects of reasonable structure, high conveying quality, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is not limited by the following examples, and specific implementations can be determined according to the technical solutions and actual conditions of the present invention.

[0016] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is described according to the layout of the drawings in the description, for example, the positional relationship of top, bottom, left, right, etc. determined by the layout direction.

[0017] Below in conjunction with embodiment and accompanying drawing, the present invention is further described:

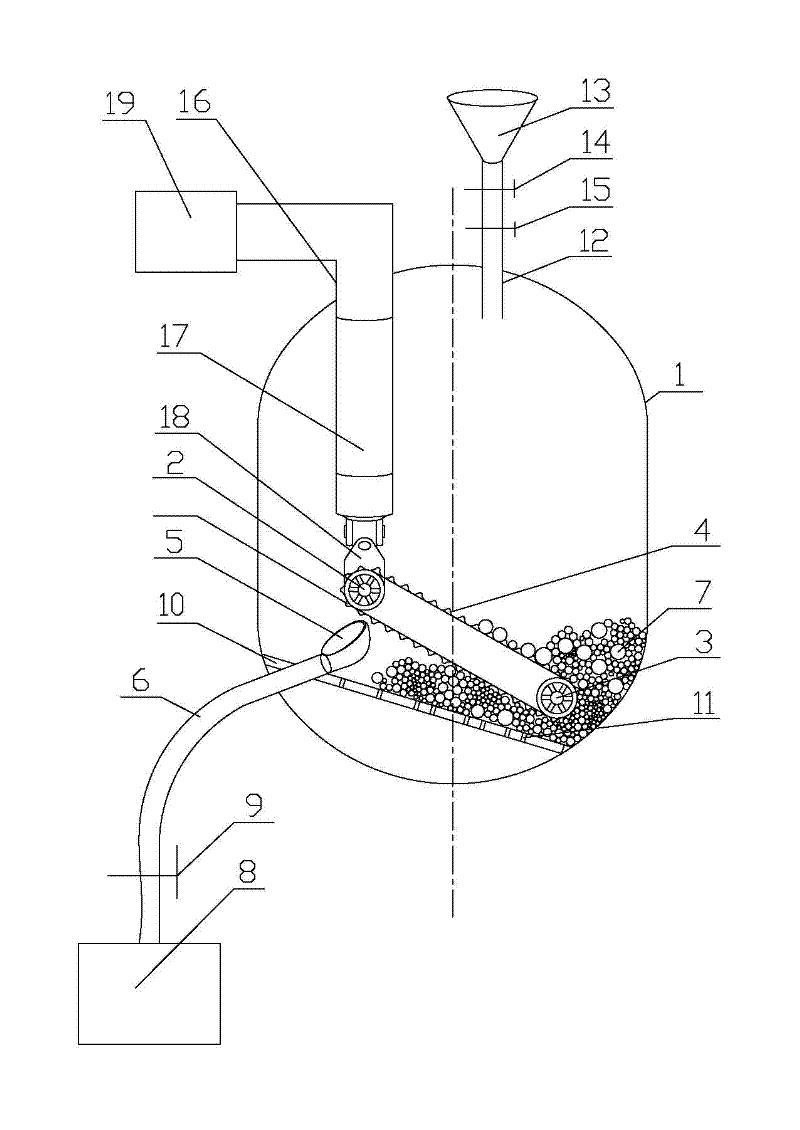

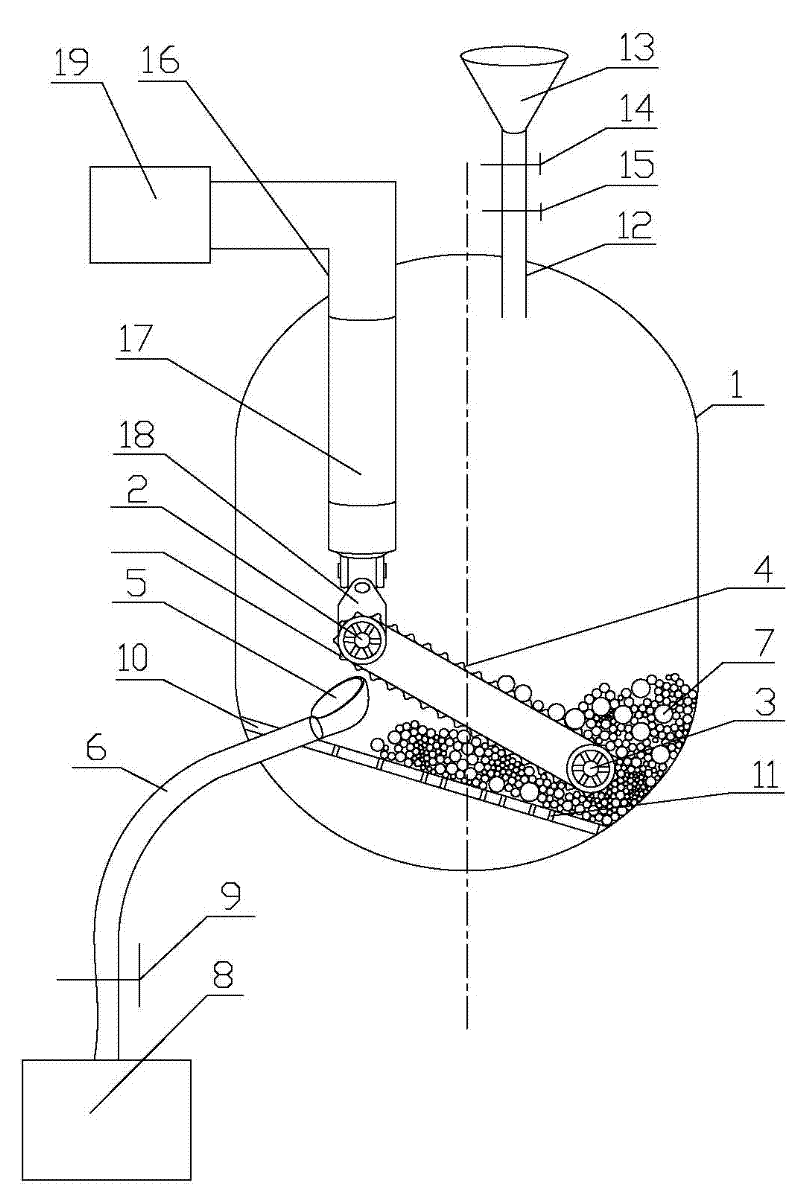

[0018] as attached figure 1 As shown, the positive pressure type rigid particle high-pressure injection device includes a tank body 1, a driving pulley 2, a driven pulley 3, a conveying track 4, a rigid particle scoop 5, a conveying pipe 6 and a transmission device; in the tank body 1 There is a rigid particle inlet in the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com