Low-smoke halogen-free flame-retardant ethylene-propylene-diene mischpolymere rubber

A technology of EPDM rubber and composite flame-retardant system, which is applied in the field of low-smoke, halogen-free flame-retardant EPDM rubber, can solve the problems of poor flame-retardant effect, help flame spread, and limited flame-retardant effect, and achieve The flame retardant effect is not affected, the flame retardant effect is improved, and the flame retardant effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0015] The low-smoke, halogen-free and flame-retardant EPDM rubber of this embodiment is made of the following components in parts by weight:

[0016] 100 parts of EPDM rubber, 9 parts of red phosphorus, 120 parts of magnesium hydroxide, 24 parts of antimony trioxide, 20 parts of kaolin, 3 parts of zinc oxide, 1 part of titanate coupling agent, and 2.5 parts of DCP curing agent. Among them, red phosphorus, magnesium hydroxide, antimony trioxide and kaolin constitute a halogen-free composite flame retardant system. Zinc oxide and titanate coupling agent are processing aids.

[0017] Among them, the third monomer of EPDM rubber is ethylidene norbornene, its ethylene content is ≥60wt%, Mooney viscosity ML(1+4)100℃≥80.

[0018] The purity of red phosphorus is >85%, the ignition point is >340°C, and the mesh number is 1000 mesh.

[0019] The preparation method of the above-mentioned low-smoke, halogen-free and flame-retardant EPDM rubber is a conventional method: after the EPDM r...

Embodiment 2~ Embodiment 4)

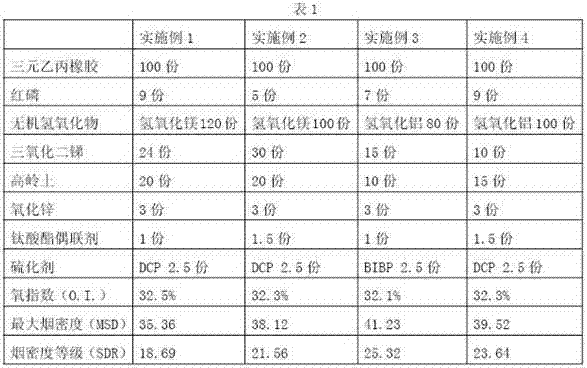

[0022] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com