Hydrophobic swelling polyurethane foam and preparation method and use thereof

A polyurethane foam, hydrophobic technology, applied in separation methods, liquid separation, grease/oily substance/float removal devices, etc., can solve the problems of low hydrophobicity and small volume adsorption, achieve high hydrophobicity, increase adsorption rate , the effect of improving the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

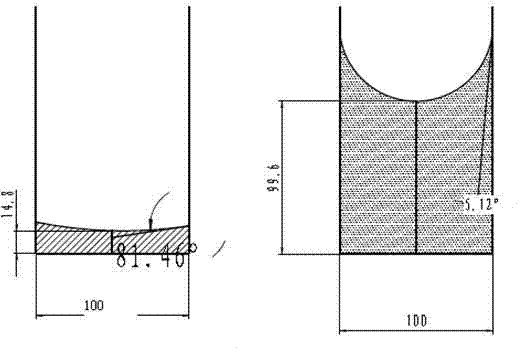

Image

Examples

Embodiment 1

[0056] A kind of hydrophobic swelling polyurethane foam, comprises the component by following parts by weight:

[0057] 20 parts of isocyanate

[0058] Polyol 35 parts

[0059] Catalyst 0.5 parts

[0060] Foam stabilizer 0.5 parts

[0061] Foaming agent 5 parts

[0062] Cell opener 2 parts

[0063] 5 parts of flame retardant;

[0064] Described isocyanate is toluene diisocyanate;

[0065] Described polyhydric alcohol is siloxane grafted hydrophobic polyhydric alcohol;

Embodiment 2

[0068] A kind of hydrophobic swelling polyurethane foam, comprises the component by following parts by weight:

[0069] 40 parts of isocyanate

[0070] Polyol 60 parts

[0071] Catalyst 3 parts

[0072] 3 parts foam stabilizer

[0073] Foaming agent 10 parts

[0074] Cell opener 10 parts

[0075] 20 parts of flame retardant;

[0076] Described isocyanate is diphenylmethane diisocyanate;

[0077] Described polyhydric alcohol is siloxane grafted hydrophobic polyhydric alcohol;

[0078] The catalyst is an organometallic catalyst.

Embodiment 3

[0080] A kind of hydrophobic swelling polyurethane foam, comprises the component by following parts by weight:

[0081] 30 parts of isocyanate

[0082] Polyol 48 parts

[0083] Catalyst 2 parts

[0084] 2 parts foam stabilizer

[0085] Foaming agent 7 parts

[0086] Cell opener 6 parts

[0087] 13 parts of flame retardant;

[0088] Described isocyanate is polymethylene polyphenyl polyisocyanate;

[0089] The catalyst is a composite catalyst of a tertiary ammonia catalyst and an organic metal catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com