Fiber composite material with microwave absorbing function and preparation method thereof

A fiber composite material and composite material technology, which is applied in the field of structure-function composite integrated materials, and can solve problems such as unreported, unreported, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

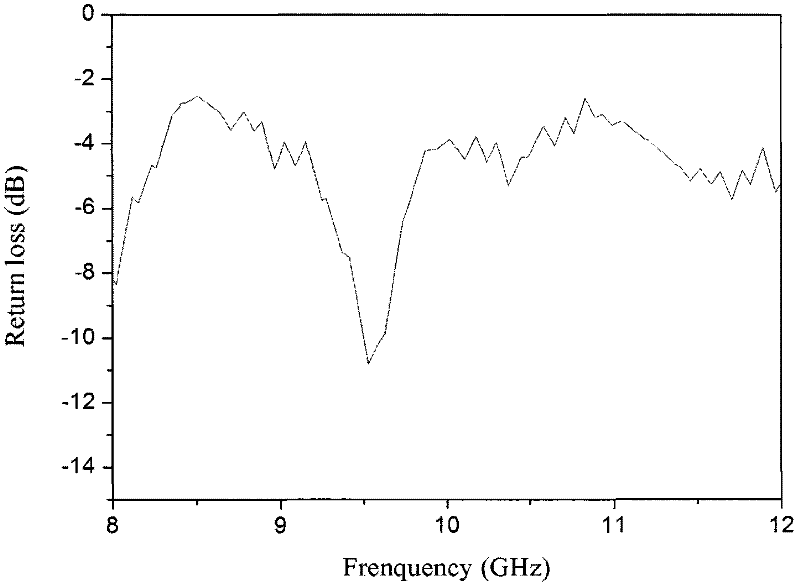

Image

Examples

Embodiment 1

[0044] Take SiO 2f Dipping PTFE emulsion, dry, SiO 2f The mass ratio to polytetrafluoroethylene is 13.3:1. PVA and deionized water were taken and dissolved in a 90° C. water bath for 4 hours to prepare 3.8 wt % PVA (aq). take molten SiO 2 The powder and PVA (aq) are mixed in a mass ratio of 3:2, and deionized water is added as a solvent in such an amount that the solid content of the slurry reaches 45%. Mix the slurry by roller milling. The fiber treated with the coupling agent is dipped into the slurry to hang the slurry, wound on the steel shaft plate, and dried. It is calculated that the fiber accounts for 30% of the mass of the green body after drying. Cut the dried fiber composite green body into a size of 30*35mm required by the hot-pressed sintered abrasive, and stack them in the mold. Sintered on N 2 The hot pressing sintering method is adopted under the protection of the atmosphere, the sintering temperature is 1250-1350°C, the pressure is 30MPa, and the heat p...

Embodiment 2

[0046] ① Take SiO2 2f Dipping PTFE emulsion, dry, SiO 2f The mass ratio with polytetrafluoroethylene is 9.34:1.

[0047] ② Take PVA and deionized water and stir in a 90°C water bath for 4 hours to dissolve and prepare 3.8wt% PVA(aq). Take CNT, molten SiO 2 Powder and PVA (aq) are mixed in a ratio of 3 / 117 / 40 by mass (CNT accounts for CNT / SiO 2 2.5wt% of the composite powder), add deionized water as solvent, the amount of added deionized water makes the solid content of the slurry reach 45%. Mix the slurry by roller milling.

[0048] ③Impregnate the fiber treated with the coupling agent into the slurry to hang the slurry, wind it on the steel shaft plate, and dry it. It is calculated that the fiber accounts for 17.4% of the mass of the green body after drying. Cut the dried fiber composite green body into a size of 30*35mm required by the hot-pressed sintered abrasive, and stack them in the mold.

[0049] ④ in N 2 Under the protection of the atmosphere, the hot pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com