Vertical lathe grinding device

A vertical lathe and grinding technology, used in grinding/polishing equipment, grinding machines, metal processing equipment, etc., can solve problems such as inability to grind workpieces, and achieve the effect of increasing service life and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

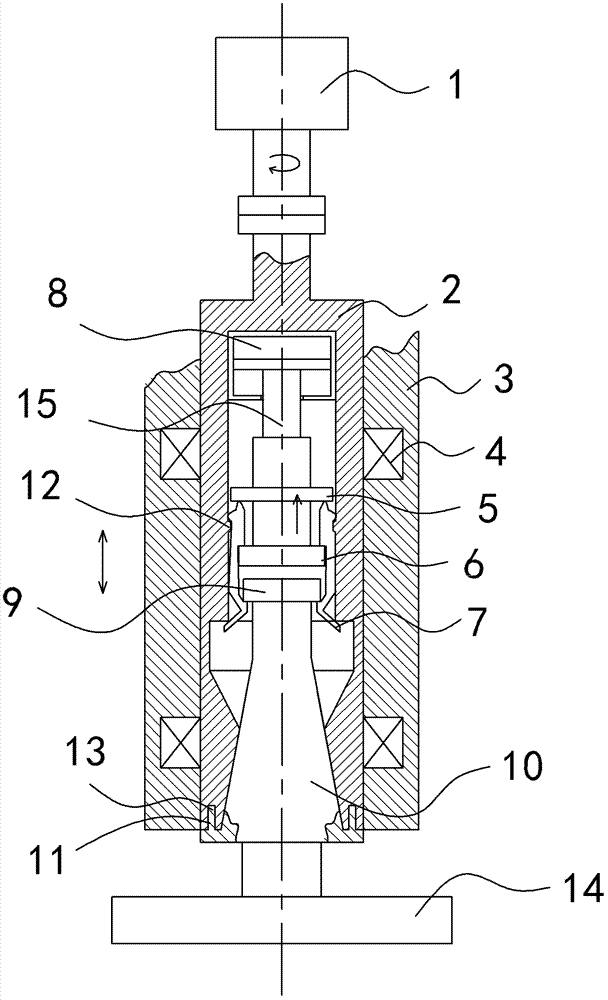

[0019] Embodiment: A kind of vertical lathe grinding device

[0020] See attached figure 1 , attached figure 2 As shown, the vertically arranged spool 3 on the vertical lathe is a hollow structure, and a rotating shaft 2 is vertically arranged in the cavity of the hollow structure of the spool 3, and the rotating shaft 2 and the spool 3 rotate through a bearing 4 Support, the upper end of the rotating shaft 2 is provided with a servo motor 1, and the servo motor 1 is connected with the rotating shaft 2 through transmission;

[0021] The rotating shaft 2 is also a hollow structure, and a linear drive mechanism 8 is fixedly arranged on the top of the cavity of the hollow structure of the rotating shaft 2. A drive rod 15 protrudes from the lower end of the linear drive mechanism 8, and a grasping device is connected to the lower end of the drive rod 15. The gripping device is composed of a gripping head and at least two gripping claws 7 that are movably connected to the grippi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com