Fixture device for steel plate laser welding machine and implementation method

A fixture device and steel plate technology, which is applied to laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problem that the fixture cannot clamp steel plates straight, and achieve the effects of improving welding quality, prolonging service life, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention are described in detail below with reference to the accompanying drawings, but are only for illustration rather than limitation of the present invention.

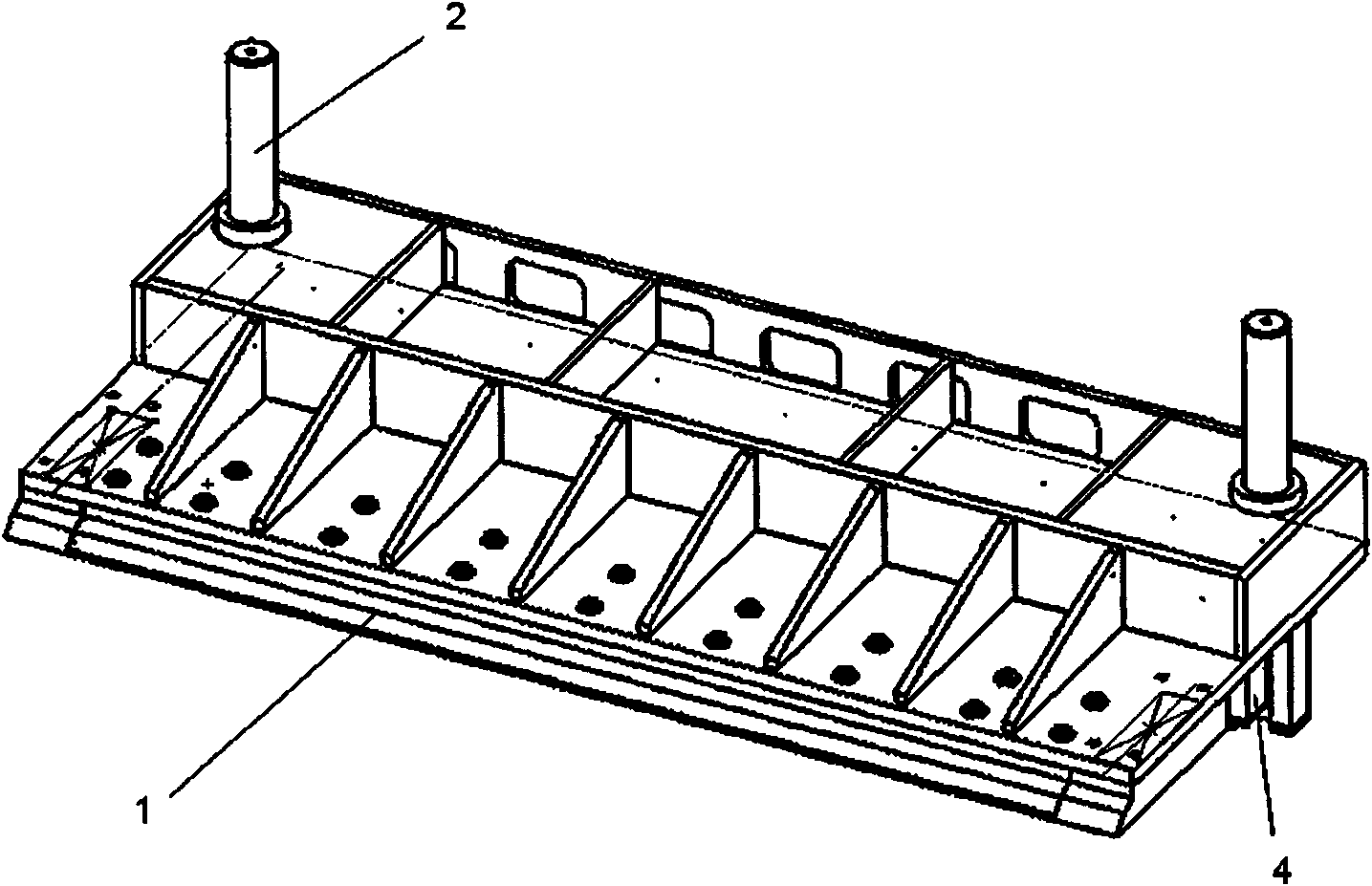

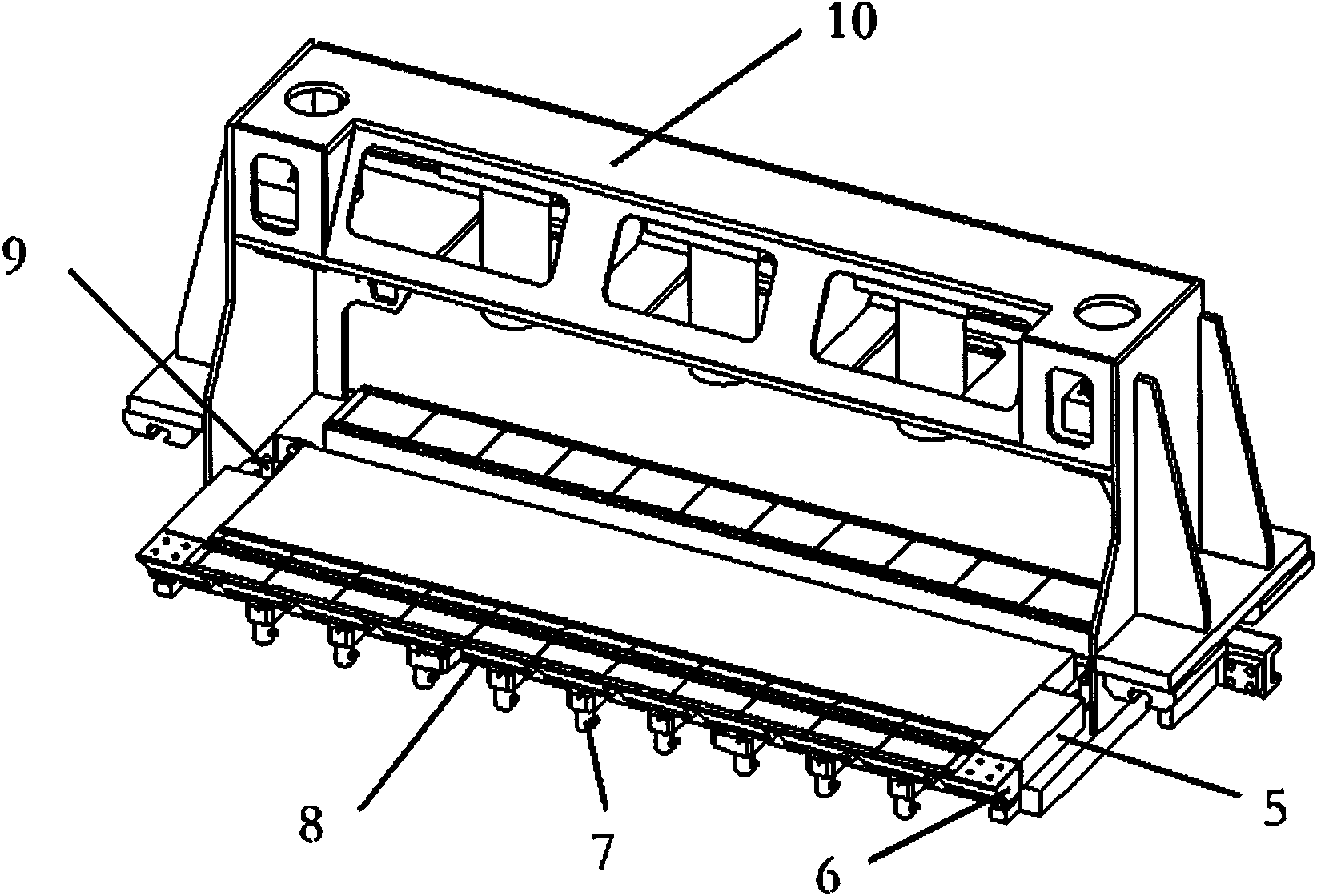

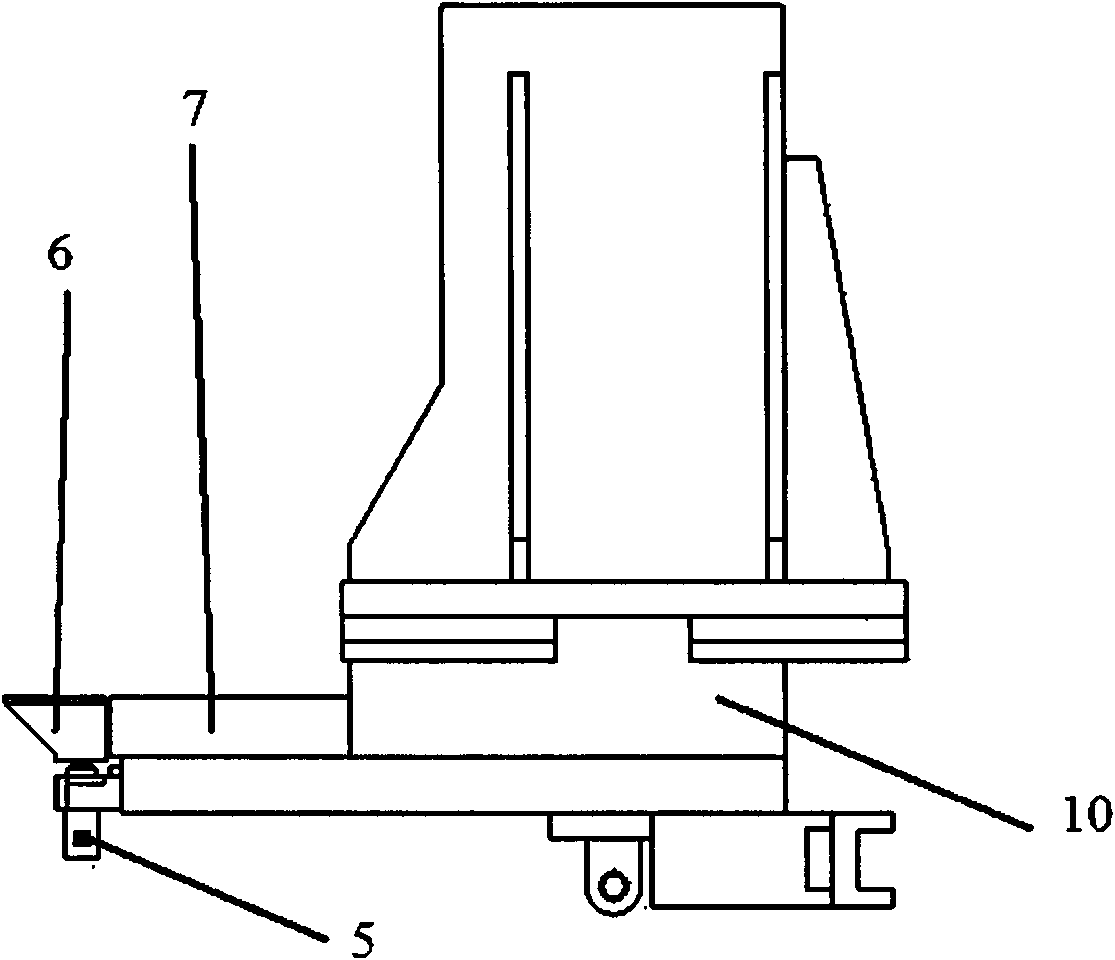

[0030] As shown in the figure, 1-upper splint, 2-cylindrical guide rail, 3-upper splint hydraulic cylinder, 4-locating pin sleeve, 5-lower splint, 6-flexible splint, 7-miniature hydraulic cylinder, 8-suspension slider, 9-location pin rod, 10-cabinet mechanism, 11-clamp base.

[0031] The clamping device (isometric view of clamp) for anti-wear steel plate laser welding machine with leveling function of the present invention mainly includes an upper clamping mechanism (isometric view of the upper clamping plate), a lower clamping plate mechanism (isometric view of the lower clamping plate) and a box mechanism .

[0032] Said upper splint mechanism includes an upper splint 1, a cylindrical guide rail 2, an upper splint hydraulic cylinder 3, and a positioning pin sleeve 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com