Technology for restoring polychlorinated biphenyls (PCBs) polluted site through solvothermal method

A solvothermal method and site technology, applied in the restoration of contaminated soil, etc., to achieve good application prospects, reduce transportation costs, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

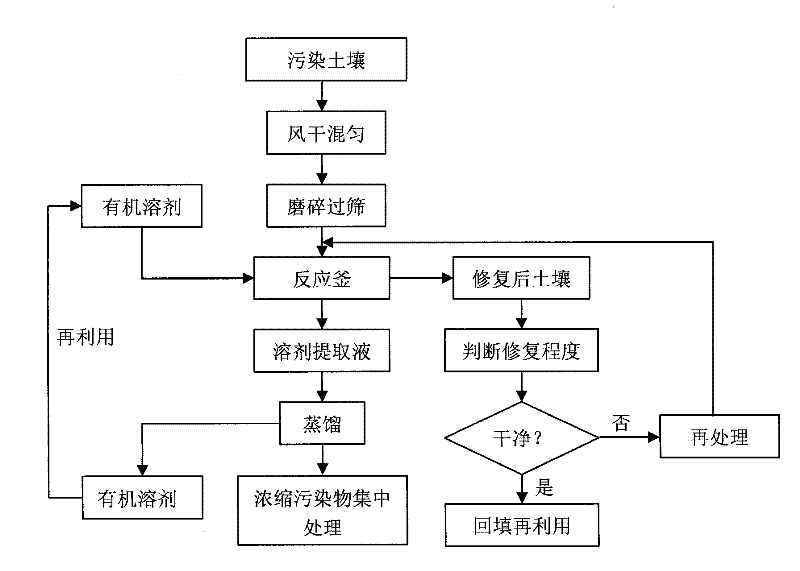

[0016] The process of repairing PCBs contaminated sites by solvothermal method specifically includes the following steps:

[0017] refer to figure 1 Technological process, the clean soil is mixed and dried at room temperature, crushed and passed through an 80-mesh sieve to ensure uniform particle size. Pipette 1ml of diluted capacitor oil (18ppm, Aroclor 1242) and transformer oil (60ppm, Aroclor 1260) as pollution sources, mix with 1g of soil, add n-hexane to fully saturate the soil (soak), and place in a constant temperature shaking box at 20°C Shake to mix the sample evenly. After 48 hours, the n-hexane in the sample was evaporated to dryness at room temperature, and stored in a dark, ventilated place for future use. Put the obtained artificial PCBs-contaminated soil into a hydrothermal reaction kettle, and add 15ml of isopropanol. Put the sealed kettle in an oven, turn on the heating device, raise the temperature to 150° C., and keep the temperature at a constant tempera...

Embodiment 2

[0019] The process of repairing PCBs contaminated sites by solvothermal method specifically includes the following steps:

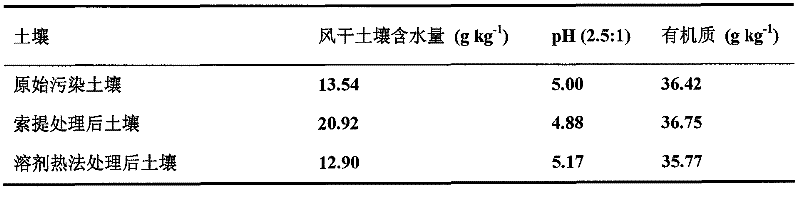

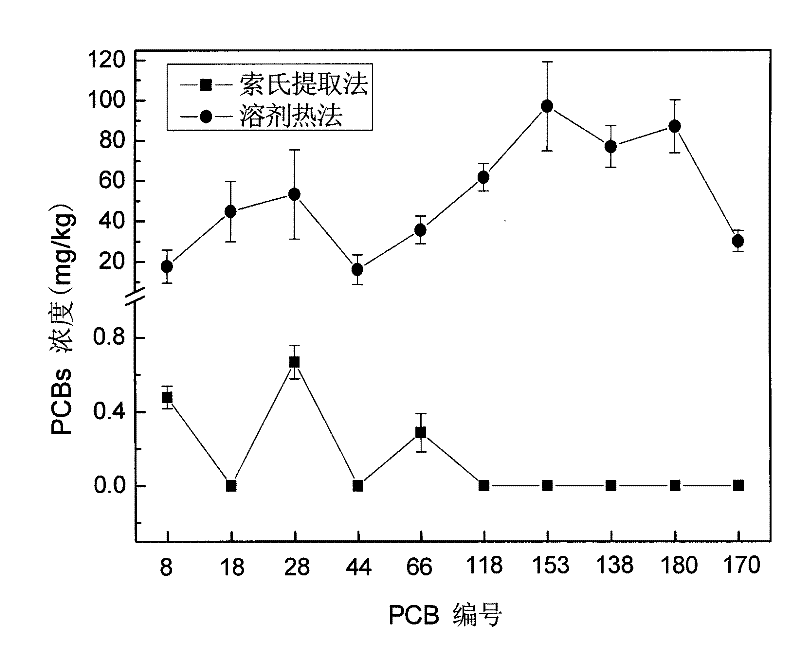

[0020] according to figure 1 Process flow: Mix and dry the PCBs contaminated soil at the waste transformer dismantling site at room temperature, crush it and pass it through an 80-mesh sieve, put it into a hydrothermal reaction kettle, and add 15ml of isopropanol. Put the sealed kettle in an oven, turn on the heating device, raise the temperature to 150° C., and keep the constant temperature for 8 hours until the reaction ends. After the reaction kettle is cooled, the supernatant in the kettle is collected, which is the isopropanol extract, and the isopropanol is recovered by distillation. The concentrated PCBs are purified by sulfuric acid, copper powder vibration to remove sulfur, silicon magnesium adsorbent purification, GC -MS analysis shows that the concentration of PCBs in the extract is 564ppm; while using the traditional Soxhlet extraction method...

Embodiment 3

[0022] The process of repairing PCBs contaminated sites by solvothermal method specifically includes the following steps:

[0023] Mix and dry the actual PCBs-contaminated soil at room temperature, crush it and pass through an 80-mesh sieve, put it into a hydrothermal reaction kettle, and add 15ml of isopropanol. Put the sealed kettle in an oven, turn on the heating device, raise the temperature to 150° C., and keep the temperature at a constant temperature for 10 hours until the reaction is completed. After the kettle is cooled, the supernatant in the kettle is collected, which is the isopropanol extract, and the isopropanol is recovered by distillation. The concentrated PCBs are purified by sulfuric acid, copper powder vibration to remove sulfur, silicon magnesium adsorbent purification, GC- According to MS analysis, the extraction amount of PCBs was 754ppm, and the recovery rate of PCB209 was 80%, meeting the requirements of EPA8082. The content of PCBs in the treated soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com