Method for preparing pulse activating decoction

A technology of Shengmaiyin and red ginseng, which is applied in the field of preparation of traditional Chinese medicine preparations, can solve the problems of low recovery rate of active ingredients, volatile loss of ethanol, long production cycle, etc., and achieve environmental protection, shorten extraction time, and extract efficiency Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prescription: Red Ginseng 5kg, Ophiopogon japonicus 10kg, Schisandra 5kg

[0027] The preparation method comprises the following steps:

[0028] a. Mix the prescribed amount of red ginseng, Ophiopogon japonicus and Schisandra chinensis, crush into coarse powder, and set aside;

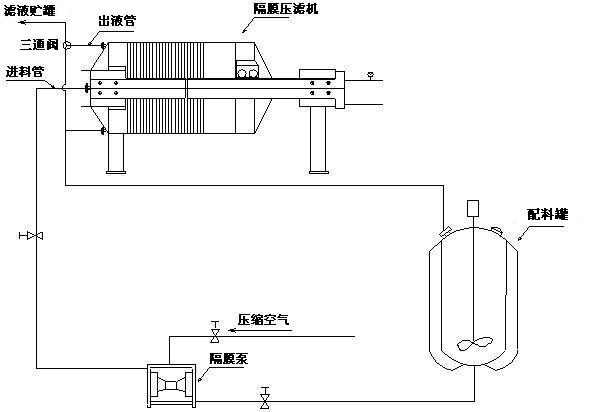

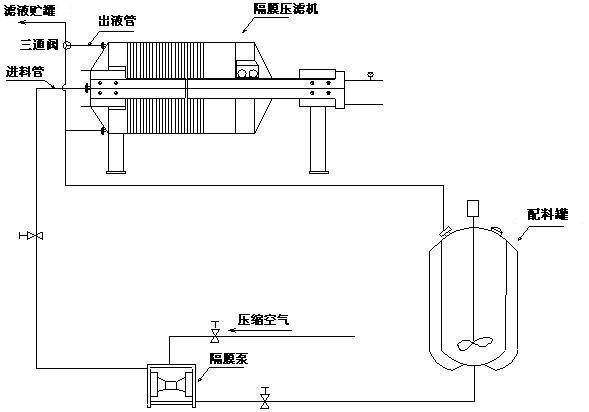

[0029] b. Add 65% ethanol equivalent to 7 times the total weight of red ginseng, Ophiopogon japonicus and Schisandra chinensis into the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, and mix the ingredients The 65% ethanol in the tank is pumped into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the medicine powder obtained in step a into the batching tank at a constant speed, after the addition is completed, the membrane filter press cycle extracts for 35 minutes, and then the thre...

Embodiment 2

[0033] Prescription: Red Ginseng 5kg, Ophiopogon japonicus 10kg, Schisandra 5kg

[0034] The preparation method comprises the following steps:

[0035] a. Mix the prescribed amount of red ginseng, Ophiopogon japonicus and Schisandra chinensis, crush into coarse powder, and set aside;

[0036] b. Add 65% ethanol equivalent to 6 times the total weight of red ginseng, Ophiopogon japonicus and Schisandra chinensis into the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, and mix the ingredients The 65% ethanol in the tank is pumped into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the powder obtained in step a into the batching tank at a constant speed, after the addition is completed, the membrane filter press cycle extracts for 40 minutes, and then the three-way val...

Embodiment 3

[0040] Prescription: Red Ginseng 5kg, Ophiopogon japonicus 10kg, Schisandra 5kg

[0041] The preparation method comprises the following steps:

[0042] a. Mix the prescribed amount of red ginseng, Ophiopogon japonicus and Schisandra chinensis, crush into coarse powder, and set aside;

[0043] b. Add 65% ethanol equivalent to 8 times the total weight of red ginseng, Ophiopogon japonicus and Schisandra chinensis into the batching tank; switch the three-way valve to the batching tank position, open the agitator, diaphragm pump and diaphragm filter press of the batching tank, and mix the ingredients The 65% ethanol in the tank is pumped into the membrane filter press (using 5-8 L / m 2 .s polypropylene multifilament filter cloth), when the press filtrate flows back into the batching tank, add the medicine powder obtained in step a into the batching tank at a constant speed, after the addition is completed, the membrane filter press cycle extracts for 30 minutes, and then the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com