White light LED (light emitting diode) encapsulation structure and method

A technology of LED encapsulation and encapsulation method, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of uneven coating amount of phosphor powder coating, improve uniformity and luminous efficiency, improve color consistency, The effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

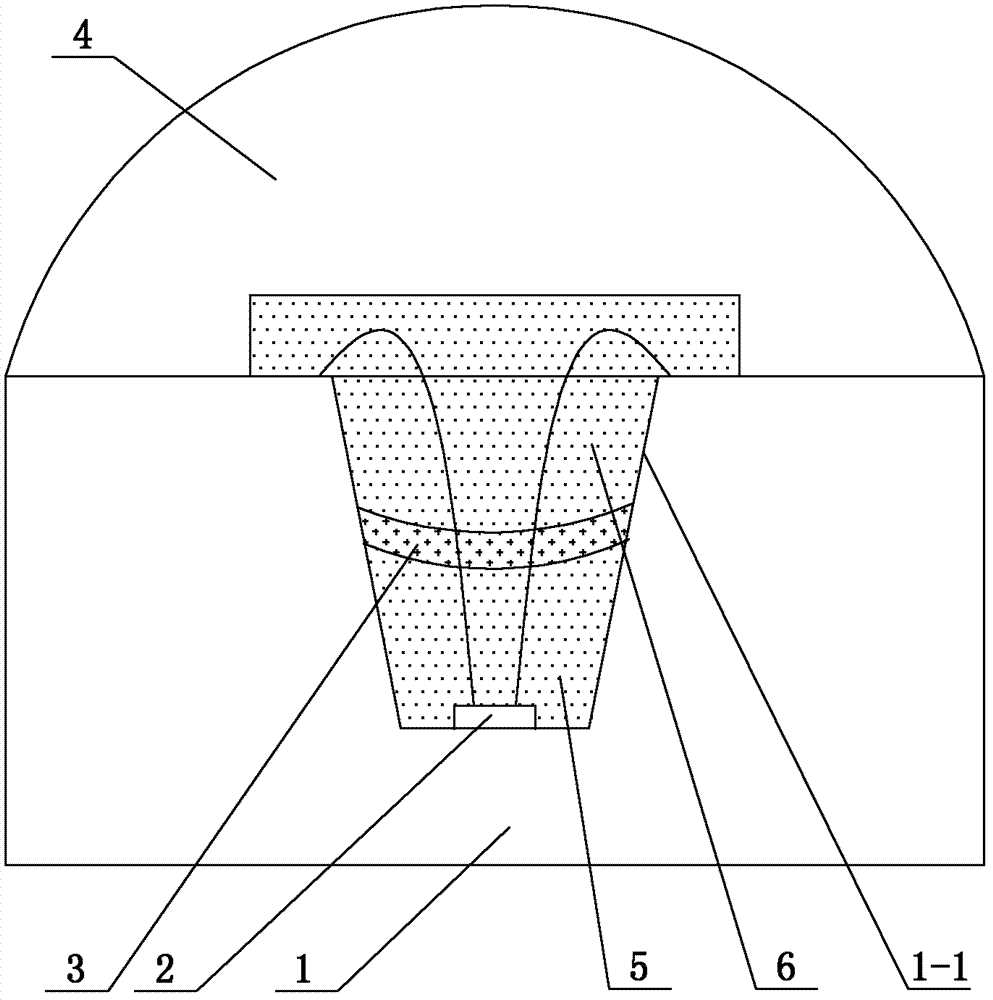

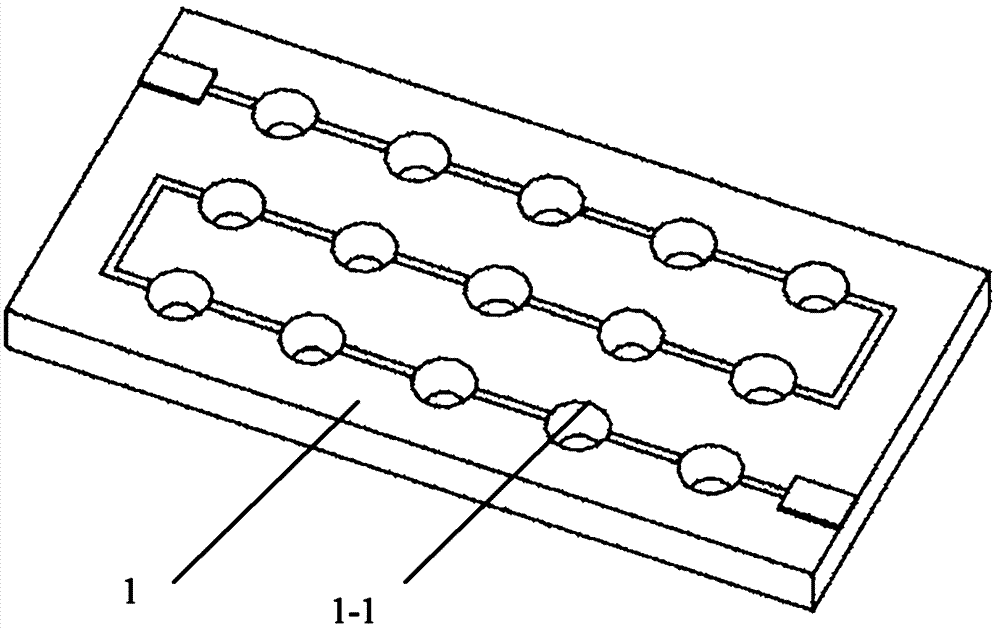

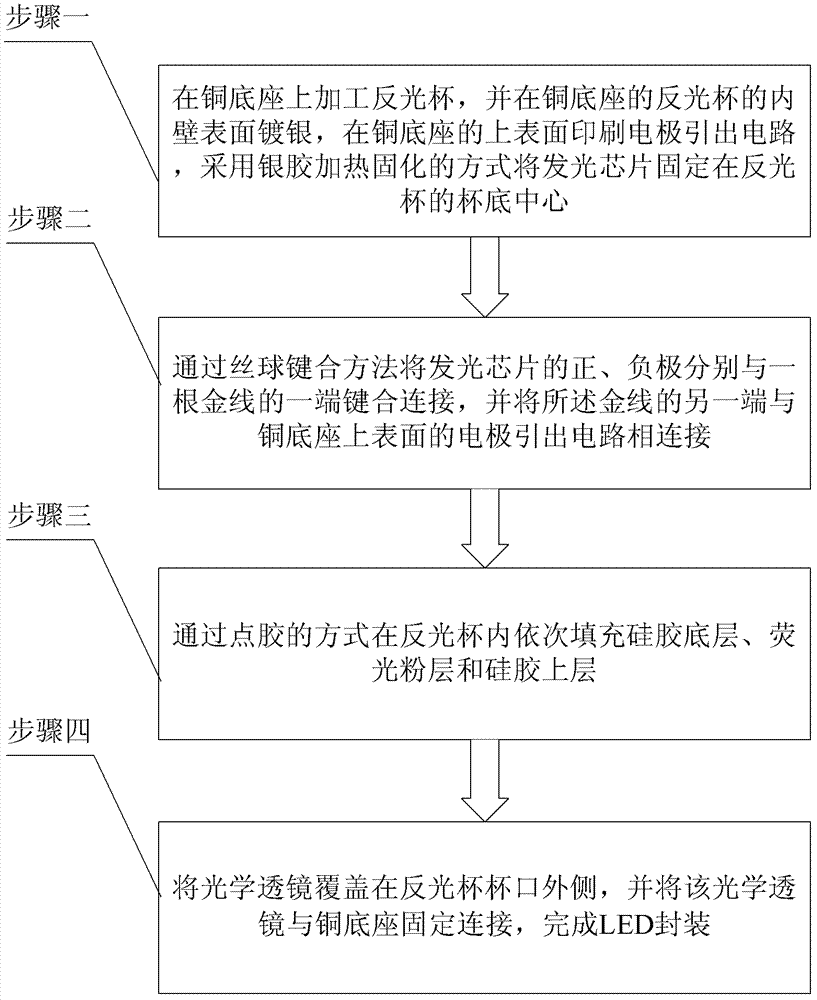

[0028] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode, the white light LED package structure described in this embodiment mode, it comprises copper base 1, light-emitting chip 2, phosphor layer 3 and optical lens 4, it also comprises silica gel bottom layer 5 and silica gel upper layer 6,

[0029] The center of the copper base 1 has a concave reflective cup 1-1, the inner wall surface of the reflective cup 1-1 is plated with silver, the center of the bottom of the reflective cup 1-1 is fixed with the light-emitting chip 2, and the upper surface of the copper base 1 is printed with an electrode lead-out circuit , the positive and negative plates of the light-emitting chip 2 are respectively connected to the electrode lead-out circuit through gold wires for ball bonding,

[0030] The bottom of the reflective cup 1-1 is filled with silica gel bottom layer 5 to fix the light-emitting chip 2, the upper surface of the reflective cu...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment is a further description of Embodiment 1. The light-emitting chip 2 is fixed at the center of the bottom of the reflective cup 1-1 by heating and curing silver glue.

specific Embodiment approach 3

[0034] Embodiment 3: This embodiment is a further description of Embodiment 1 or 2. The electrode lead-out circuit is realized by a printed conductive silver paste layer, and an insulating ink printing layer is between the conductive silver paste layer and the copper base 1 .

[0035] In this embodiment, the conductive silver paste layer is used to realize the electrode lead-out circuit, and the copper base 1 is conducive to better heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com