Urea injection system by adopting gas pressure source

A urea injection system and gas pressure technology, which is applied to the electronic control, exhaust treatment, and exhaust devices of exhaust gas treatment devices, can solve the problem of high energy consumption of batteries, achieve optimal control, and improve measurement accuracy and stability. , the effect of eliminating adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

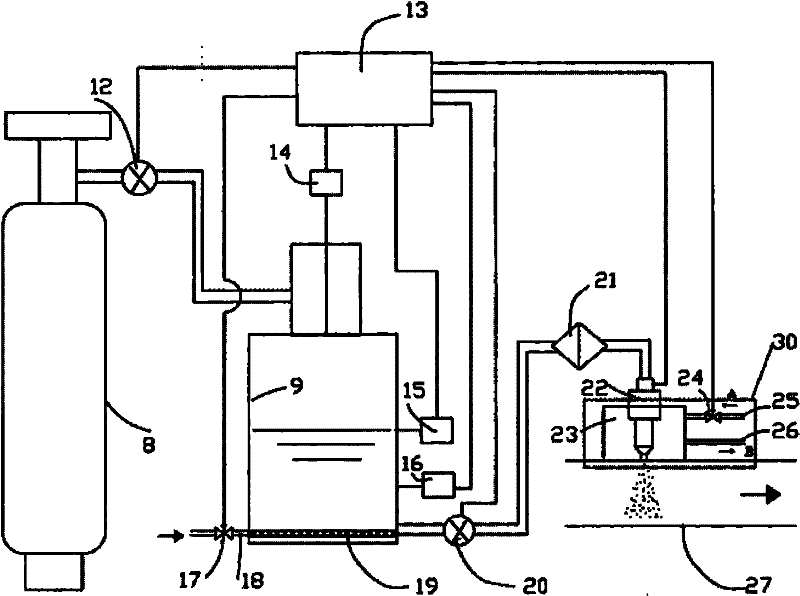

[0014] The invention is a urea injection system using a gas pressure source, wherein the gas pressure source can be a high-pressure gas storage bottle, or an air compressor and a gas storage tank. The first example is figure 1 shown. The high-pressure gas cylinder in this embodiment is a high-pressure nitrogen cylinder 8 with a working pressure of 35MPa. The second example is figure 2 shown. exist figure 2 Among them, a small air compressor is used to inflate the air storage tank 10 through the air charging valve 11 as a gas pressure source. The working pressure is 0.8MPa. The two embodiments have the same working principle except that the gas pressure source is different. The urea solution prepared according to the international standard ISO22241-1 is stored in the urea tank 9 . The urea tank 9 is a pressure vessel, which is pressurized by a gas pressure source, and the volume of the urea tank selected in this embodiment is 40L. Under the effect of pressure, the ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com