SCP urea injection system for post treatment of diesel engine emissions

A urea injection system and exhaust post-treatment technology, which is applied in the direction of exhaust devices, mechanical equipment, engine components, etc., can solve the problems of large fluctuations in the injection volume of urea solution, poor accuracy and stability, etc., and achieve the elimination of adverse effects. Effect of pressure wave in small tube, improving measurement accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

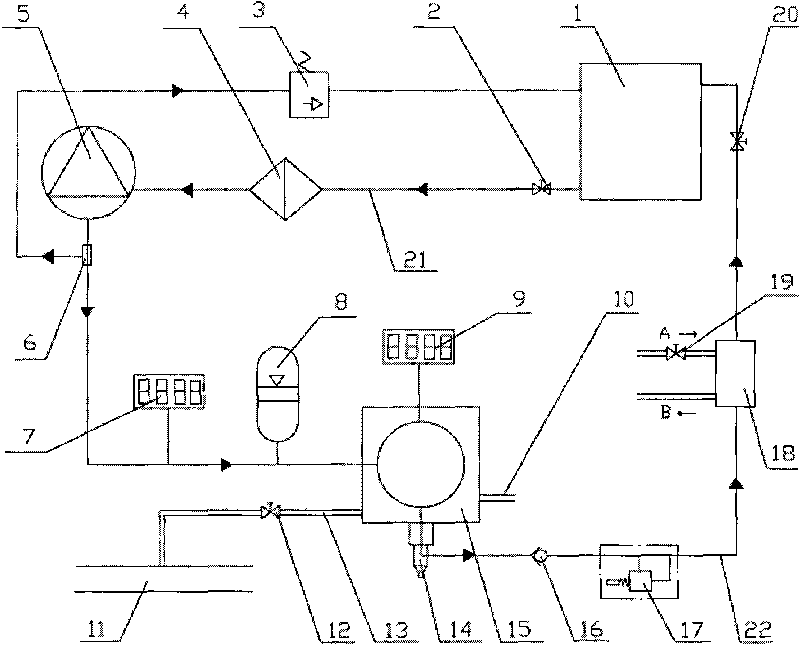

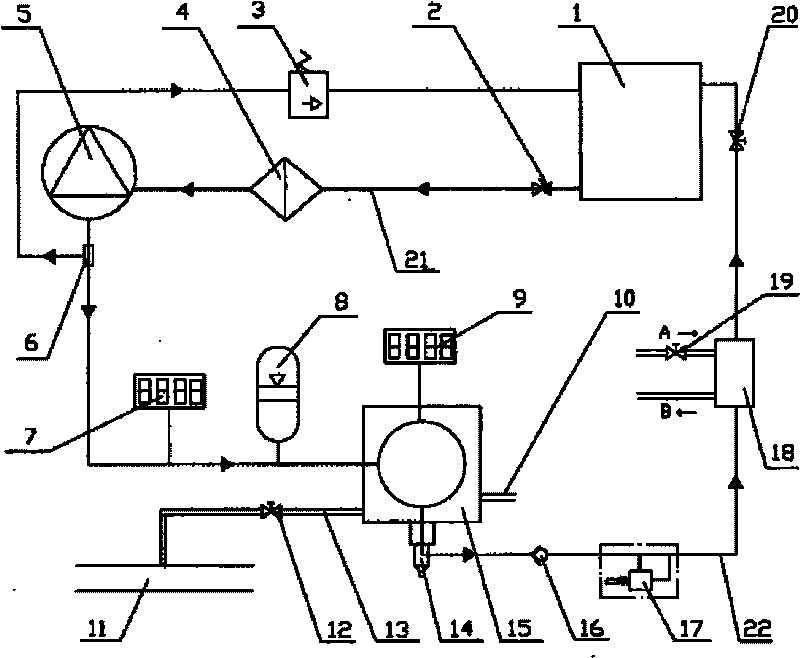

[0014] The SCR urea injection system for diesel engine exhaust aftertreatment according to the present invention, the working principle of its embodiment is as follows figure 1 shown. The urea solution prepared according to the international standard ISO22241-1 is stored in the urea solution tank 1 . The solution flows into the delivery pump 5 through the outlet valve 2 and the filter 4 . The delivery pump 5 adopts a large flow pump, and its flow rate can reach more than 500% of the urea injection volume required by the system. The urea solution supplied by the delivery pump 5 is used as a reducing agent to spray into the exhaust pipe 11 of the diesel engine, and the excess urea solution is used for cooling the urea nozzle 14 . The urea solution used for cooling flows back to the urea solution tank 1 through the one-way valve 16 , the pressure control valve 17 , the return pipe 22 , the cooler 18 and the return valve 20 . The temperature of the urea solution can be adjusted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com