Fabric having antimicrobial odor-eliminating function

A fabric and deodorizing technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of complex fiber development technology processing technology, few types of gases that can be eliminated, and complicated preparation methods, and achieve good water and sweat absorption and durability. Good, simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

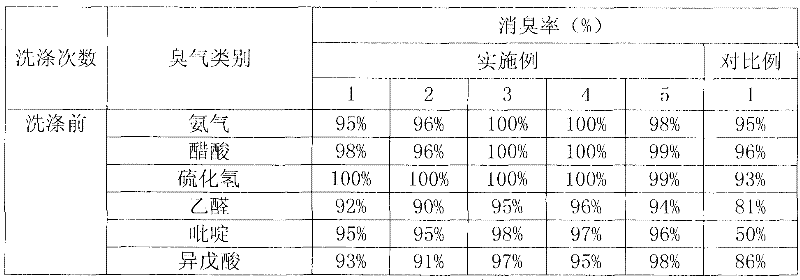

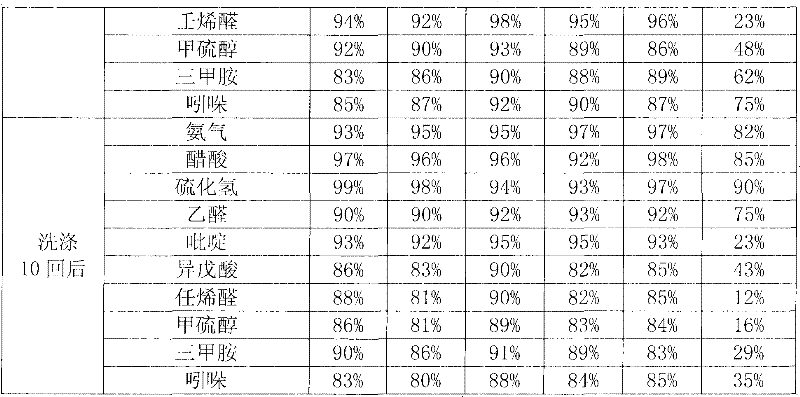

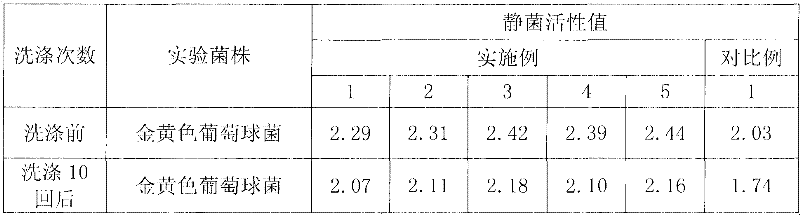

Examples

Embodiment 1

[0059] First prepare the padding working liquid, the working liquid components and parts by weight are as follows:

[0060] Organic antibacterial agent 1-10 parts

[0061] Deodorant composition 10-20 parts

[0062] Adhesive 50 parts

[0063] 100 parts of water

[0064] Among them, the organic antibacterial agent is an organosilicon quaternary ammonium salt antibacterial agent, and the deodorant composition is a deodorant composed of ATOMY BALL (day-volatile chemical catalyst), MEIKAFRESH BSZ (Mingcheng Chemical), and Ti-2000 (Yamato Chemical) according to 2 : the deodorant composition formed in the ratio of 2:1, the adhesive is an acrylic adhesive;

[0065] Then the untreated base fabric is subjected to padding processing (one dipping and one rolling), the drying temperature is 115-130°C, the drying time is 1-3min, the setting temperature is 150-170°C, and the setting time is 0.5-2min. The product is obtained.

Embodiment 2

[0067] First prepare the padding working liquid, the working liquid components and parts by weight are as follows:

[0068] 1-15 parts of organic antibacterial agent

[0069] Deodorant composition 15-25 parts

[0070] Adhesive 50 parts

[0071] 100 parts of water

[0072] Among them, the organic antibacterial agent is an organic silicon quaternary ammonium salt antibacterial agent, and the deodorant composition is a deodorant combination of MEIKAFRESH BSZ (Mingcheng Chemical) and Ti-2000 (Dawa Chemical) in a ratio of 2:3 substance, the adhesive is a silicone adhesive;

[0073] Then the untreated base fabric is subjected to padding processing (two-dipping and two-rolling), the drying temperature is 115-130°C, the drying time is 1-3min, the setting temperature is 150-170°C, and the setting time is 0.5-2min. The product is obtained.

Embodiment 3

[0075] First prepare the coating glue, each component and its parts by weight are as follows:

[0076] Coating resin 100 parts

[0077] Organic antibacterial agent 1-10 parts

[0078] Deodorant composition 5-10 parts

[0079] Wherein the coating resin is polyurethane resin, the organic antibacterial agent is organosilicon quaternary ammonium salt antibacterial agent, and the deodorant composition is composed of ATOMY BALL (Day Volatile Synthetic Catalyst), MEIKAFRESHBSZ (Mingcheng Chemical), Ti-2000 (Yamato Chemical ) deodorant composition in a ratio of 2:2:1;

[0080] Then, the water-repellent-treated base cloth was coated with a knife lift of 400 microns, a drying temperature of 100° C., and a drying time of 5 minutes to finally obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com