Fiber stretching device

A fiber spreading roller and driving device technology, applied in the field of warp knitting, can solve the problems of dry filaments or air bubbles, affecting the board, etc., and achieve the effect of strengthening, preventing breakage, and preventing chain movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

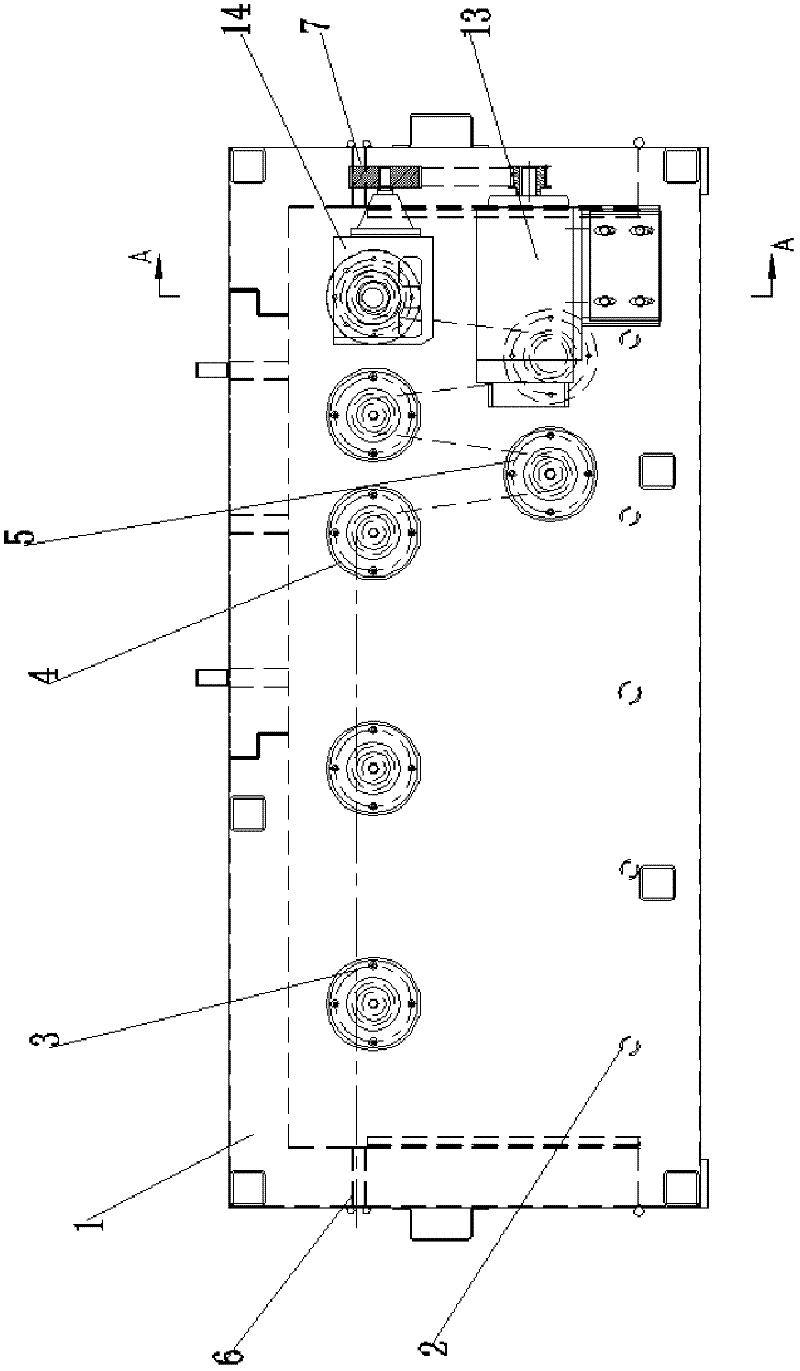

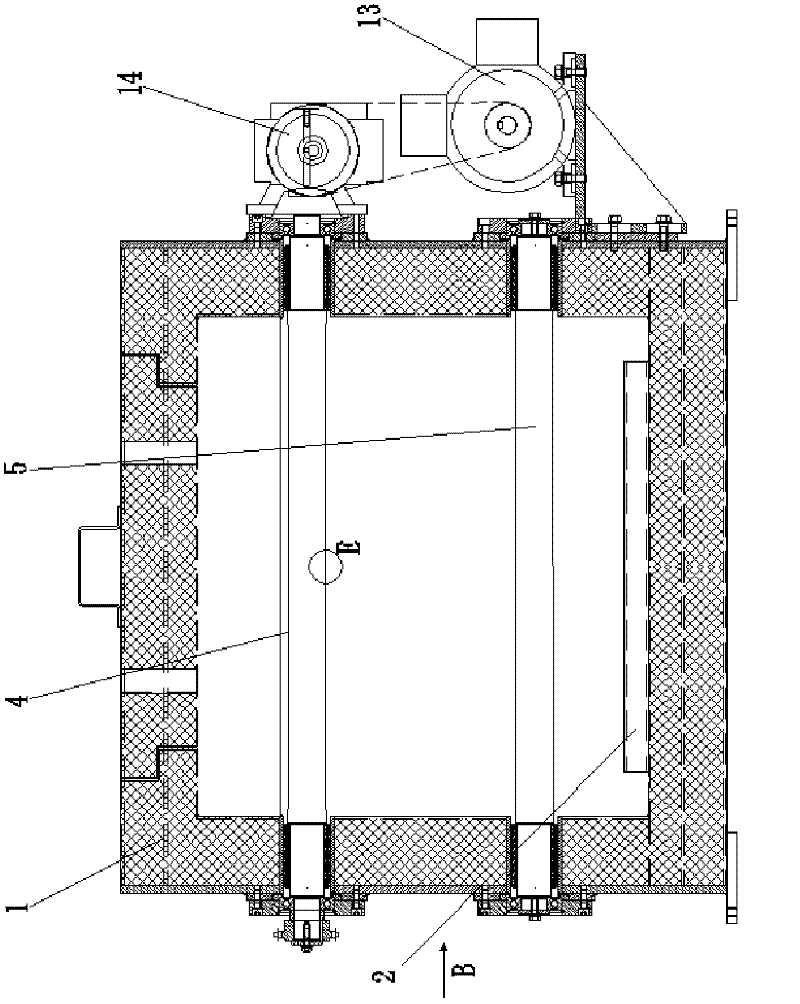

[0018] refer to Figure 1 to Figure 4 A fiber spreading device shown, which includes an oven, a heater arranged in the oven, a guide roller, a fiber spreading roller group and a driving device for driving the fiber spreading roller group arranged outside the oven, on the oven A fiber bundle inlet and a fiber outlet are provided, the guide roller is arranged inside the fiber bundle inlet, and the fiber spreading roller group is arranged inside the fiber outlet, and the fiber spreading roller group includes an active fiber spreading roller and a driven fiber spreading roller, and the active fiber spreading roller The surface of the roller is provided with an arc convex surface, and the driven fiber spreading roller is cylindrical with a smooth surface, and the driven fiber spreading roller is arranged under the active fiber spreading roller.

Embodiment 2

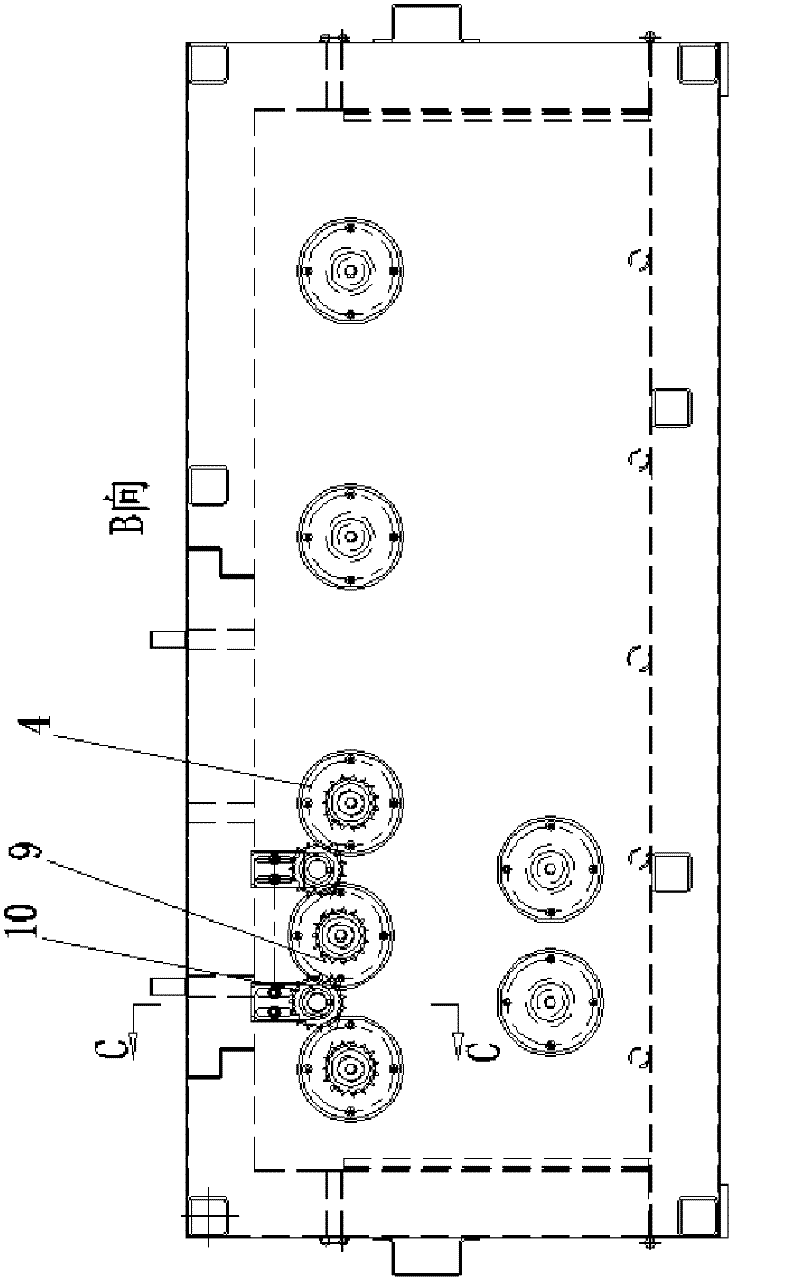

[0020] As a further improvement of the technical solution of the present invention, on the basis of Example 1, in order to make each fiber spreading roller rotate synchronously and ensure that the tension of the fiber is uniform, the described fiber spreading roller group includes a plurality of active fiber spreading rollers, all active The fiber spreading roller is driven by the same chain, and a pinch wheel to prevent the chain from moving is arranged above the chain, and the pinch wheel shaft of the pinch wheel is arranged on the pinch wheel support.

[0021] As a further improvement of the technical solution of the present invention, on the basis of Example 1, in order to control the speed of fiber spreading and improve the effect of fiber spreading, the drive device includes a motor, a reducer connected to the output shaft of the motor through a belt, and the speed reduction The output shaft of the machine is connected with the active spreading roller.

[0022] As a furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com