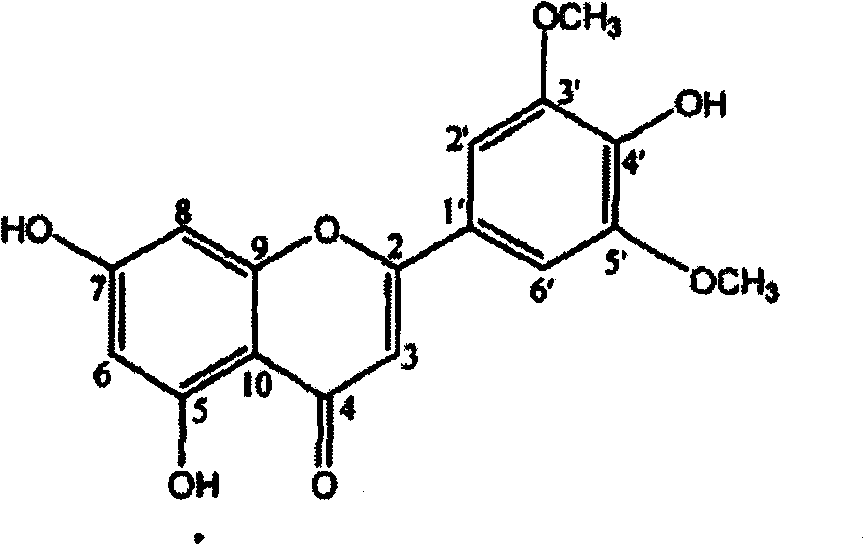

Preparation method of tricin

A technology of alfalfa and alfalfa, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of long preparation period, less preparation amount, and large amount of solvent usage, and achieve large processing capacity, easy operation, and high purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Get 1kg of alfalfa, crush it, add it to the extraction kettle, and use supercritical CO 2 For extraction, set the conditions of the extraction kettle as follows: the extraction temperature is 40°C, the extraction pressure is 25MPa, CO 2 The flow rate is 15L / h, the extraction time is 2.5h, and 100ml of ethanol is introduced as an entrainer to participate in the extraction. The conditions of the separation tank are set as follows: the temperature of the separation tank I is 30 ° C, the pressure is 8 MPa, the temperature of the separation tank II is 22 ° C, the pressure 5MPa, collect the alfalfa extract in the separation kettle II, dissolve it with an appropriate amount of ethanol, add 350g polyamide resin (80 mesh) to mix the sample, evaporate the solvent, pack the column, wash with 2BV water to remove impurities, and then use 3BV containing 1 90% ethanol solution of % hydrochloric acid was used for elution, the eluate was collected, concentrated to a small volume, left t...

Embodiment 2

[0023] Get 10kg of alfalfa, pulverize, add in the extraction kettle, adopt supercritical CO 2 For extraction, set the conditions of the extraction kettle as follows: the extraction temperature is 55°C, the extraction pressure is 35MPa, CO 2 The flow rate is 30L / h, the extraction time is 1h, and 2L of methanol is introduced as an entrainer to participate in the extraction. The conditions of the separation tank are set as follows: the temperature of the separation tank I is 40°C, the pressure is 10MPa, the temperature of the separation tank II is 30°C, and the pressure is 8MPa, collect the alfalfa extract in the separation kettle II, dissolve it with an appropriate amount of ethanol, add 6kg polyamide resin (120 mesh) to mix the sample, evaporate the solvent, pack the column, first wash away the impurities with 3BV water, and then use 7BV containing 1% The 70% ethanol solution of hydrochloric acid was eluted, the eluate was collected, concentrated to a small volume, left to crys...

Embodiment 3

[0025] Get 20kg of alfalfa, pulverize, add in the extraction kettle, adopt supercritical CO 2 For extraction, set the conditions of the extraction kettle as follows: the extraction temperature is 45°C, the extraction pressure is 30MPa, CO 2 The flow rate is 25L / h, the extraction time is 2h, and 3L of ethanol is introduced as an entrainer to participate in the extraction. The conditions of the separation tank are set as follows: the temperature of the separation tank I is 35°C, the pressure is 9MPa, the temperature of the separation tank II is 25°C, and the pressure is 6MPa, collect the alfalfa extract in the separation kettle II, dissolve it with an appropriate amount of ethanol, add 8kg polyamide resin (200 mesh) to mix the sample, evaporate the solvent, pack the column, first wash away the impurities with 4BV water, and then use 6BV containing 1% The 85% ethanol solution of hydrochloric acid was eluted, the eluent was collected, concentrated to a small volume, left to crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com