Intelligent temperature-control vanadium dioxide composite multifunctional thin film and preparation method thereof

A nano-composite and composite film technology, applied in the field of VO2 nano-composite films, can solve problems such as impact and low light transmittance, and achieve the effect of improving the transmittance in the visible light region and good infrared thermal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] with V 2 o 5 Powder, benzyl alcohol and isopropanol were mixed at a molar ratio of 1:4:50, and stirred at 80°C for 2 hours to prepare a vanadium precursor; VO x Thin film (2.02 / Ar mixed atmosphere (hydrogen volume content 4%) for 3 hours, after natural cooling, crystallized VO can be formed 2film. SiO was prepared by sol-gel technique using analytically pure ethyl orthosilicate, absolute ethanol, ammonia and deionized water at a volume ratio of 1:10:0.2-0.5:0.1 2 Precursor sol; by pulling coating technology (speed is 50mm / min), prepare VO 2 / SiO 2 composite film, and then dried at 100°C for 10 min to obtain the desired VO 2 / SiO 2 nanocomposite films.

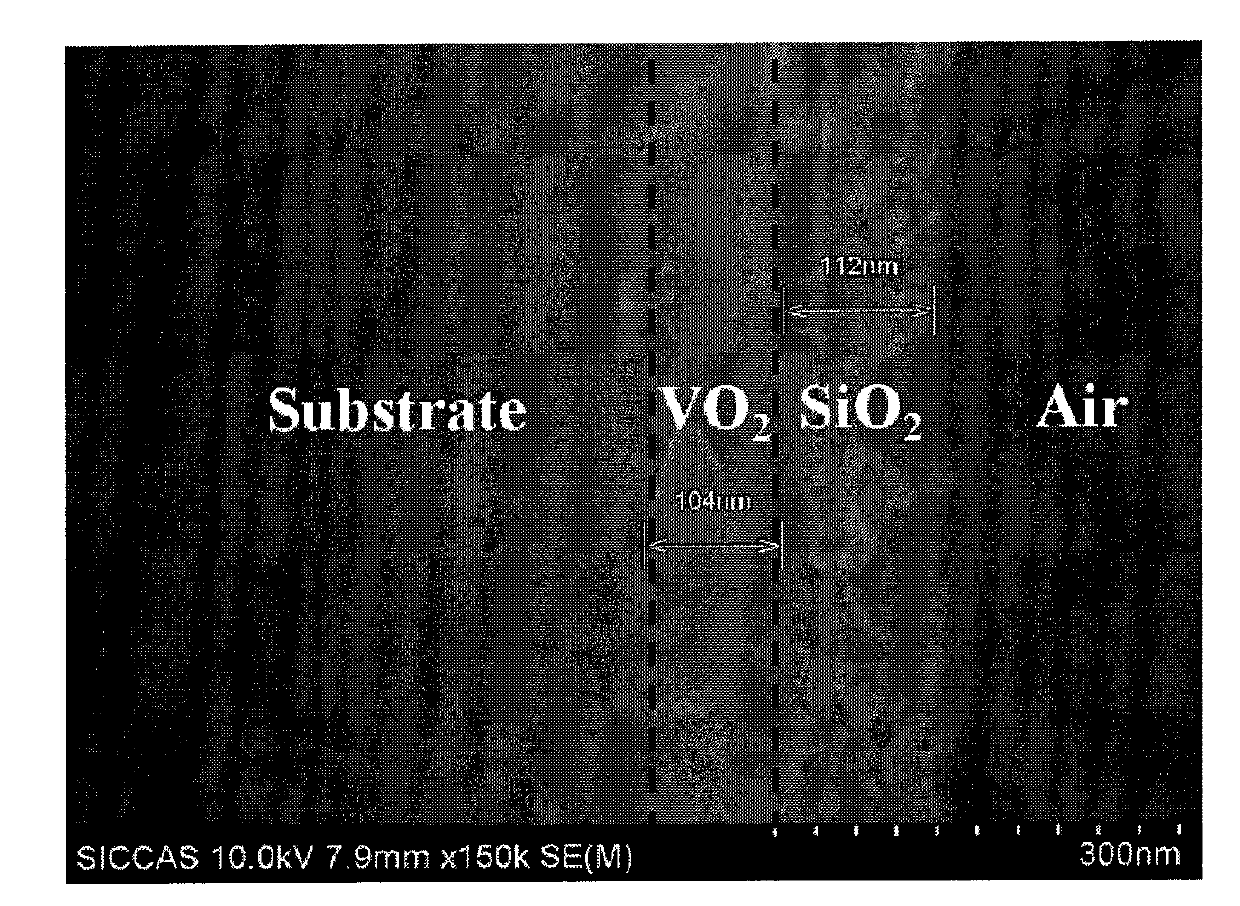

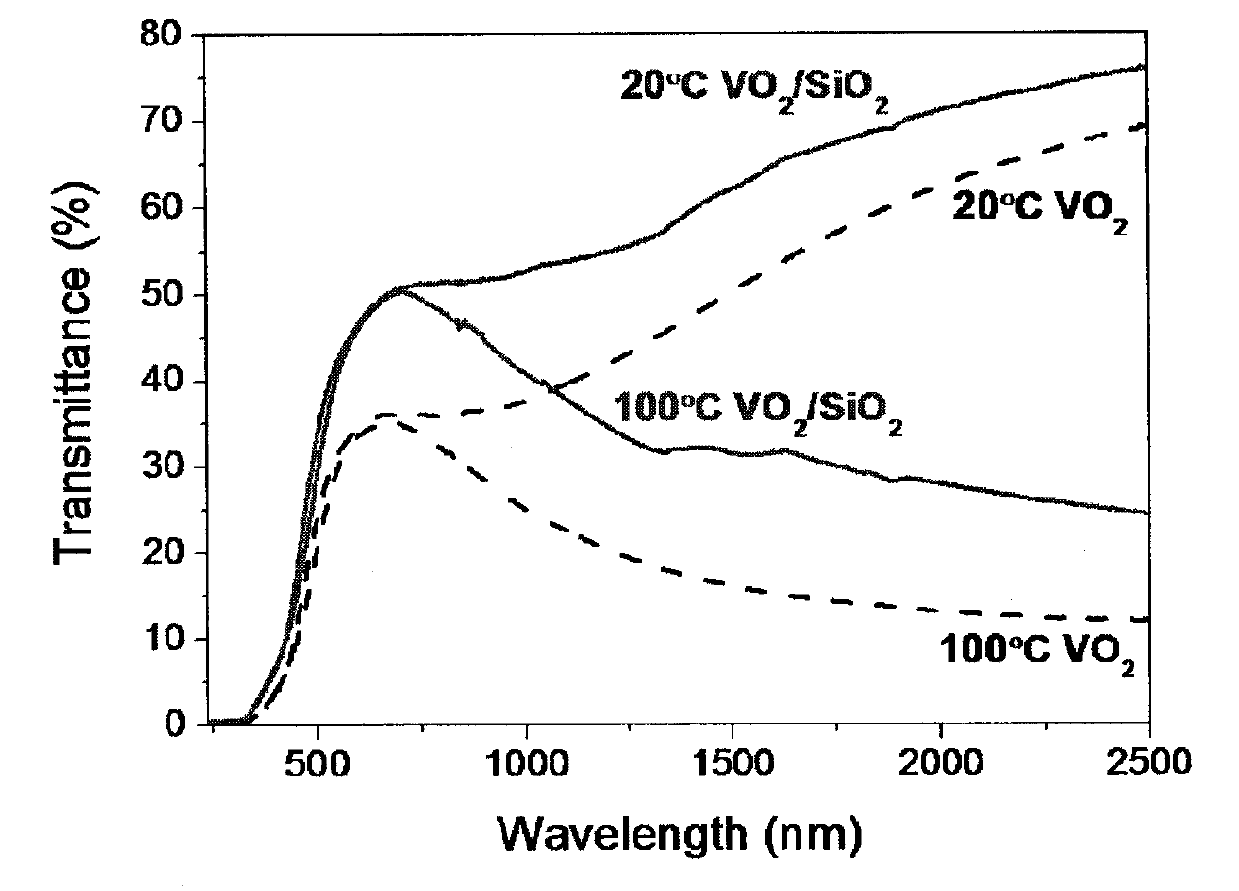

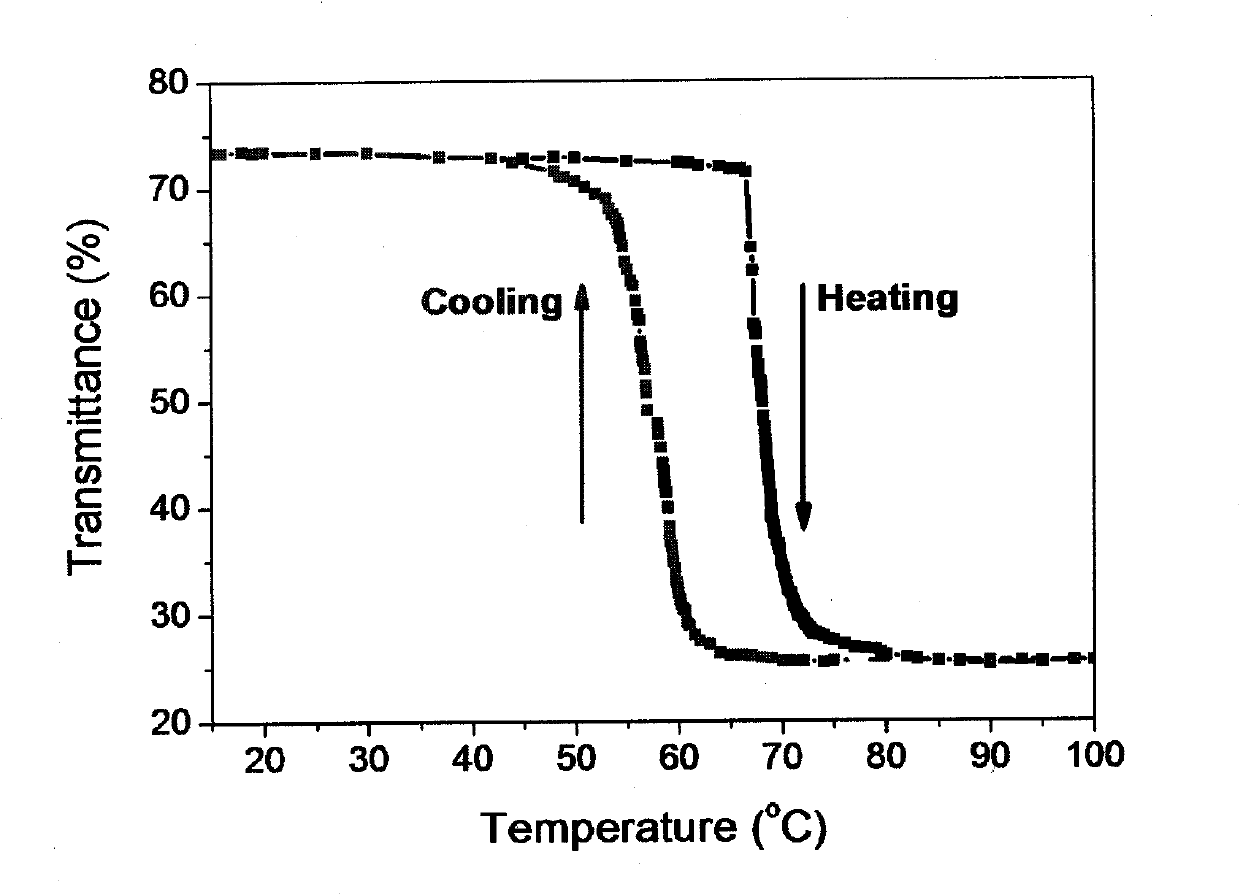

[0029] figure 1 Corresponding to VO 2 / SiO 2 SEM image of surface morphology of nanocomposite film, substrate / VO 2 、VO 2 / SiO 2 and SiO 2 There is a clear boundary between / air, which is marked by a black dotted line in the figure, SiO 2 Particle size is 20-50nm, VO 2 The grain size distribution is in ...

Embodiment 2

[0032] with V 2 o 5 Powder, benzyl alcohol and isopropanol were mixed in a molar ratio of 1:4:50, stirred at 80°C for 5 hours, and prepared by spin-coating coating technology (at a speed of 3000r / min). x Thin film (2.02 / Ar mixed atmosphere (hydrogen volume content 4%) for 3 hours, after natural cooling, crystallized VO can be formed 2 film. SiO was prepared by sol-gel technique using analytically pure ethyl orthosilicate, absolute ethanol, ammonia and deionized water at a volume ratio of 1:10:0.2-0.5:0.1 2 The precursor sol; By spin coating technology (speed is 3000r / min), prepare VO 2 nanocomposite film, and then dried at 100°C for 10 min to obtain the desired VO 2 / SiO 2 nanocomposite films. All the other are with embodiment 1.

Embodiment 3

[0034] with V 2 o 5 The powder, benzyl alcohol and isopropanol were mixed at a molar ratio of 1:4:50, and stirred at 80°C for 2 hours; at the same time, by sol-gel technique, analytically pure tetraethyl orthosilicate, absolute ethanol , ammonia water and deionized water, according to the volume ratio of 1:10:0.2-0.5:0.1 to prepare SiO 2 The precursor sol, and then under stirring conditions at room temperature, to obtain VO x -SiO 2 (2.0x -SiO 2 nanocomposite film, then at 410°C, H 2 / Ar mixed atmosphere (hydrogen volume content 4%) for 3 hours, after natural cooling, crystallized VO can be formed 2 -SiO 2 nanocomposite films. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com