Preparation method of ginkgo leaf extract

A technology of Ginkgo biloba leaves and extract, applied in the field of preparation of Ginkgo biloba extract, can solve problems such as low product yield and unstable quality, and achieve the effects of improving quality and grade, improving production efficiency and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

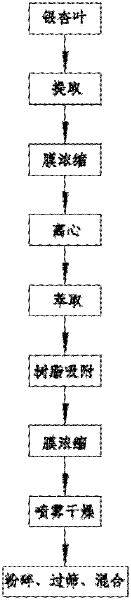

[0031] Such as figure 1 Shown, the preparation method of the Ginkgo biloba extract described in this embodiment, its steps are as follows:

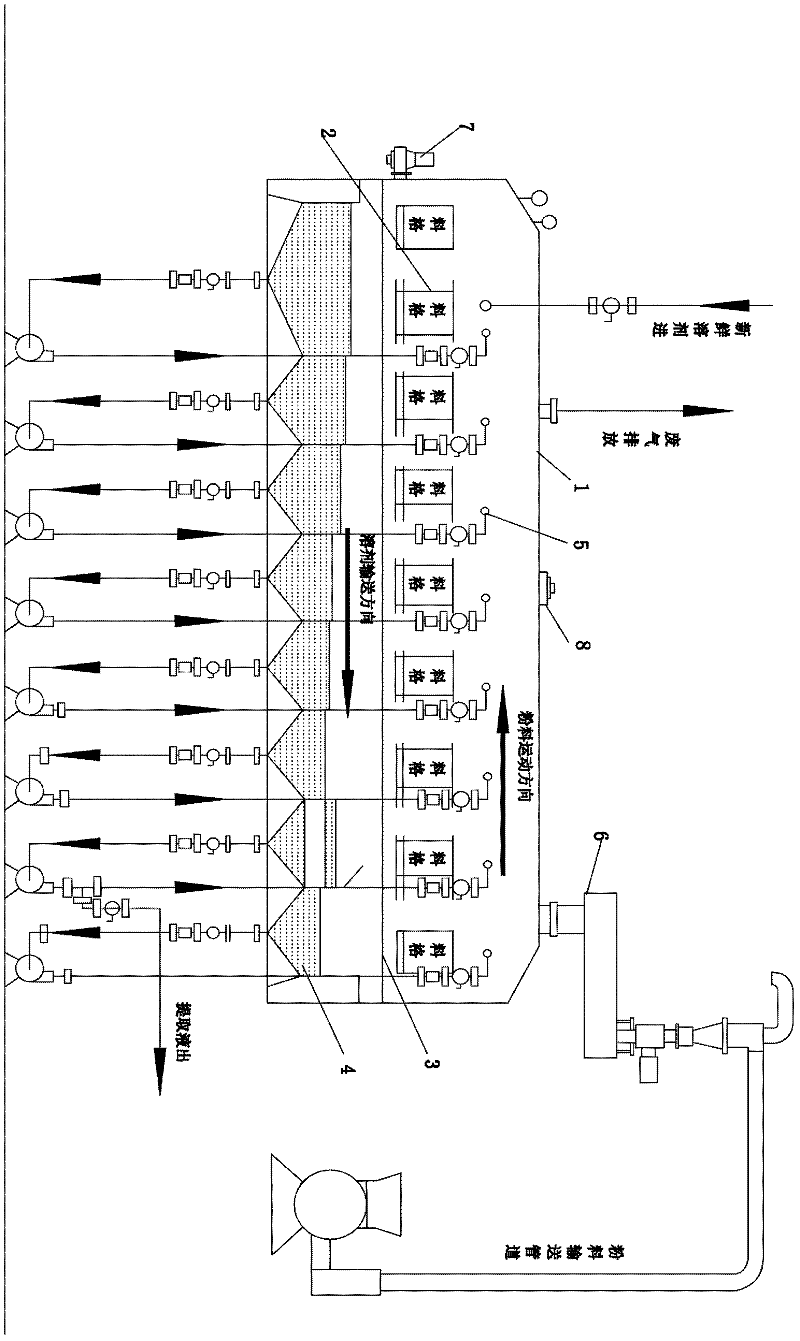

[0032] (1) Extraction step: 2 tons of ginkgo leaves are continuously dropped into the pulverizer to pulverize at a speed of 200kg / h-260kg / h, and are extracted with reverse gradient continuous extraction equipment. What the extraction solvent adopts is ethanol of 60% concentration, the flow rate of solvent 1.8M per hour 3 -2.0M 3 Put it into this equipment, the temperature is controlled at 40°C-70°C, and filter after the extraction is completed;

[0033] (2) Concentration step: Concentrate the filtrate through a thin film evaporator, control the flow rate at 2000L / h-3000L / h, and control the temperature at 60°C-90°C;

[0034] (3) centrifugation step: the concentrated solution is centrifuged by a centrifugal device with a separation factor above 3000;

[0035] (4) Extraction step: extract the concentrated solution after centrifugation wi...

Embodiment 2

[0040] The preparation method of the Ginkgo biloba extract described in this embodiment, its steps are as follows:

[0041] (1) Extraction step: 2 tons of ginkgo leaves are continuously dropped into pulverizer to pulverize at a speed of 200kg / h-260kg / h, and are extracted with reverse gradient continuous extraction equipment. What the extraction solvent adopts is acetone of 60% concentration, and the temperature is controlled at 40°C-70°C, filter after extraction;

[0042] (2) Concentration step: Concentrate the filtrate through a thin film evaporator, control the flow rate at 2000L / h-3000L / h, and control the temperature at 60°C-90°C;

[0043] (3) centrifugation step: the concentrated solution is centrifuged by a centrifugal device with a separation factor above 3000;

[0044] (4) Extraction step: extract the concentrated solution after centrifugation with acetone and butanone mixed solution, the mixing ratio of acetone and butanone is: acetone: butanone=1:1;

[0045] (5) Res...

Embodiment 3

[0049] The preparation method of the Ginkgo biloba extract described in this embodiment, its steps are as follows:

[0050] (1) Extraction step: 2 tons of ginkgo leaves are continuously dropped into the pulverizer to pulverize at a speed of 200kg / h-260kg / h, and are extracted with reverse gradient continuous extraction equipment. What the extraction solvent adopts is ethanol of 60% concentration, and the temperature is controlled at 40°C-70°C, filter after extraction;

[0051](2) Concentration step: Concentrate the filtrate through a thin film evaporator, control the flow rate at 2000-3000L / h, and control the temperature at 60°C-90°C;

[0052] (3) centrifugation step: the concentrated solution is centrifuged by a centrifugal device with a separation factor above 3000;

[0053] (4) Extraction step: extract the concentrated solution after centrifugation with a mixed solution of acetone and butanone, the mixing ratio of acetone and butanone is: acetone: butanone=1: 0.9;

[0054]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com