Method for providing an identifiable powder volume and method for producing an object

A powder and object technology, applied in the field of laser sintering to manufacture three-dimensional objects, can solve the problems of time-consuming and inappropriate, and achieve the effect of ensuring reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

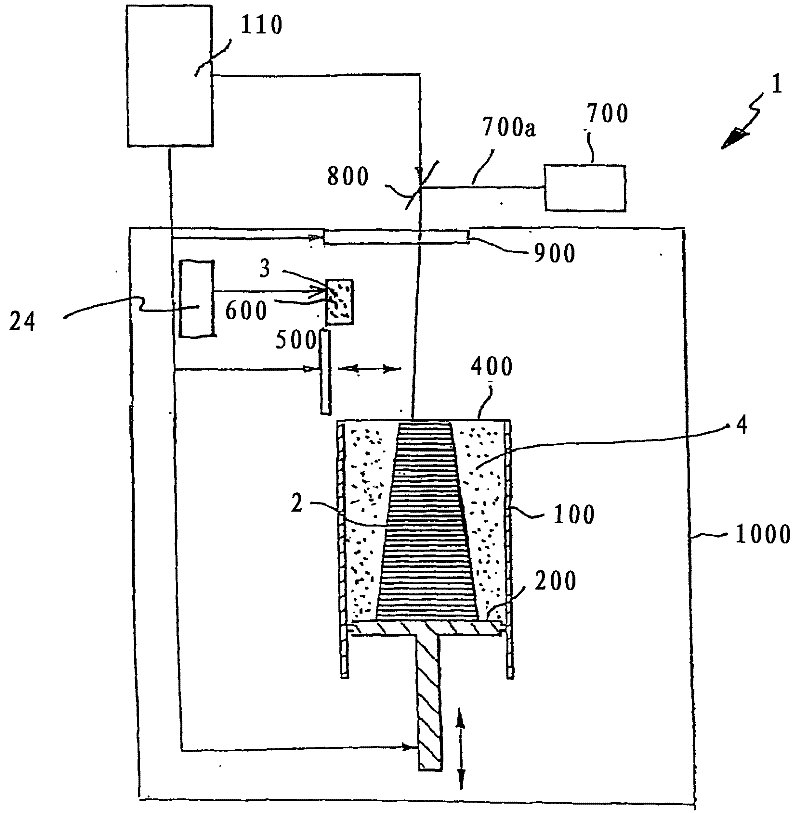

[0016] First, the first embodiment will be described below by taking laser sintering as an example with reference to the drawings.

[0017] figure 1 The laser sintering equipment 1 exemplarily shown in includes an upwardly opening construction chamber 100 , in which a vertically displaceable carriage 200 is located, which carries the object 2 to be constructed and delimits the construction area. The carriage 200 is arranged vertically such that the respective layer to be hardened of the object 2 is located in the working surface 400 . Furthermore, an application device 500 is provided for applying a powder 3 which is curable by electromagnetic radiation. The powder 3 is fed in a certain amount from the storage container 24 to the application device 500 via a metering device 600 . In addition, a laser 700 is provided which generates a laser beam 700 a which is deflected by a deflection device 800 onto an input window 900 from which it enters the processing chamber 1000 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com