Ion implantation system and method

An ion implantation system and ion implantation technology, which are applied in the field of ion implantation systems, can solve problems such as design difficulties, and achieve the effects of convenient installation and debugging, ensuring implantation quality and reducing design size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

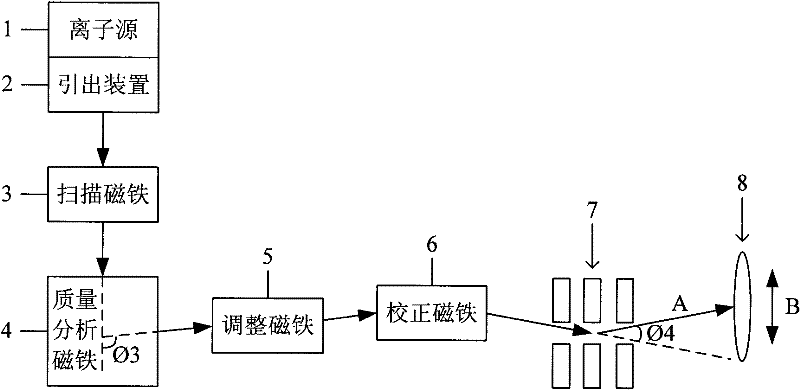

[0043] When the ion implantation system of the present invention is used to perform high-energy ion implantation, the figure 1 The shown beam transmission path transmits the ion beam to the implantation station, so as to finally complete the ion implantation process on the workpiece.

[0044] First, an ion beam is extracted from the ion source 1 by the extraction device 2 . Then pass through the scanning magnet 3 in the figure 1 The ion beam is scanned in a direction perpendicular to the paper, so that the ion beam forms a distribution in the scanning direction. Next, the ion beam passes through the mass analysis magnet 4 and is deflected by the mass analysis magnet 4 In this way, only ions suitable for implantation with energies within a preset range of charge-to-mass ratio remain in the beam after passing through the mass analysis magnet 4 . Wherein, in particular, the operating parameters of the mass analysis magnet 4 are set to: make the angle relatively small (less ...

Embodiment 2

[0046] When the ion implantation system of the present invention is used to perform low-energy ion implantation, the figure 2 The shown beam transmission path transmits the ion beam to the implantation station, so as to finally complete the ion implantation process on the workpiece.

[0047] The only difference between the system in this embodiment and the system in Embodiment 1 is: at this time, the mass analysis magnet 4 performs a relatively large deflection angle on the beam current (more than the figure 1 middle ), that is, the beam current is deflected to cross the entrance of the speed change device 7, correspondingly, when the beam current reaches the correcting magnet 6, the beam current is deflected back to the direction aligned with the entrance of the speed change device 7 by the correction magnet 6. This rectifying magnet 6 that has correction and deflection effect simultaneously can utilize the magnet device of various existing structures to realize, but pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com