Heat-resistant lining structure of tunnel with high ground temperature

A high ground temperature, tunnel technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of reducing structural bearing capacity, affecting structural durability, and rising ambient temperature, so as to ensure permanent support and bearing function, good durability Thermal properties and adaptability, the effect of reducing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

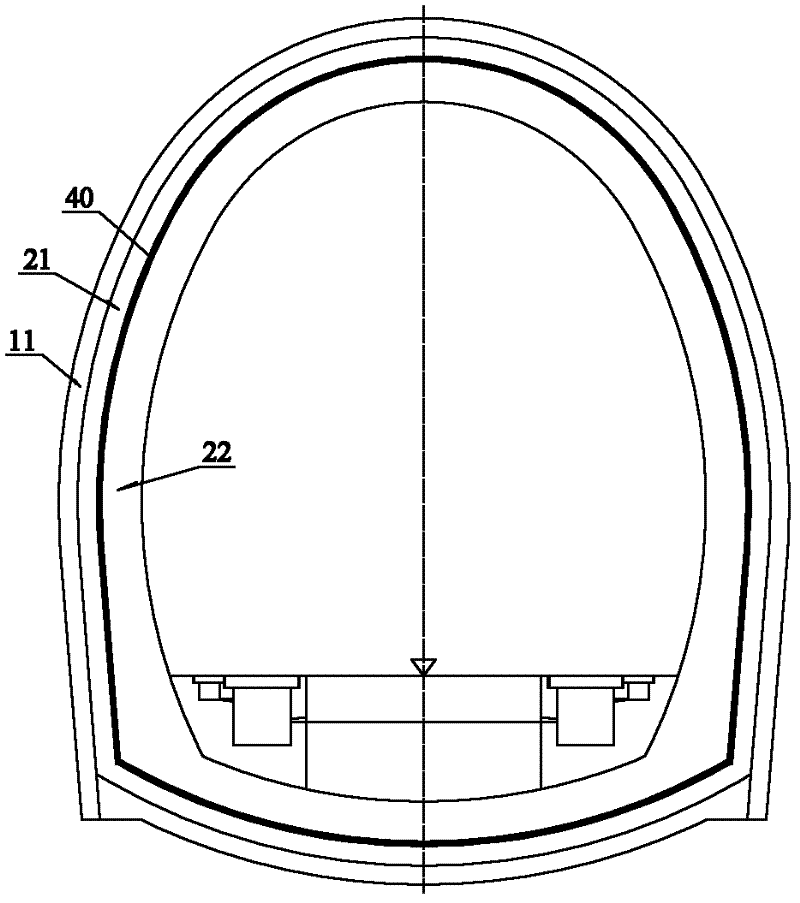

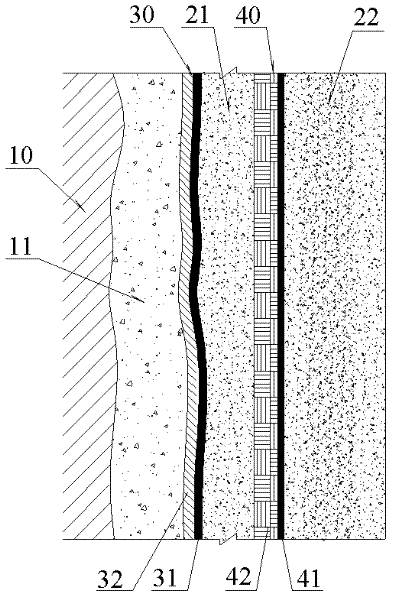

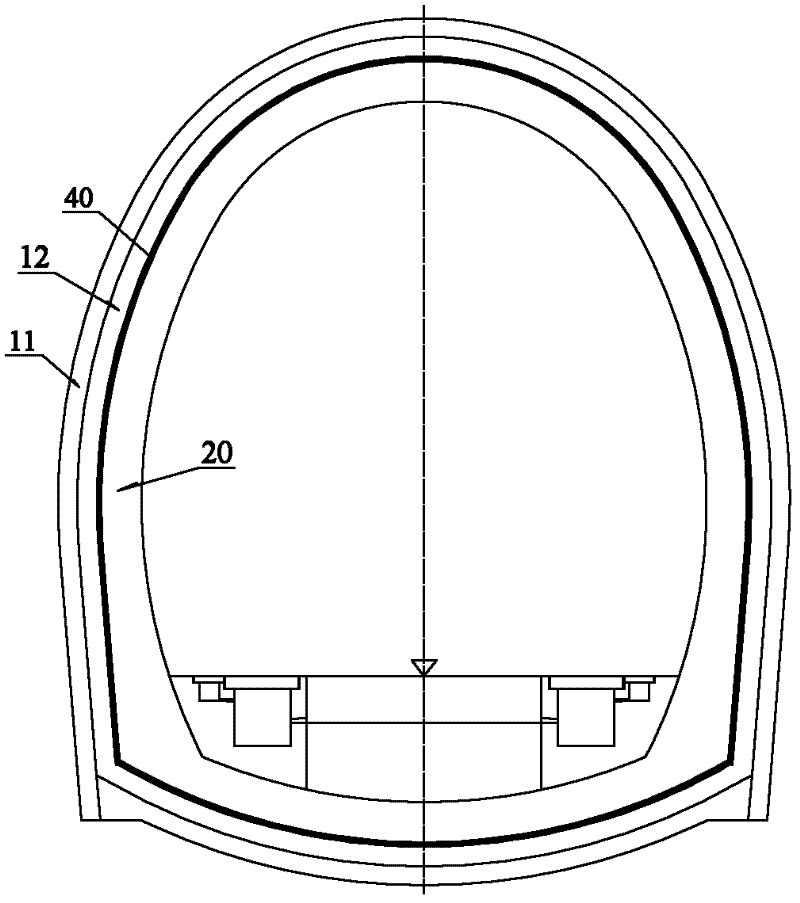

[0019] refer to figure 1 and image 3 , the high ground temperature tunnel heat-resistant lining structure of the present invention includes surrounding rock 10, primary support 11 and secondary lining 20, primary support 11 covers the surface of surrounding rock 10, and secondary lining 20 is built on primary support 11 within. refer to figure 2 and Figure 4 , the initial support 11 is formed by sprayed ceramsite concrete, and a heat insulation layer and a waterproof, drainage and heat insulation composite layer 40 are also arranged inside the initial support 11, and the heat insulation layer is an outer lining formed by molded ceramsite concrete 21 or primary support leveling layer 12. The waterproof, drainage and thermal insulation composite layer 40 is arranged between the outer lining 21 and the inner lining 22 of the secondary lining 20 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com