Method and device for sensible heat reclaiming of blast furnace slag and desulfurization of sintering flue gas

A technology for recovery of sintering flue gas and sensible heat, which is applied in separation methods, recycling technologies, chemical instruments and methods, etc., and can solve problems such as deteriorating working environment, unusable sensible heat of blast furnace slag, air, water and soil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

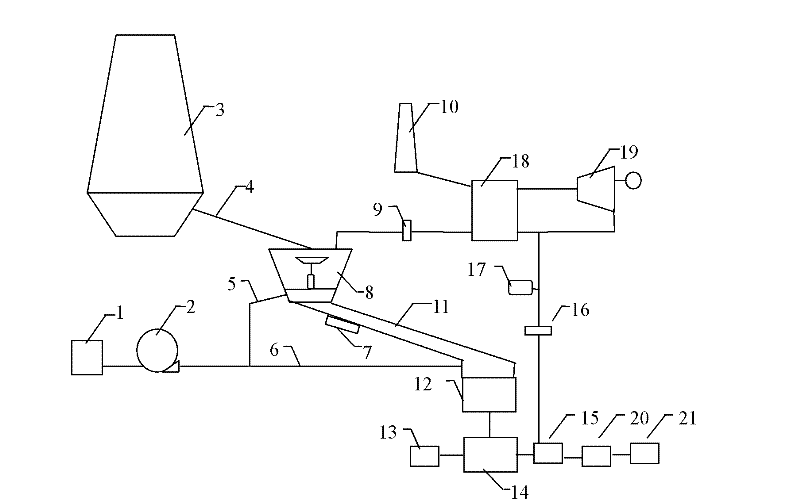

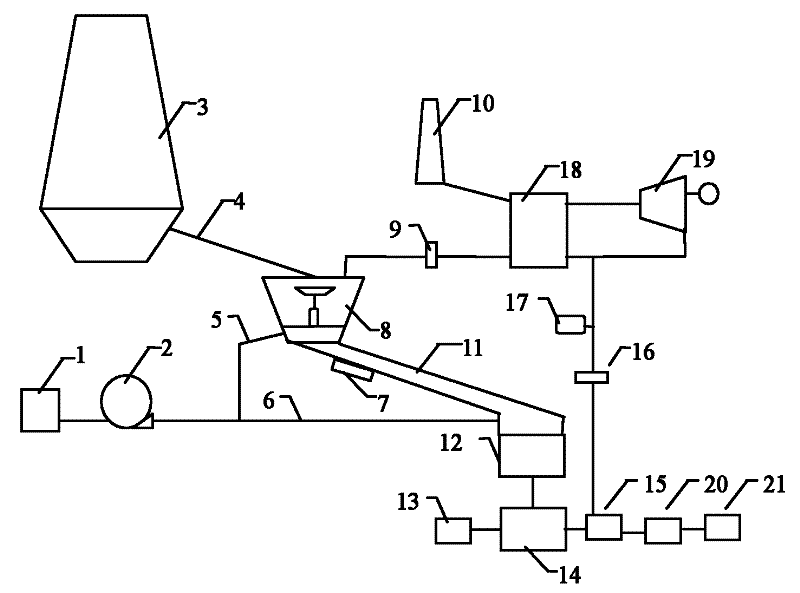

[0018] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0019] See figure 1 , is a schematic flow chart of the embodiment of the method for recovering sensible heat from blast furnace slag while desulfurizing sintering flue gas in the present invention. The molten blast furnace slag is crushed in the granulation reactor 8 and then undergoes the initial desulfurization reaction and the first sintering flue gas from the sintering waste heat boiler 1. The first heat exchange, and then the second desulfurization reaction and the second recovery of heat through the vibrating bed 11, and finally the third recovery of heat in the cooling pool 12, the recovered heat can be reused in the form of power generation, blast furnace slag and desulfurization The products are used to make cement and gypsum respectively, and the steps of its realization are as follows:

[0020] 1) The molten blast furnace slag with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com