System and method for recycling calcium carbide liquid sensible heat

A calcium carbide and liquid display technology, applied in the chemical industry, can solve the problems such as insufficient development and utilization of sensible heat, and achieve the effect of effective recycling, avoiding high temperature oxidation and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

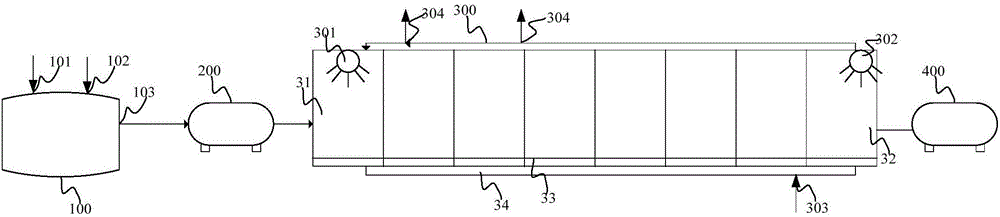

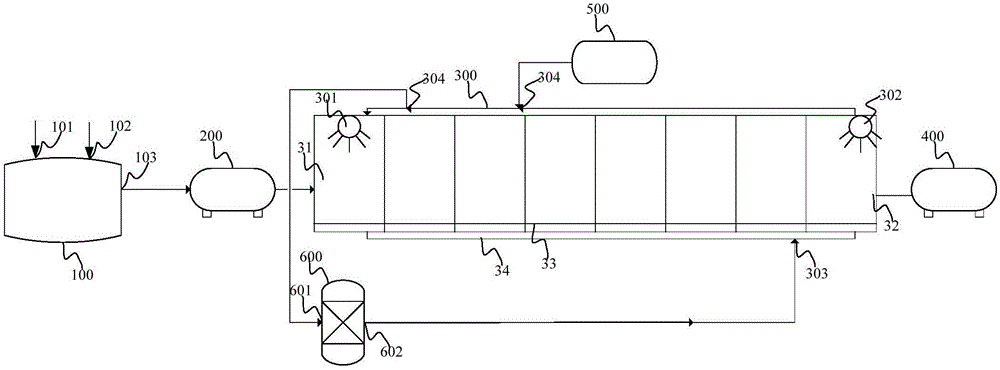

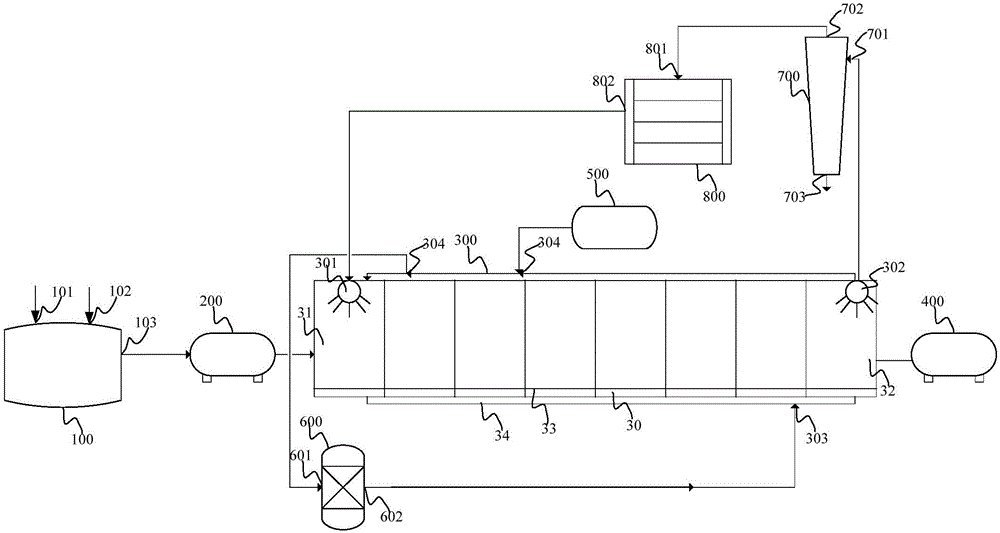

[0082] Coke and calcium oxide are supplied to the calcium carbide furnace at a mass ratio of 0.75:1 for electrothermal reaction at 1800-2200°C to obtain calcium carbide liquid at about 2000°C, and then the reacted calcium carbide liquid is transferred to the calcium carbide car, and then The calcium carbide cart is pushed into a tunnel kiln with a furnace width of 1500mm, a furnace height of 1400mm, and a furnace length of 100m by a hydraulic drive device. Automatically opened and closed cast iron furnace doors are set at the kiln head and kiln tail, and vertical tubes are arranged on the vertical side walls on both sides of the furnace. Water-cooled wall, the bottom of each water-cooled wall is equipped with a horizontal water distribution pipe to connect with the forced circulation water pump, and the top is equipped with a horizontal water-collecting pipe to connect with the steam drum and the cooling water tower respectively, and is suitable for supplying part of the hot wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com