Carburized bearing steel for high-speed railways and preparation method thereof

A carburizing bearing and high-speed railway technology, applied in the field of railway steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

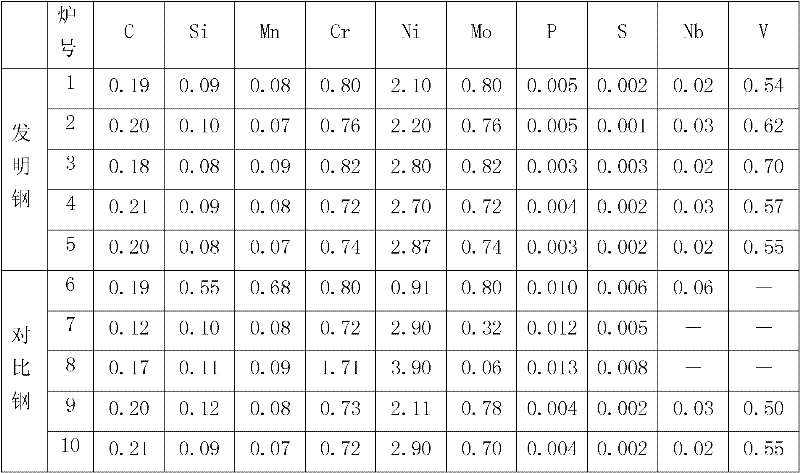

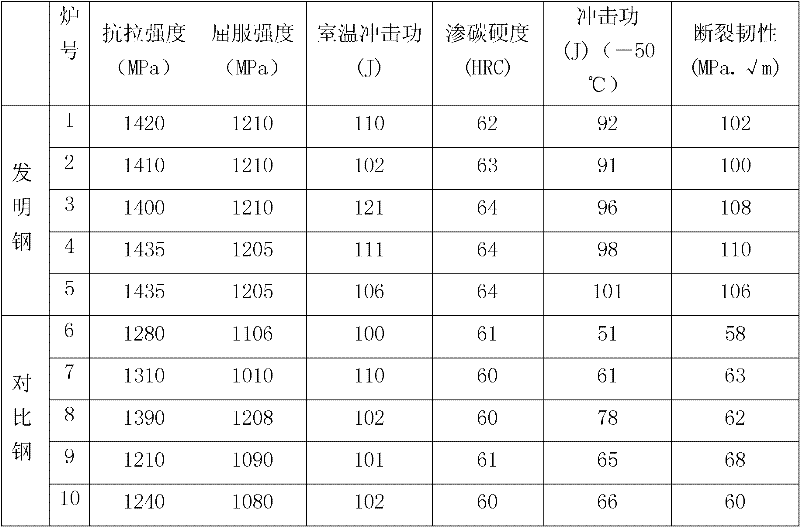

[0027]According to the chemical composition range designed by the present invention, 5 furnaces (furnace number 1~5) of invention steel and 5 furnaces of contrast steel (furnace number 6~10) were smelted on 400kg vacuum induction furnace and vacuum consumable furnace. The composition is shown in Table 1. The chemical composition of the invented steel (furnace No. 1-5) is basically the same, and its Ni content varies in the range of 2-3%. V, only 0.06% Nb is added, No. 7 and No. 8 comparative steels have higher S and P, and no V and Nb microalloying elements are added, and No. 8 comparative steel has higher Cr and Ni alloying elements. The steel is vacuum smelted, poured into ingots, forged and billeted, and rolled into Φ120 bars. The starting forging temperature is 1050°C, and the final forging temperature is 880°C. Annealed at 600°C after hot working. Sampling and processing into standard room temperature tensile specimens, Charpy notch impact specimens, hardness specimens,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com