High-efficient liquefied petroleum gas and preparation method thereof

A liquefied petroleum gas, high-efficiency technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve problems such as incomplete combustion, environmental pollution, high-pressure explosion, etc., and achieve high content of activated gasification substances, simple preparation method, and wide range of applications broad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

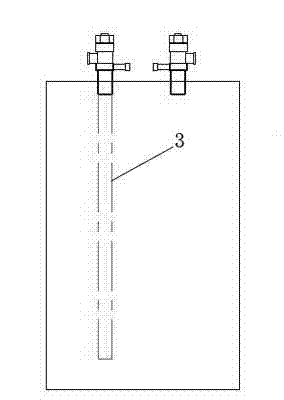

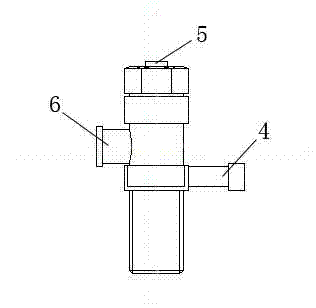

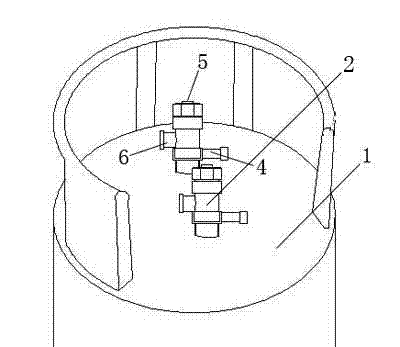

[0011] Transport 5,000 grams of steel cylinder 1 with a volume of 12 liters to the gas filling station to fill with 1,500 grams of mother liquor (the mother liquor is liquefied petroleum gas), and use a plastic spoon to put 0.6 grams of catalyst copper oxide powder into the drain on the angle valve 2 on the top of the cylinder. At gas port 6, connect a special filling gun and open the safety valve 4 of the steel cylinder, inject 80 grams of petroleum ether into steel cylinder 1 with a liquid filling gun (the catalyst follows into it), and then inject 800 grams of hydrogen peroxide into steel cylinder 1. At 0°C, 3% antifreeze ethanol needs to be added, and the safety valve 4 is closed to obtain 2380.6 grams of the required "high-efficiency liquefied petroleum gas", such as Figure 1-3 As shown, the steel cylinder 1 containing high-efficiency liquefied petroleum gas is provided with two angle valves 2, which are respectively used for exhaust and liquid discharge. One angle valve ...

Embodiment 2

[0013] Transport 5,000 grams of steel cylinder 1 with a volume of 12 liters to the gas filling station to fill with 2,000 grams of mother liquor (the mother liquor is propane), and use a plastic spoon to put 1.0 grams of catalyst manganese, neodymium, iron alloy powder into the cylinder angle valve exhaust port 6, Connect the special filling gun and open the angle valve 2 of the steel cylinder, inject 100 grams of gasoline into the steel cylinder 1 (the catalyst follows into it), and then inject 1000 grams of hydrogen peroxide into the steel cylinder 1. When the temperature is -40 ° C, it is necessary to add 5% anti Refrigerating agent ethanol, close angle valve 2, promptly make required " efficient liquefied petroleum gas " of 3101 grams.

Embodiment 3

[0015] Transport 5,000 grams of 12-liter liquid-phase steel cylinder 1 with a metal intubation to the filling station and add 1,800 grams of mother liquor (the mother liquor is propylene), and use a plastic spoon to add up the catalyst manganese-neodymium-iron alloy powder and copper oxide. Put 0.8 grams into the cylinder angle valve exhaust port 6, connect the special liquid gun and open the cylinder angle valve 2, inject 90 grams of petroleum ether and gasoline into the cylinder 1 (the catalyst follows into it), and then add hydrogen peroxide 900 gram into the steel cylinder 1, when the temperature is below -20°C, 4% antifreeze ethanol needs to be added, and the angle valve 2 is closed to obtain 2790.8 grams of the required "high-efficiency liquefied petroleum gas".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com