Resource treatment method for urban sludge

A technology for municipal sludge and treatment methods, which is applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc. Disposal and other problems, to achieve the effect of easy incineration disposal, enhanced degradability, and improved combustion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

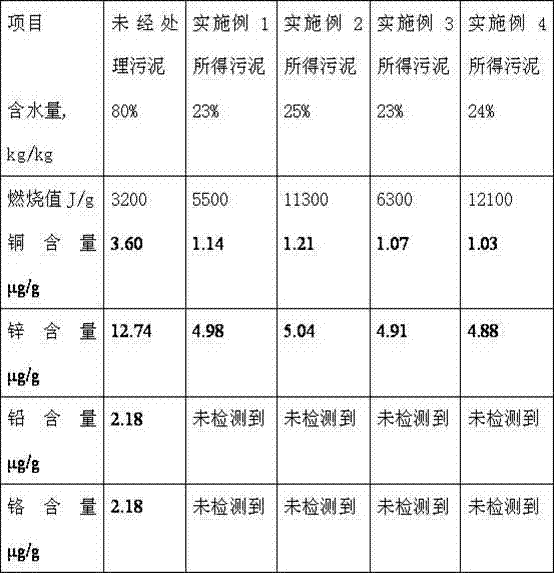

[0025] Weigh 1 kg of urban sludge (combustion value about 3200 J / g) that has been filtered through a filter press to a water content of about 80%, put it into an ultrasonic instrument with a capacity of 2 L, and perform ultrasonic treatment at a frequency of 900-950MHz After 50 minutes, transfer it to the extruder and heat it after airtight. When the internal gas temperature reaches about 150 ℃ and the pressure reaches about 3 atm, quickly open the extruder cover. After cooling to room temperature, take out the sludge and measure the water content as 23%, combustion value 5500J / g, pathogenic bacteria, parasites and other harmful microorganisms are basically completely inactivated after ultrasonication and puffing; and the content of exchangeable copper (Cu) and zinc (Zn) drops to about 30% of the original, The content of exchangeable lead (Pb) and cadmium (Cd) in the sludge after expansion and combustion is close to trace, and the detection results are shown in Table 1.

Embodiment 2

[0027] Weigh 1 kg of urban sludge filtered through a filter press to a water content of about 80%, add 20% of the sludge mass of sodium bicarbonate leavening agent and mix evenly, and put it into a 2 L capacity ultrasonic instrument. Ultrasonic treatment at a frequency of 900-950MHz for 30 minutes, then transferred to the extruder, sealed and then heated, when the internal gas temperature reached about 150 ℃ and the pressure reached about 3 atm, quickly opened the cover of the extruder, and cooled to room temperature , just take out the sludge, and the test results are shown in Table 1.

Embodiment 3

[0029] Weigh 3 kg of urban sludge filtered through a filter press to a water content of about 80% and put it into a 6 L ultrasonic instrument, ultrasonically treat it at a frequency of 915 MHz for 50 minutes, and then transfer it to an extruder. Heat it after airtight, and when the internal gas temperature reaches about 140 °C and the pressure reaches about 4 atm, quickly open the cover of the extruder, and take out the sludge after cooling to room temperature. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com