Preparation method of aluminum foil composite packaging material

A composite packaging material and composite material technology are applied in the field of preparation of aluminum foil composite packaging materials, which can solve the problems of polluted contents, solvent residues, influence on ecological environment and human health, etc., and achieve the effect of good composite strength and good peel strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing an aluminum foil composite packaging material, comprising the following steps:

[0026] Coating solvent-free adhesive to the substrate surface, the substrate is paper or high molecular polymer film, the sizing amount of the solvent-free adhesive is 2.4g / m 2 ~3.0g / m 2 ;

[0027] Composite the base material coated with the solvent-free adhesive and the aluminum foil, and the composite tension during the composite is 75N-85N;

[0028] Winding up the obtained composite material;

[0029] The rolled composite material is subjected to aging treatment to obtain an aluminum foil composite packaging material.

[0030] In the invention, the solvent-free adhesive is firstly coated on the base material, then compounded with aluminum foil, and the aluminum foil composite packaging material is obtained after winding and aging treatment. The invention obtains the aluminum foil composite packaging material with good performance by contr...

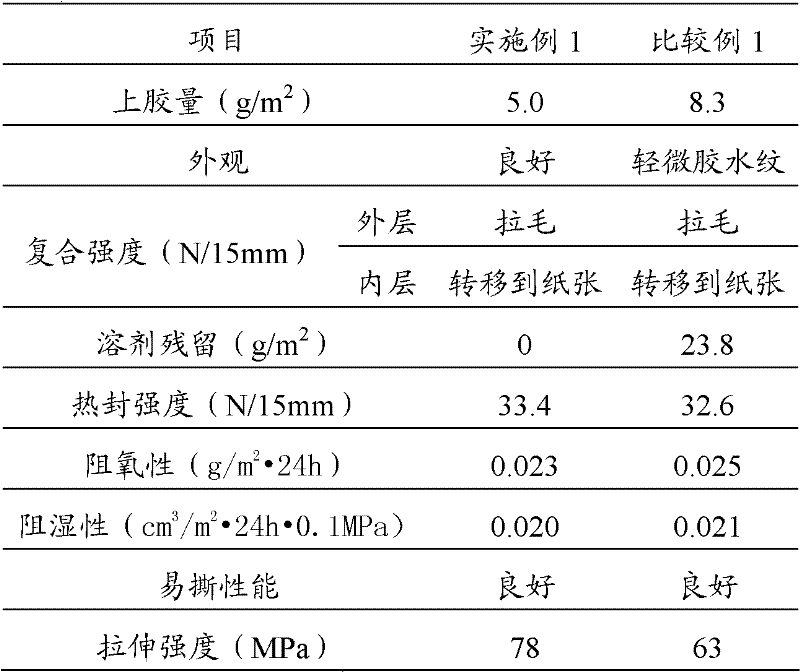

Embodiment 1

[0055] With 40g of food paper as the base material, the surface of the food paper is coated with a solvent-free adhesive of UR7515 produced by Henkel, Germany. The coating temperature is 45°C and the amount of glue applied is 2.4g / m 2 , the unwinding tension of the food paper is 18N; the food paper coated with the solvent-free adhesive is compounded with aluminum foil to obtain a composite material, the composite tension is 80N, and the unwinding tension of the aluminum foil is 2N; 25%; the composite material after winding is cured for 30h under the condition that the humidity is 75RH% and the temperature is 45°C, to obtain a food paper / aluminum foil composite film;

[0056] With the food paper / aluminum foil composite film as the base material, the surface of the aluminum foil is coated with a solvent-free adhesive of UR7515 produced by Henkel, Germany. The coating temperature is 45° C. m 2 , the unwinding tension of the food paper / aluminum foil composite film is 12N; the foo...

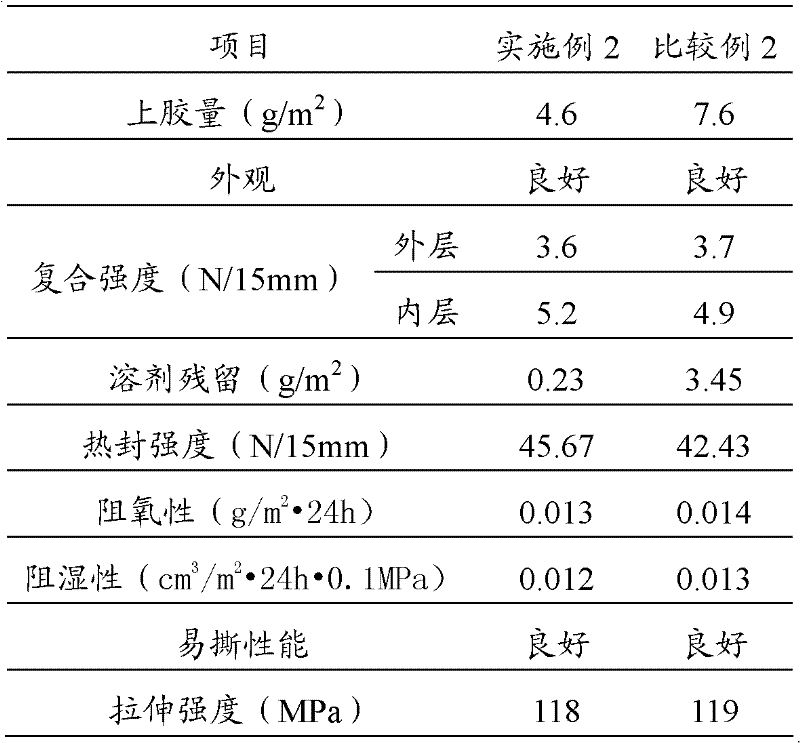

Embodiment 2

[0065] With a 12 μm thick PET film as the base material, the surface coating of the PET film produced by Henkel, Germany, the brand is the solvent-free adhesive of Liofl UR7750 / UR6071, wherein the mass ratio of 7750 and 6071 is 6: 1, The coating temperature is 45°C, and the amount of glue is 2.6g / m 2 , the unwinding tension of the PET film is 18N; the PET film coated with the solvent-free adhesive is compounded with aluminum foil to obtain a composite material, the composite tension is 80N, and the unwinding tension of the aluminum foil is 2N; the composite material is rewound, and the rewinding taper 25%; the composite material after winding was matured for 86 hours at a humidity of 45RH% and a temperature of 55°C to obtain a PET / aluminum foil composite film;

[0066] With the PET / aluminum foil composite film as the base material, the surface of the aluminum foil is coated with a solvent-free adhesive of Liofl UR7750 / UR6071 produced by Henkel, Germany, wherein the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glue amount | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

| Unwind tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com