Pipe fitting expanding device

A technology of equipment and pipe fittings, which is applied in the field of pipe fittings flaring equipment, can solve the problems of unsightly finished products, high cost, and low efficiency of thermal flaring processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above-mentioned features and advantages of the present invention more comprehensible, exemplary embodiments are given below together with accompanying drawings and described in detail as follows.

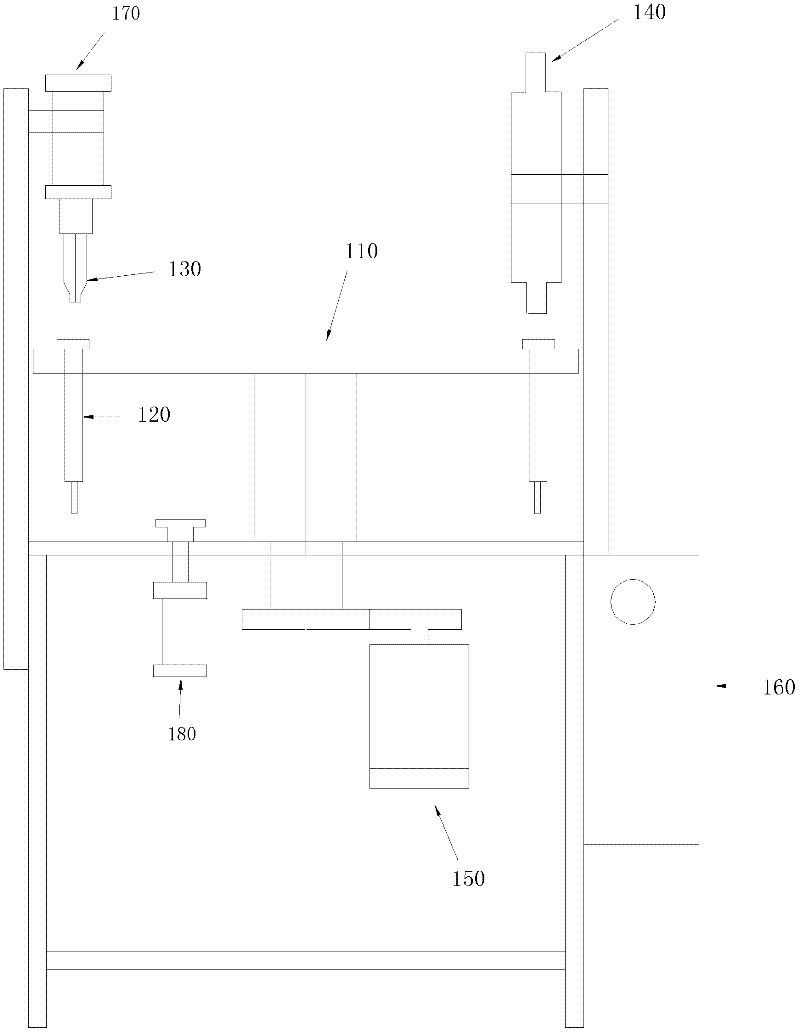

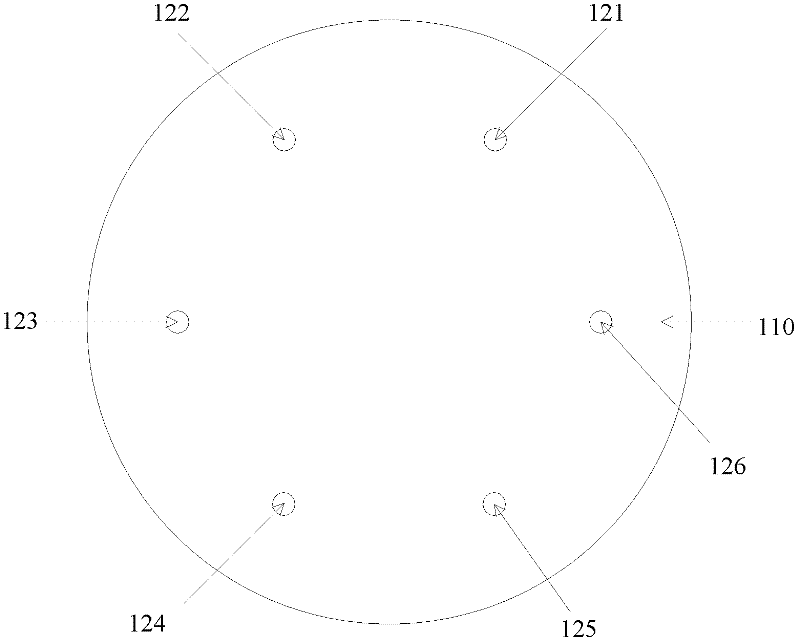

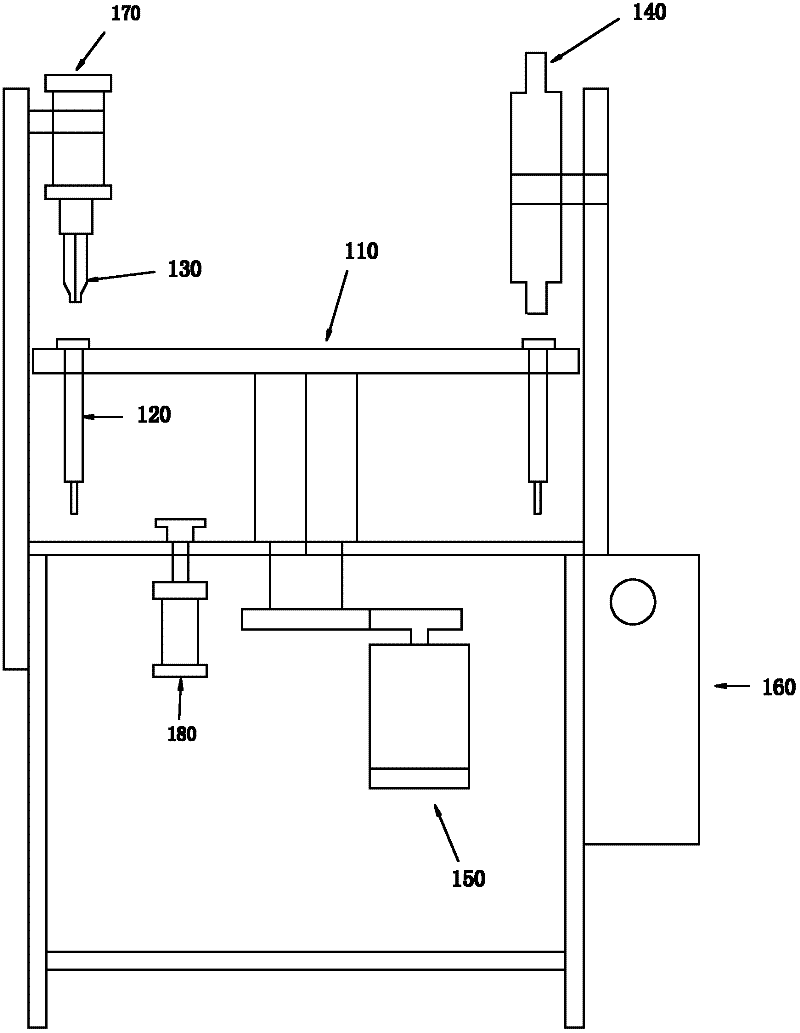

[0017] Please refer to figure 1 , which is a structural schematic diagram of a pipe flaring device provided by an embodiment of the present invention. As shown in the figure, the apparatus includes a table 110 , a lower mold 120 , an upper mold 130 , a heater 140 , a rotating motor 150 and a controller 160 . The lower mold 120 is arranged on the workbench 110 for storing pipes to be flared; the upper mold 130 and the heater 140 are arranged above the workbench; the rotating motor 150 is connected with the workbench 110 to drive the workbench to rotate. The controller 160, as the core of the flaring equipment, is used to coordinate the orderly work among various components and realize flaring automation. Specifically, the controller 160 controls the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com