Method for automatically analyzing sulfide in water sample

An automatic analysis and sulfide technology, which is applied in the direction of chemical reaction of materials for analysis, preparation of test samples, color/spectral characteristic measurement, etc., can solve the problems of complex operation and low accuracy, and achieve a wide linear range , Eliminate the difference in absorbance and the effect of good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this example, a standard sample was tested to examine the precision of the method of the present invention. The steps are as follows:

[0033] 1. Preparation of standard samples

[0034] (1) 0.7491g Na 2 S·9H 2 Dissolve O in deionized water, make up the volume to 100ml, refrigerate in the refrigerator for use, and calibrate when using, the calibration concentration is 835.516mg / L S 2- mother liquor;

[0035](2) Dilute the mother liquor with deionized water to prepare a standard sample with a sulfide concentration of 0.8355 mg / L.

[0036] 2. Preparation of color developer R

[0037] Take 35 mL of Alizarin Red S aqueous solution with a concentration of 0.01 mol / L and dilute to 500 mL. After mixing the prepared Alizarin Red S and Britton-Robinson buffer in equal volumes, add NaOH with a concentration of 0.2 mol / L, and use a pH meter to accurately adjust the pH of the mixed solution = 4.4. The concentration of Alizarin Red S is: 7.0×10 -4 mol / L of color developer...

Embodiment 2

[0044] In this example, the tested samples were river water and hot spring water, which were filtered through medium-speed filter paper for analysis. The analysis steps are as follows:

[0045] 1. Preparation of standard samples

[0046] (1) 0.7491g Na 2 S·9H 2 Dissolve O in deionized water, make up the volume to 100ml, refrigerate in the refrigerator for use, and calibrate when using, the calibration concentration is 835.516mg / L S 2- mother liquor;

[0047] (2) Dilute the mother liquor with deionized water and prepare a series of standard samples. The concentrations of sulfide in each standard sample are: 0.008355mg / L, 0.0167mg / L, 0.03340mg / L, 0.05013mg / L, 0.06680mg respectively / L, 0.08355mg / L, 0.25065mg / L, 0.41775mg / L, 0.6684mg / L, 0.8355mg / L, 1.671mg / L, 2.5065mg / L, 3.3420mg / L.

[0048] 2. Preparation of color developer R

[0049] Take 40 mL of Alizarin Red S aqueous solution with a concentration of 0.01 mol / L and dilute to 500 mL. After mixing the prepared Alizarin R...

Embodiment 3

[0062] In this example, the tested sample was the same as that in Example 2, and was analyzed after being filtered through medium-speed filter paper. The analysis steps are as follows:

[0063] 1. Preparation of color developer R

[0064] Take 45 mL of Alizarin Red S aqueous solution with a concentration of 0.01 mol / L and dilute to 500 mL. After mixing the prepared Alizarin Red S and Britton-Robinson buffer in equal volumes, add NaOH with a concentration of 0.2 mol / L, and use a pH meter to accurately adjust the pH of the mixed solution to 4.80. The concentration of Alizarin Red S is: 9.0×10 -4 mol / L of color developer R.

[0065] 2. Use deionized water to push liquid C.

[0066] 3. Test drawing of sample spectrum

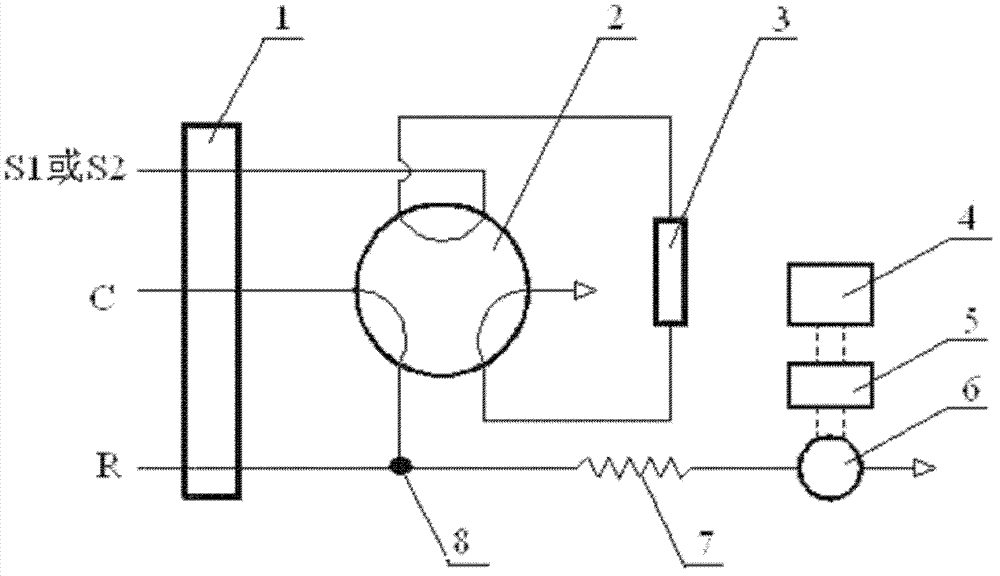

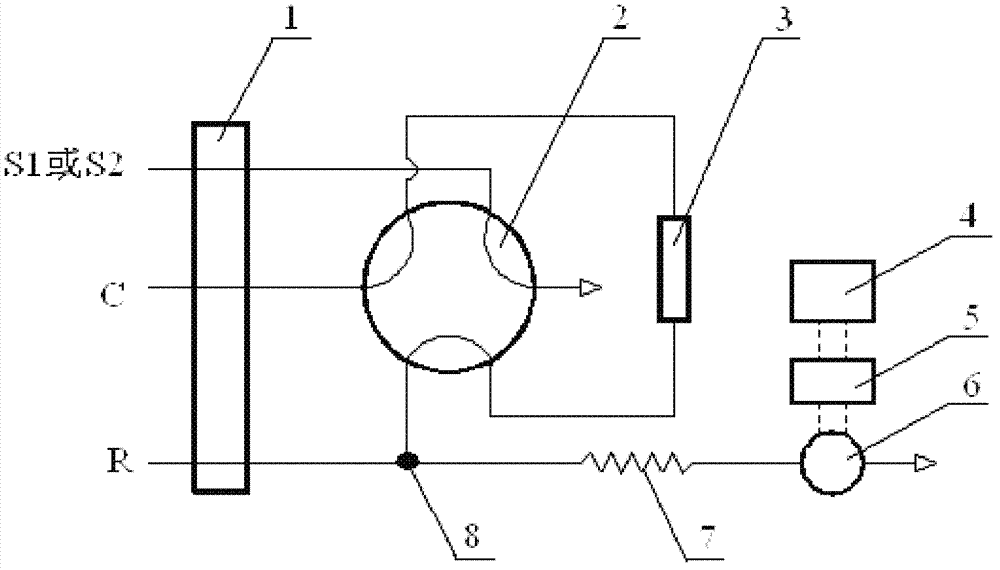

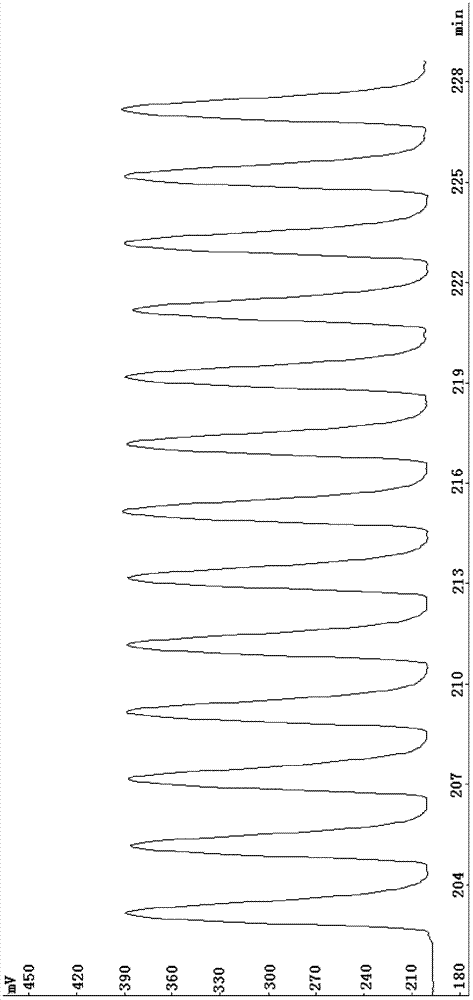

[0067] use figure 1 The automatic analyzer designed for the shown process flow is tested. The low-pressure pump 1 in the instrument is a four-channel constant-flow pump, the pump flow rate is 0.4~1.0ml / min, and the working pressure is 2~3×10 5 Pa. The optica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com