High-temperature pressure and temperature compounded sensor and preparation method thereof

A composite sensor and high-temperature technology, which is applied in thermometers, the measurement of the properties and forces of piezoresistive materials, and thermometers using electric/magnetic elements that are directly sensitive to heat, etc., to achieve high reliability, small specific gravity, and manufacturing process. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

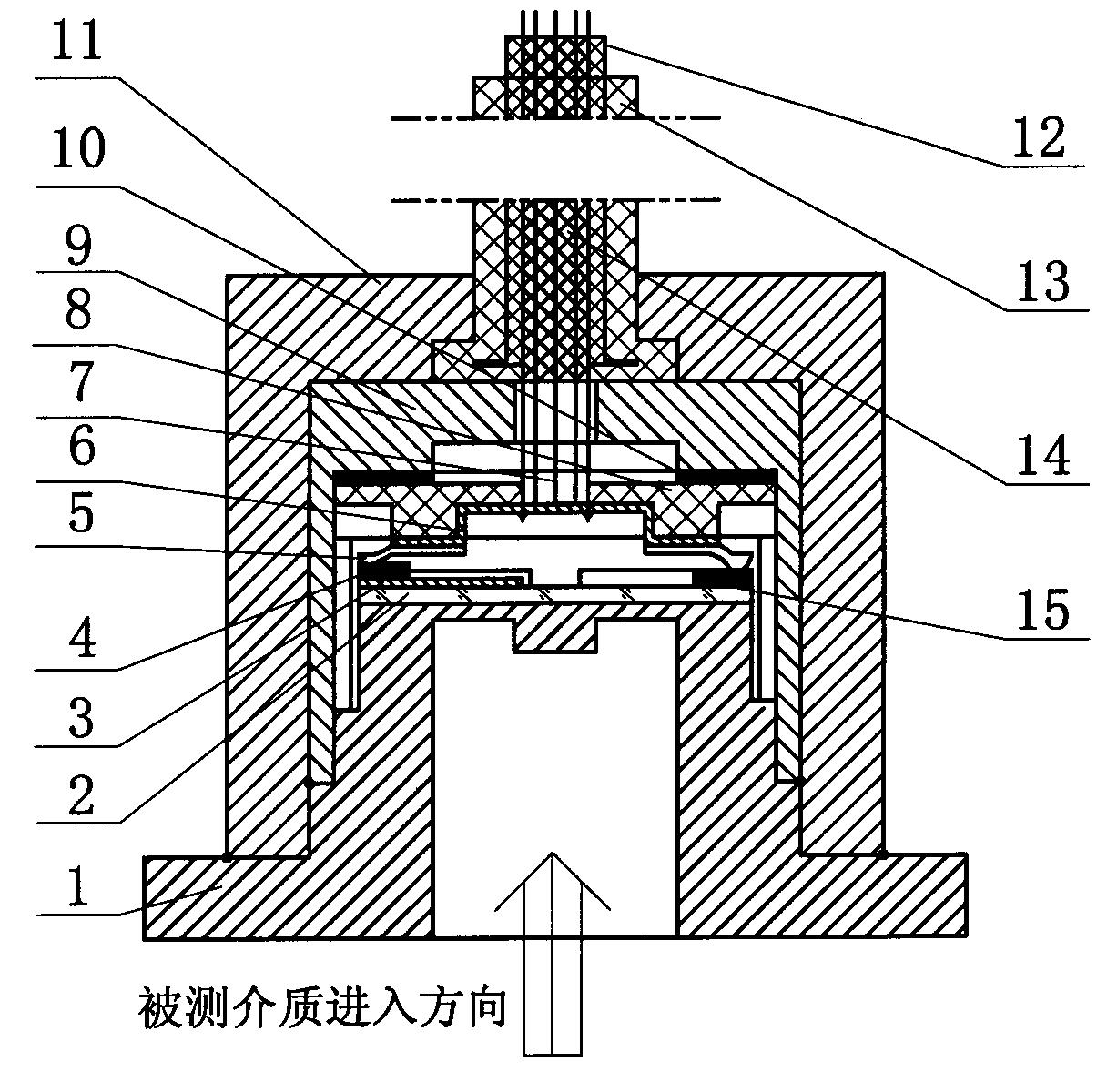

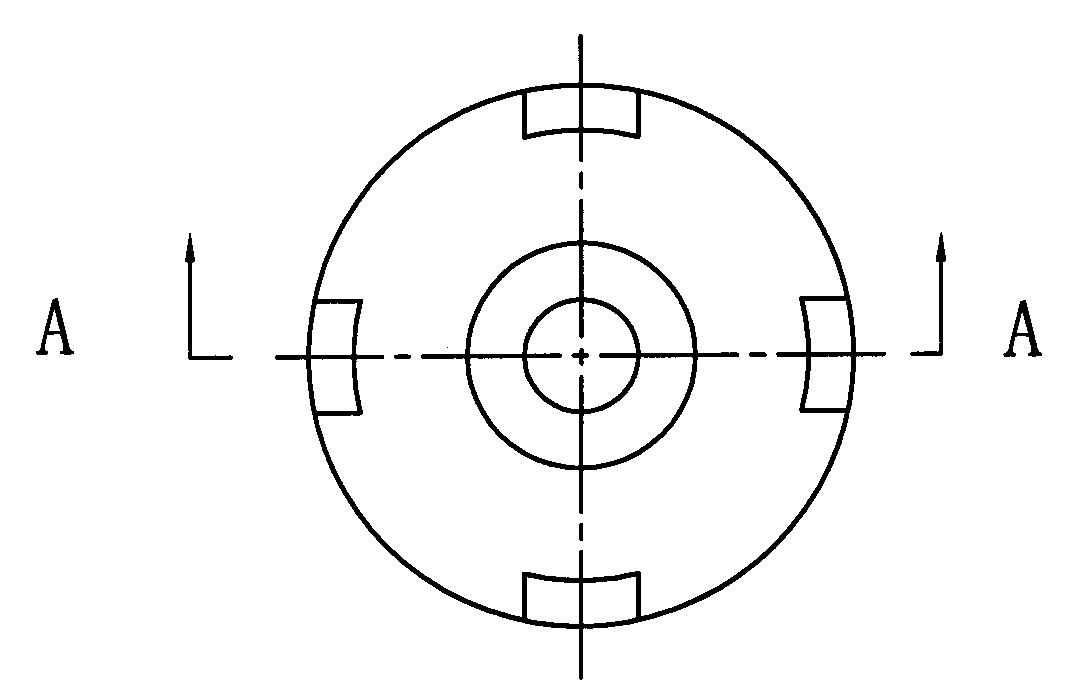

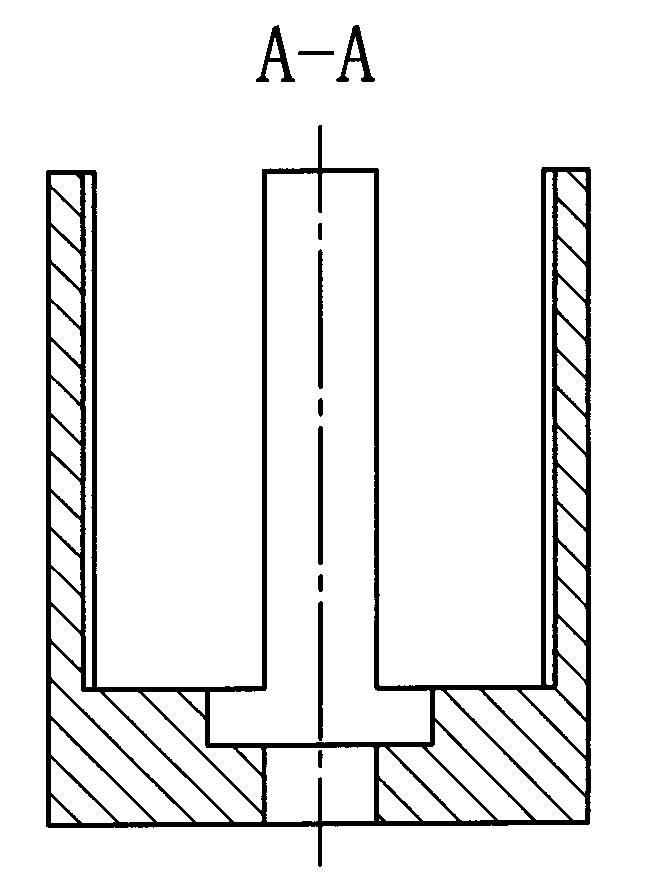

[0036] according to Figure 1-7 The specific structure and preparation method of the present invention will be described in detail. The composite sensor of high temperature pressure and temperature includes sapphire wafer 2 and titanium alloy stress cup 1, platinum pad 4, insulated lead conversion plate 8, titanium fixing claw 9, outer lead 7 and Titanium alloy casing 11 and other parts. Among them, the center of the symmetry axis of the titanium alloy stress cup 1 (the inner diameter of the stress cup) is positioned, and a platinum thermistor 15 is provided in the corner of the non-stress area on the same sapphire wafer 2 on which the silicon strain resistance 3 and the platinum pad 4 are made in the stress area. . The inner cavity of the titanium fixing claw 9 welded on the titanium alloy stress cup 1 is sealed with an insulated lead conversion plate 8 by means of a silver brazing layer 10 . One end of the metal foil strip 5 used as the inner lead is welded on the platinu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com