Mixed filling type thermal conductive silicone rubber composite and preparation method thereof

A technology of heat-conducting silicone rubber and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of small thermal conductivity and achieve the effect of improving thermal conductivity and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

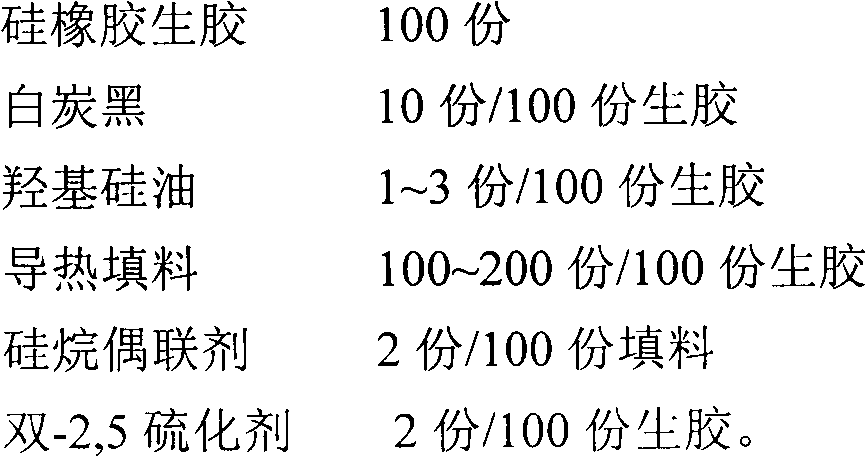

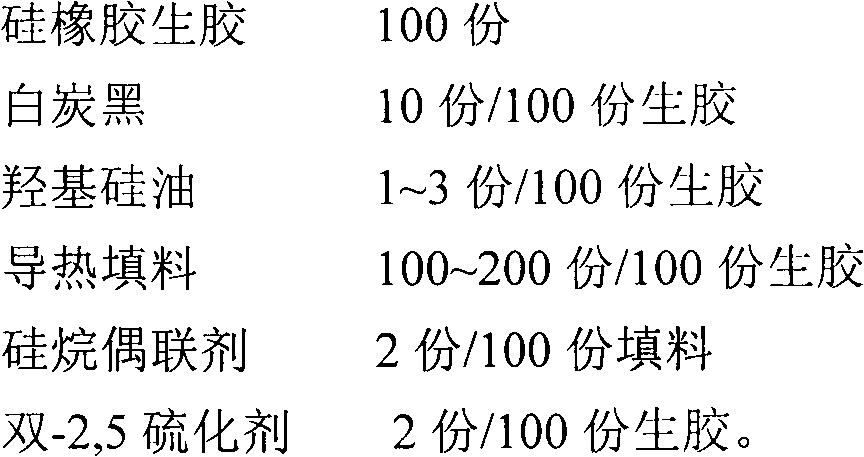

Method used

Image

Examples

Embodiment 1

[0021] Add 100 parts by mass of methyl vinyl silicone rubber raw rubber with a vinyl molar fraction of 0.13% to 0.22% to the rollers of the double-roll mill, and add 10 parts by mass of precipitated white carbon black after wrapping the rolls, Then add 2 parts by mass of hydroxyl silicone oil, followed by 100 parts by mass of filler and γ-aminopropyltriethoxysilane accounting for 2% of the filler mass. The thermally conductive filler is a mixed powder of SiC and AlN, wherein the SiC powder The average particle size of AlN powder is 10 μm, the average particle size of AlN powder is 1 μm, and the mass ratio of SiC and AlN is 3:1. Repeatedly knead until uniform, and finally add 2 parts by mass of bis-2,5 vulcanizing agent, continue to knead evenly, and obtain the silicone rubber compound.

[0022] Put the kneaded silicone rubber into the mold, and after filling the mold with cold pressure, place the mold on a flat vulcanizer for a stage of vulcanization. The vulcanization tempera...

Embodiment 2

[0026] Add 100 parts by mass of methyl vinyl silicone rubber raw rubber with a vinyl molar fraction of 0.13% to 0.22% to the rollers of the double-roll mill, and add 10 parts by mass of precipitated white carbon black after wrapping the rolls, Then add 2 parts by mass of hydroxyl silicone oil, followed by 200 parts by mass of filler and γ-aminopropyl triethoxysilane accounting for about 2% of the filler mass. The thermally conductive filler is a mixed powder of SiC and AlN, wherein the SiC powder The average particle size of AlN powder is 10 μm, the average particle size of AlN powder is 1 μm, and the mass ratio of SiC and AlN is 3:1. Repeatedly knead until uniform, and finally add 2 parts by mass of bis-2,5 vulcanizing agent, continue to knead evenly, and obtain the silicone rubber compound;

[0027] Put the kneaded silicone rubber into the mold, and after filling the mold with cold pressure, place the mold on a flat vulcanizer for a stage of vulcanization. The vulcanization ...

Embodiment 3

[0031] Add 100 parts by mass of methyl vinyl silicone rubber dust with a vinyl mole fraction of 0.13% to 0.22% to the rollers of the double-roll mill, and add 10 parts by mass of precipitated white carbon black after wrapping the rolls. Then add 2 parts by mass of hydroxyl silicone oil, followed by 200 parts by mass of filler and vinyltriethoxysilane accounting for 2% of the filler mass. The thermally conductive filler is a mixed powder of SiC and AlN, and the average particle size of the SiC powder is The diameter is 10 μm, the average particle size of AlN powder is 1 μm, and the mass ratio of SiC and AlN is 3:1. Repeatedly knead until uniform, and finally add 2 parts by mass of bis-2,5 vulcanizing agent, continue to knead evenly, and obtain the silicone rubber compound;

[0032] Put the kneaded silicone rubber into the mold, and after filling the mold with cold pressure, place the mold on a flat vulcanizer for a stage of vulcanization. The vulcanization temperature is 162°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com